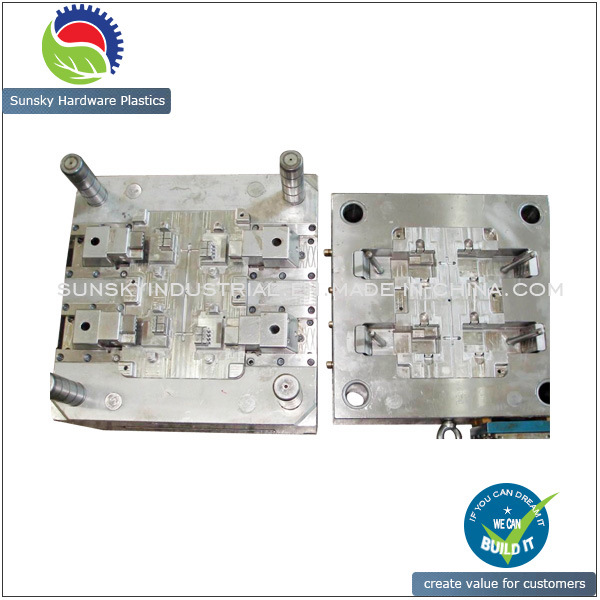

Specifications| Item Name: | plastic molding parts & injection part |

| 1. Material | ABS, flame-resistant ABS,PC,PS,PP,PVC,TPR,TPU,TPE , HDPE,PMMA etc |

| 2. Mould Cavity | Single or multi-cavities |

| 3. Mold base | LKM or Equivalent standard mould base |

| 5. Surface Finish | lNAK 80 prehardened steel,718, 718H,H13 etc. |

| 5. Surface Finish | chrome plating, silk-printing, Laser etching, texture, color painting etc. |

| 6. Injection Matching Size | 20 sets range from 120T To 850T |

| 7. Max Mould Size | 1700×1700mm |

| 8. Max Product Size | 1200×1200mm |

| 9.Surface Treatment | Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc. |

| 10.Mould Leadtime | 20-30 days depending on the size of the products |

| 12.Injection Maching Size: | 15-30 days depending on the quantity of the order |

| 12.Injection Maching Size | 20 sets range from 120T to 850T |

| 13. Mold Life | 50,000shots to 500,000shots |

| The product in the pictures are our customers' OEM products, for reference only. |

Plastic Molded Parts 1.Professional manufacturer

2.Certificates: ISO 9001:2000

3.High quality,best prices and quick delivery

Plastic Injection Solution:1. Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production

2. Parts are widely used: Industrial, Automotive, Electronics & Medical

Technical Skills - Development, Design Skills1. Design Consultation & Assistance

2. Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysis

Material Selection Assistance1. Quick turn-around prototype support

2. Secondary Operations including machining, welding & assembly

Molding - High Precision, High Concern1. Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping

2. 40 Molding machines from 80TONS to 1400TONS

3. High precision molding from medical to fiber optics components

Secondary Operations - Value Added Service1. Pad Printing

2. Sonic Welding

3. Assembly & Packaging

Our Professinal injection mold service: 1. Automobile mold

2. Gear mold

3. Cap mold

4. Unsrewing mold

5. Overmold, overmolding, Two Shot Over-Molding, Two Color Over-Molding, Insert Over-Molding

6. Hot runner mold

7. Injection molding

8. Stamping and die-casting mold

Company Advantage:1.Professional manufacturer

2. Advanced equipment and excellent R&D Team

3. Highly skilled manufacturing process

4. A variety of ODM&OEM product range

5. Strict quality Control System

6.Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM

7. Competitive price

Company ProfileWith plentiful experience and skillful technique, Dongguan Sunsky Hardware Plastic Co., Ltd. is specialized in doing double-injection molding, insert mould injection molding, plastic injection molding, one cavity and multi-cabity molding, plastic mold,etc in china. Our company is capable to produce plastic parts as per your drawings/ samples, and we also enjoy good reputation among our domestic and overseas market.

Company ProfileWith plentiful experience and skillful technique, Dongguan Sunsky Hardware Plastic Co., Ltd. is specialized in doing double-injection molding, insert mould injection molding, plastic injection molding, one cavity and multi-cabity molding, plastic mold,etc in china. Our company is capable to produce plastic parts as per your drawings/ samples, and we also enjoy good reputation among our domestic and overseas market.