| Prod Model: |

DXGF-24-24-6 |

| Name: |

Carbonated Drink Filling Machine |

| After-Sales Service: |

Engineers Available to Service |

| Certification: |

Ce ISO SGS |

| Product Control: |

PLC Control |

| Bottle Volume: |

0.3L-2L |

| Warranty: |

12 Months |

| Main Material: |

SUS304/SUS316 |

| Material Type: |

Liquid |

| Feed Cylinder Structure: |

Multi-Room Feeding |

| Type: |

Isobar Filling |

| Composition: |

Filling Machine |

| Processing Material: |

Stainless Steel |

Product Description

CIP cleaning carbonated water filling line / machine / device precise Valve

Product description

Water Treatment

According to the customer requirements and the source water quality, we adopt different equipment to produce pure water, mineral water,etc. The main equipments are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator,water tank,etc. The treatment capacity is 0.5-50 ton/hour. It can effectively get rid of muddy organic matter, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of microorganism and some of heavy metal ion in the water, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water.

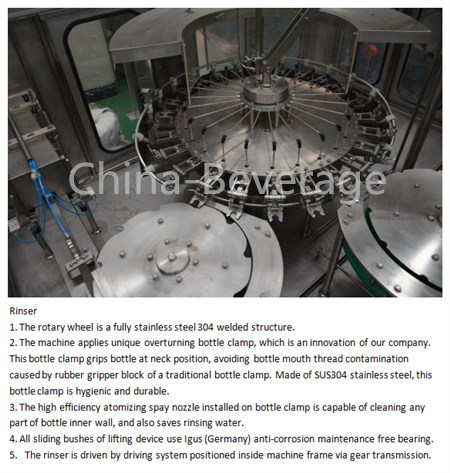

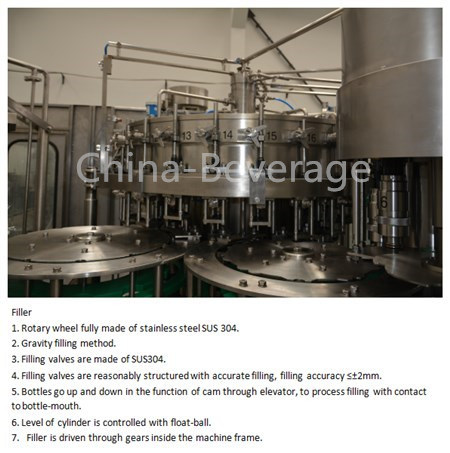

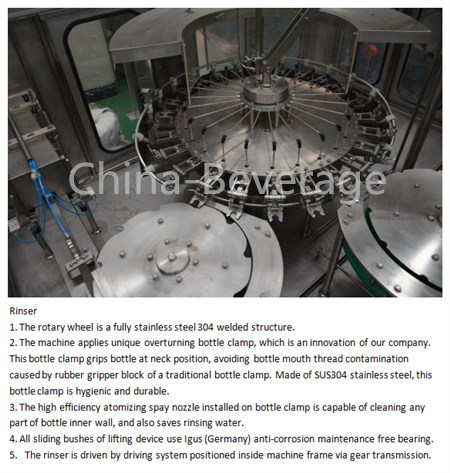

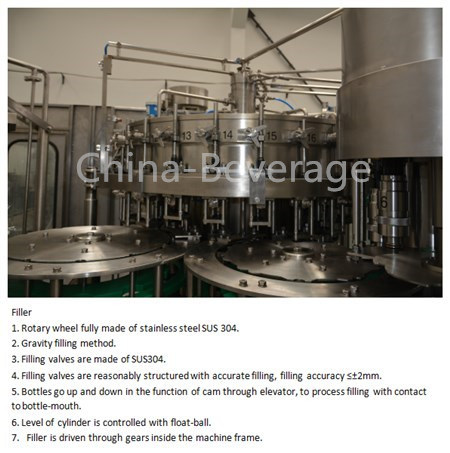

Washing, filling and capping 3-in-1 Machine

This machine is mainly applied for filling drinks. It combines rinsing bottle, filling and capping into one machine. The full procedure is automatics. It is suitable for PET bottle and plastic bottle to fill juice, mineral water, pure water, if add temperature control device, even for hot filling. The adjustment for bottle type of each unit is fulfilled by turning handle; it is simple, easy and quick. The filling method applies new micro pressure filling so that the filling speed becomes more quick and stable. Compared with similar machines, it has higher yield, more benefit. The machine applies advance OMRON programmable controller (PLC) to control machine's auto-running, the input bottle chain way changes its speed by frequency converter. Cooperate more stable and reliable. As each unit's running is detected by photoelectric elements. So it has high automation and simple operation. On this basis, changing filling unit can change to low vacuum filling method and isotonic filling method. Low vacuum filling method (Z type machine) is applied for glass bottle to fill alcoholic liquor; soy etc. and the capping method can be aluminum anti-theft cap and plastic cap. The isotonic filling method (D type machine) is applied for PET bottle; plastic bottle to fill CO2 contained drinks. It is the ideal top choice equipment of drinks enterprise.

Technical parameters

Model | DXGF 24-24-6 | DXGF 50-50-12 | DXGF 72-72-15 | DXGF 24-32-6 |

Capacity | 6000BPH (500ml) | 15000 BPH (500ml) | 21000 BPH (500ml) | 9000 BPH (500ml) |

Suitable bottle | Diameter 50-110 ; height 150-360 |

Air pressure | 0.7 MPa |

Gas consumption | 1m3/min |

Co2 consumption | 600g/hl |

Total power | 2.57 Kw | 5.5Kw | 7.5Kw | 4.5Kw |

Total size | 3290×2780×2800 mm | 5150×3820×2700 mm | 7228×5300×2750 mm | 4420×3255×2700 |

Total weight | 5000Kg | 10000Kg | 12000Kg | 6500kg |

Detail Images

Company infomation

Company infomation

Our Service Pre-service

1. Guiding customers to choose the most suitable machine and give our suggestion.

2. Provide the technical flow chart, machine photo, even machine vedio

3. Specially designed for customer.

4. Help customer design the workshop layout

On-sale service

1. Tell customer about the production from time to time

2. Do preparation for customer checking at any time.

3. Help customer clean goods

After-sale services

1. Oversea install an training

2. Free maintenance and replacements of spare parts for free in 12 months.

3. Provide technical support

Jiangsu Zhongyin Machinery Co., Ltd. is located in Donglai Town, Zhangjiagang City, Jiangsu Province. It has international standard workshop more than 15000 square meters. It is one of the professional beverage packaging machinery manufacturers with collecting research, development and manufacturing. It is China's best beverage machinery equipment suppliers. As liquid packaging industry enterprise, the drink service network is all over the world more than 30 countries and regions, products are widely used in drinks, flavor, cosmetic, beer, milk, and pharmaceutical industries.

Since company has begun, focused on the professional technology --- beverage packaging machinery, to forge leading beverage packaging machinery, upstream and downstream related both beverage packaging equipment research and development. Always adhere to technological innovation to drive the company development. It has been applied for patents, has formed a unique market with competitive advantage. In order to make our equipment performance better and more stable of operation, our company cooperates with domestic professional institutes, colleges and universities to carry out the combination of the filling machine and optimized the related equipment design, especially with Shanghai jiaotong university school of mechanical engineering. Using Shanghai jiaotong university, wuxi institute of food engineering technology and other universities' strong technology research and development strength, to analyze the foreign advanced technology, digestion on the basis of absorbing foreign advanced technology, to change our original design perfectly, and achieved good results.

Gathering the domestic famous machinery manufacturing enterprise, which have many years' staff more than 60 from machinery, technology and automatic control these 3 fields. It's the strong team of liquid (drink) packaging machinery industry in China, the existing 2 food engineering doctor, 5 masters, 12 senior engineers, can provide users with: Market positioning analysis, designing, engineer training and a set of turnkey solution project and related services. The strong research and development and the design team are the impulsion of enterprise development. Company aim at the world's most advanced beverage packaging machinery technology, introduced full beverage packaging machinery technology from Germany, Italy, France and Switzerland, adhering the fast introduction, more improvement and innovative ideas, to master the core technology and related technology, do a three-dimensional research and comprehensive development, developed a lot of original technology. At present, the company self-design and develop the small and medium-sized sterile line, including tube, intubation system has been applied for a utility model patent certificate, etc. Leading science and technology, continuously explore and practice, formed the company brilliant tomorrow.

Modern factory, all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, constitute the drink mechanical excellence in product manufacturing system. It also provides Zhongyin Machinery product's quality in the most powerful guarantee. With sophisticated manufacturing equipment and testing equipment to complete parts processing, in accordance with the ISO9001: 2000 standard certification system, production process of strict quality management, attention to every assembly detail, experienced technical personnel, for each key nodes in the process of equipment assembly for effective monitoring, to ensure that each product's performance and appearance are perfect as far as possible.