| Prod Model: |

F51 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Body Material: |

A105n; F11; F22; F304 |

| CNC Lathe: |

Finishing Machining |

| Dimensions: |

Various |

| Coatings: |

Black Oxide |

| Inspection: |

Third Party Accept |

| Processing Object: |

Metal |

| Molding Style: |

Forging |

| Forging Tolerance: |

as Customer' S Request |

| Certification: |

API/Q1 |

Product Description

API CERTIFIED SUPPLIER Forged Valve Bonnet

Specifications

Forged pressure sealed valve bonnets are widely applied in the industry of power plant.1. Available Material can be: A105, LF2, F11, F22, F5, F9, F304, F316, F321, Duplex stainless steel (F51), Super duplex stainless steel (F53, F60);2. Designed and processed by CNC machine.

3. All big and small angles are well finished.

4. Precision alignment sleeves positively locate the rod cap, maintaining big end bore size and eliminating cap walk.

5. X-rayed, sonic tested and magnafluxed.

6. Multi-stage heat treated.

7. Shot peened to relieve stress.

8. Come with the bronzed bushing suitable for the floating piston pin.

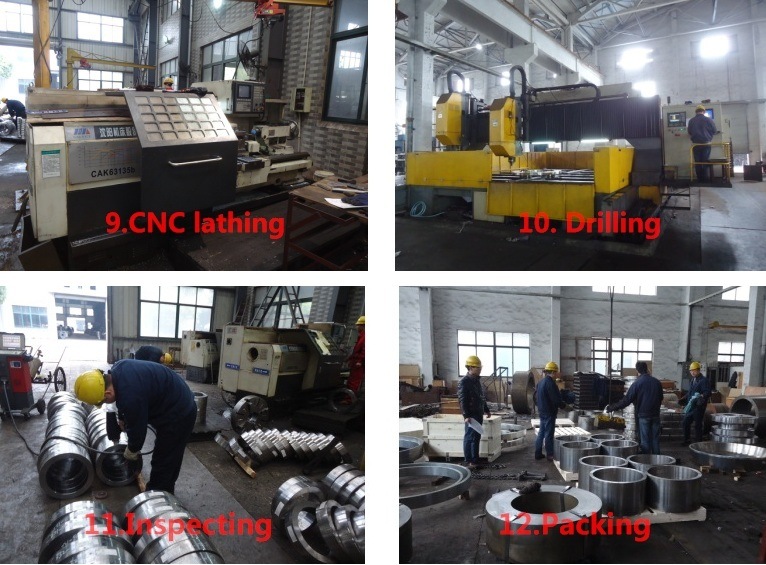

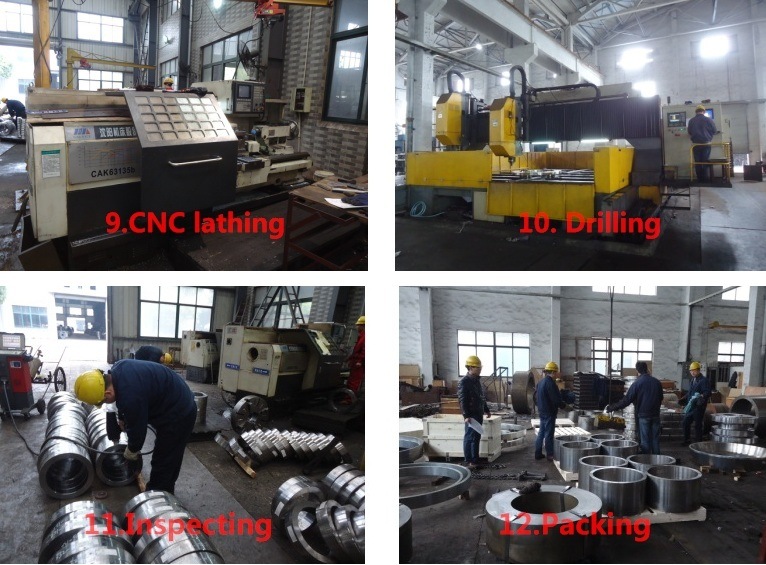

Manufacturing process:

All different forging products are as per customer's drawing.

All different forging products are as per customer's drawing.

Hongfeng can provide the products with the single weight up to 11mt and diameter up to 3m, such as tube sheets, rings, cylinder and shafts, etc. The material includes Austenitic stainless steel, Martensitic stainless steel, Duplex Stainless Steel, Carbon steel and Alloy steel. Their products widely used in transmission, mould, metallurgy, petrochemical, valve, shipbuilding, and cars. Our company has more than 18years experience, with the ability to provide a series service of blanking, heating, forging, heat-treatment, CNC, inspection, surface-treatment, packing and shipping.

Since establishment, Hongfeng develops year by year; The main equipments are as below: 1 set for each 11mt & 5mt electro-hydraulic hammers, 1set for each 3mt, 1.5mt, 1mt and 750kgs air hammers; 5 sets of gas heat furnaces; 3sets of electrical heat treatment furnaces; 2 sets for each 16mt&10mt and 4sets of 5mt cranes; 5 sets of Large sawing machines ( the sawing length up to 3m), 12sets of common sawing machines; 4sets of vertical lathes(¢ 3m*2.5m), 3sets of 10m*¢ 1.4 and 8sets of 1m*¢ 800mm horizontal lathes. The production capacity can reach 20000mt; The products are strictly according to the standard. From the beginning to the end of every order, we have detailed records for every process.