Automatic Notebook PP Box Gluing Machine

| Price: |

US $ 150000-2000000/Set |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: |

CL-600/800 |

| Automatic Grade: |

Automatic High-Speed Folder Gluer |

| Type: |

Plastic Box Gluing Machine |

| Packaging Type: |

Wooden Case |

Product Description

Automatic Notebook PP Box Gluing Machine

( Box Bottom Locked)

Automatic Feeding, Automatic Folding, Automatic Bottom Locking, It can applied for PVC,PET,PP materials to glue transparent package boxes.It can glue on the outside/inside/middle of the boxes. All is depends on your requirements, Machine is suitable for both single line ( Die cutting line) and double line ( High Frequency making line)- Easy to operate and adjust the machine. One hex wrench can adjust most of the parts on the machine. Operation friendly.

- Humanized design, easy to control and fast speed.

- Machine uses the integral steel to make the machine structure firm and stable and compact. Easy to operate.

- Machine uses constant variable transmission and strong power motor to run this machine. It can run 120 M/ Min. Transmission Bet is top quality and durable, long life using, low noise, low wearing, easy to replace, saving your cost to maintain this machine.

- Machine modes are easy to change. Multi functional.

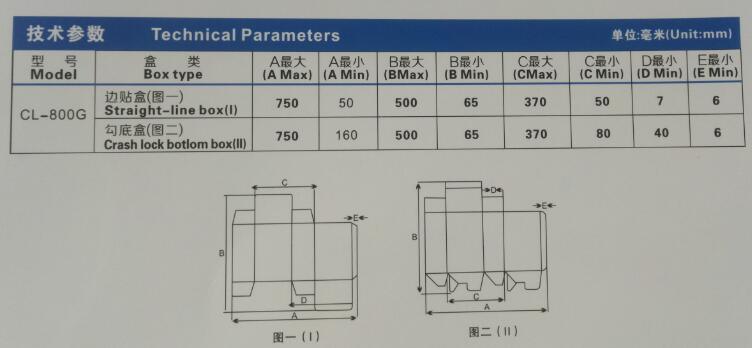

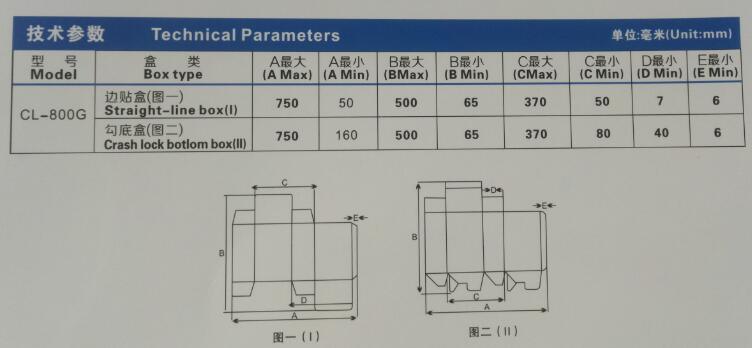

Different material box different size different shapes all can be done on this machine only by choose suitable mode. | Model | CL-800G | Glue Inject System | USA Nordson |

| Motor Brand | Taiwan ShengBang | Material Applied for | PET PVC PP |

| Solenoid Valve | USA MAC | Folding Line suitable for | Diecutting line /High Frequency Line |

| Inverter | Japan Panasonic | Gluing Size | Max.750mm Min.50mm |

| Power Supply | 380V 50-60HZ | Machine Running Speed | 120m/min |

| Total Power | 11 Kw | Machine Dimension | 160000*1500*1400mm |

| Relay | Japan Omron | Machine Weight | 7 Ton |

| PLC | Panasonic | Air Supply required | 0.7 m3/min |

13yrs on Plastic Box Folding & Gluing Machine (Auto Bottom)

Make your transparent or printed plastic box with premium look and crisp appearance for enhancing your unmatched shelf impact.

Shenzhen Cheng Lin Smart Technology Co., Ltd established in 2003, specialized in Automatic Folding and Gluing Machine, as well as Crash Lock Bottom Gluing machine.

Our company has own extruding sheet material system and adhesive material like PUR glue, water glue PET glue PVC glue etc.

With 13 years' experience on plastic box making we have strong R&D team to enhance product quality and production efficiency, can assure to provide customers one-stop service on other auxiliary equipment too like sheet flattening machine, high frequency machine for creasing or die-cut etc.

We have competitive advantage, customer service of quotation within 24hours, sample within 3days, production within 4weeks (subject to qty and situation). We are your reliable business partner, we welcome customers to visit and perform their own quality and social compliance audits.

We can also design tailor-made machines to make your special needs, plus our glue production and extruding sheet materials all production processes are completed under one roof here.

If you need humane-design, easy operate, adjust and maintain machine with automatic multi-functional high productivity, 24hours after-sale service with whole lifespan tech. Support.

We are your better choice!

1. Over 13yrs of market leadership on box-paste, box-folding machine auto high speed.

2. Exceptional customer service and flawless execution.

3. Using the finest quality components.

4. All machines are tailor-made for your different requests.

5. Customer service of quotation within 24hours.

6. Sample within 3days.

7. Production within 4 weeks (normally has stock)

Machine advantages:

1. Fully High Speed Auto feeding, Auto folding, Auto gluing for all kinds of plastic box shapes made from PET, PVC, PETG, JAJ (PP heat sealing) etc.

2. Brand name components and electronics with USA Nordson PUR glue spray equipment.

3. Flexible multi-functional, fast adjustment, easy operates and maintenance, low sound & high efficiency, defective rate below 1% to save your running and labor cost.

4. Can paste min. 0.018 to 1mm thickness plastic box which is die-cut single line or soft creasing double line.

5.4 in 1 functions (4 gluing systems can paste PP box with hot air, PET/PVC box with water glue, spray PUR glue, glue tiny box like eyeliner package etc. )