API 6D Forged Steel Flanged Trunnion Ball Valve (Q47F)

| Price: |

US $ 15-275/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Piece |

| Pay Type: |

L/C,T/T |

| Prod Model: |

Q47F |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

2" to 40" |

| Class: |

150lb to 2500lb |

| Certificates: |

API 6D, CE, ISO9001 |

| Application Fields: |

Metallurgy,Light Industrial,Electric Power,Petroch |

| Delivery Detail: |

20~45 Days According to The Specific Quantities |

| Connection Form: |

Flange |

| Channel: |

Straight Through Type |

| Structure: |

Floating Ball Valve |

| Type: |

Fixed Ball Valve |

| Application: |

Water Industrial Usage |

| Material: |

Forged Steel |

| Nominal Pressure: |

150lb to 2500lb |

Product Description

Forged Steel Flanged Ball Valve (Q47F)Two Pieces/Three PiecesForged Steel Body

Trunnion Mounted Ball, Full&Reduced Bore

Anti-static Device

Blow-out Proof Stem

Doouble Block and Bleed

Fire Safe Design

Emergency Sealant Injector

Vent Valve, Drain Valve

Lifting lugs and supporting feets(8" & larger)

Design: ASME B16.34/API 6D

Face to Face: ASME B16.10/API 6D

End Flange: ASME B 16.5

BW End: ASME B16.25

Test: API 6D

Fire Safe Test: API 607/API6FA

Special: NACE MR-01-75

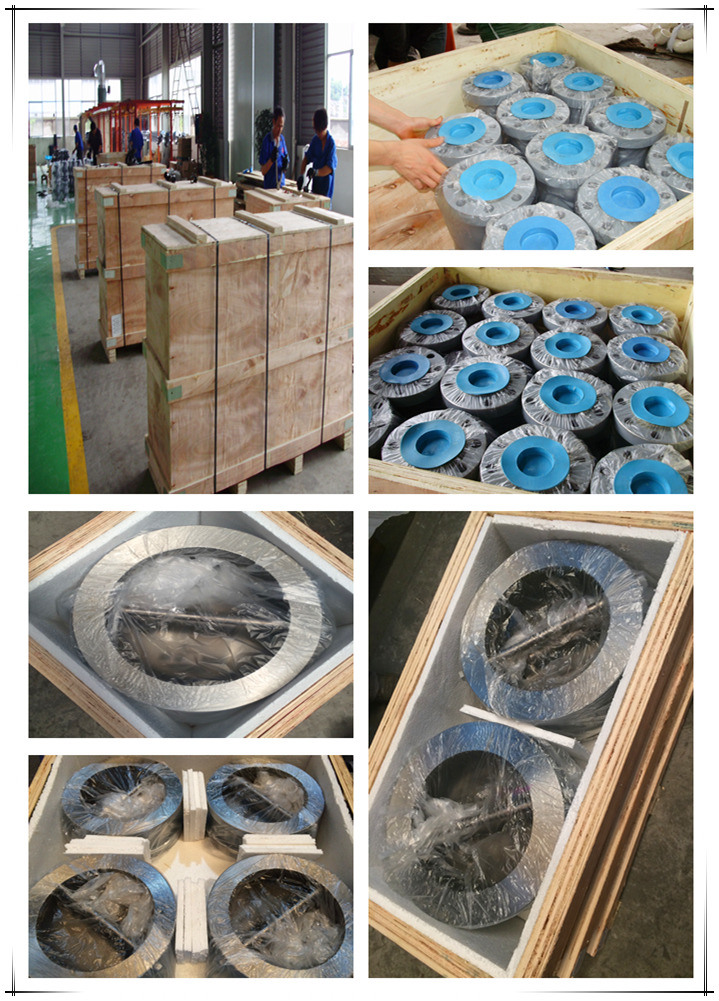

PRODUCTS WORKSHOP

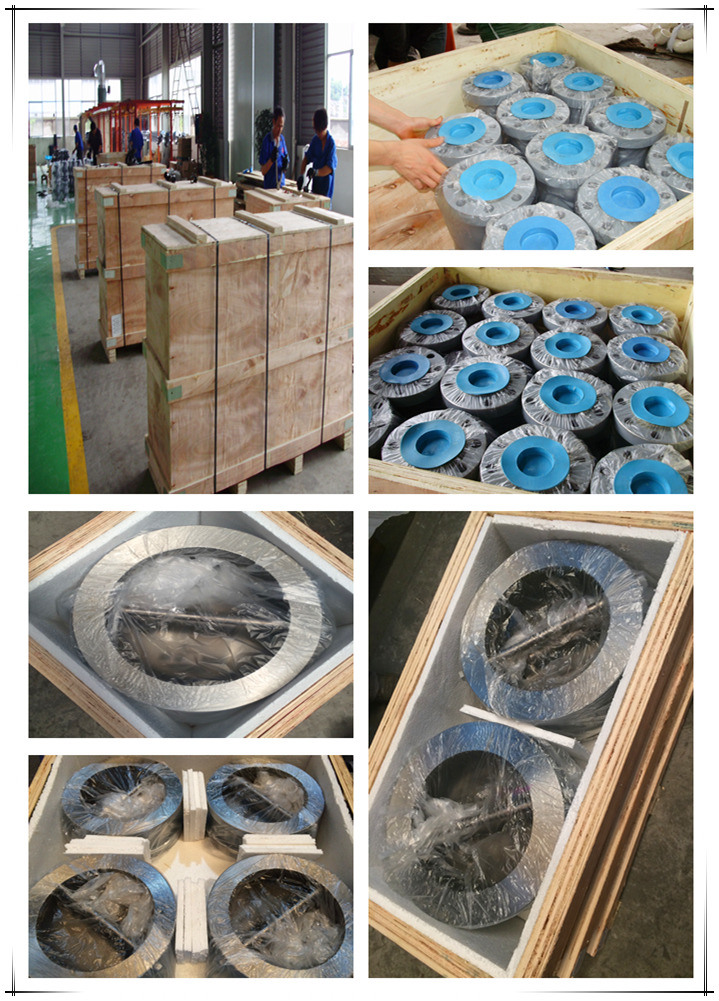

WORKSHOP PACKING

PACKING We welcome all the world customers to contact us for more cooperation.With our years of technical knowledge and experience,we assure you,Naibang will be one of your best parters in China.

We welcome all the world customers to contact us for more cooperation.With our years of technical knowledge and experience,we assure you,Naibang will be one of your best parters in China. | NO. | Part | Material |

| 1 | Bonnet | ASTM A105+ENP A182-F304,F316,F316L,F6,F51 |

| 2 | Seat Spring | Inconel X-7505 SS304 SS316 |

| 3 | Seat | PTFE RPTFE PEEK PPL |

| 4 | Seat Injection | 1020+ZN A182-F304,F316,F316L |

| 5 | Body | ASTM A105 A182-F304,F316,F316L,F304L,F51 |

| 6 | Screw | ASTM A193-B7,B8 |

| 7 | Top Flange | ASTM A105 A182-F304 |

| 8 | O-ring | NBR Vtion |

| 9 | Key | 1045 A182-F304,F316,F316L,F304L |

| 10 | Stem | A105+ENP A182-F6,F304,F316,F316L,F304L,17-4PH,F51 |

| 11 | Vent Valve | 1020+ZN A182-F304,F316,F316L |

| 12 | Stem Injection | 1020+ZN A182-F304,F316,F316L |

| 13 | Sliding Bearing | Stainless Steel+PTFE SS316+PTFE |

| 14 | Thrust Washer | PTFE |

| 15 | Seat Ring | A105+ENP A182-F6,F304,F316,F316L,F304L,F6,F51 |

| 16 | Stud | ASTM 193-B7,B7M,B8,B8M |

| 17 | Nut | ASTM 194-2H,2HM,8,8M |

| 18 | Body Gasket | PTFE SS304+Graphite SS316+Graphite |

| 19 | Ball | A105+ENP ASTMA182-F6,F304,F316,F316L,F51 |

| 20 | Lower Gasket | PTFE |

| 21 | Drain Valve | 1020+ZN A182-F304,F316,F316L |

| 22 | Antistatic Spring | Stainless Steel SS316 |

| 23 | Trunnion | A105+ENP ASTMA182-F6,F304,F316,F316L,F51 |

| 24 | Seat Sealing | Graphite |

| 25 | Gand Gasket | SS304+Graphite |

| 26 | Bottom Cover Gasket | SS304+Graphite |

Zhejiang NaiBang Valve Co., Ltd. is a specialized company devoted into manufacture and sales of valves, the company situates in ou-bei town-the center of China's pumps & valves, with ground area 18800m2, machine workshop, assemble workshop and synthetic finished half - finished warehouse. The company possesses 210 precise equipments, the advanced numeral control machines ensure the flexibility and exchangeability of all the product parts. The company flourishes year by year, and its products have been widely used in lines of domestic large PowerStation configuration, dirty water processing, urban construction, petroleum-chemical, oil extraction, metallurgy, chemical fertilizer, paper production and pharmacy, exported to many countries and regions, gains the users' unanimous praise and confidence.

The company has a modernized staffs of tech research and product development, ISO9001 certificated. And now the company has the capability of manufacturing big series of high temperature and hi-gh pressure power station gate valve, ball valve, globe valve, check valve, butterfly valve, with the strength of API valve, Wafer check valve and forged valve, and the wafer check valve mainly cover wafer single disc lift and swing check valves and wafer double disc swing check valves (H77, H76, H74, H72, H71, H46 and H44). Diameter of valves varies from DN15 to DN2000(1/2'-72' ), working pressure varies from PN1.6MPa to 42 MPa(150lb to 2500lb), and working temperature from -196 Celsius degree to +570 Celsius degree; The main body adopts WCB, WC6, WC9, Cr5Mo, 20Crmo, 12Crmov, 15Crmov, CF3m, CF8m. The company possesses full precise casting equipments, integrated physical and chemical gauges, experimentation equipments and test methods, as well CAD design capability, which ensure products always in high quality.