| Prod Model: |

OH7500 |

| AC Voltage Requirement: |

380V |

| Gas Capacity: |

7500L/H |

| Water Consumption: |

4L/H |

| Working Medium: |

Pure/Soft Water,Electricity |

| Dimension: |

1650*800*1500mm |

| Gross Weight: |

552kgs |

| Application: |

Welding,Metal Cutting,Hho Boiler Heating |

| Advantage: |

Eco-Friendly,Energy Saving,Precision Cutting |

| Water Feed: |

Automatic |

| Feature: |

Oxy-Hydrogen Flame Cutting, Automatic Cutting |

| Type: |

Plasma |

| Control Mode: |

CNC |

| Cutting Mode: |

Plasma |

| Gas: |

Oxygen and Hydrogen Gas |

Product Description

CNC plasma cutting oxyhydrogen gas cutting machine plasma cutterThe Technical Data

Larger industrial

Oxy Hydrogen gas generator

| Select from 5 models of gas generator according to the volumes of Oxygen & Hydrogen required.

A 3-phase, 4-wire AC 380V power supply is required. |

| Model | OH3000 | OH5500 | OH7500 | OH10000 | OH20000 | | Hydrogen volume | 2000L/h | 3600L/h | 5000L/h | 6600L/h | 13000L/h | | Oxygen volume | 1000L/h | 1800L/h | 2500L/h | 3300L/h | 6700L/h | | Continuous supply pressure | 0.20 MPa | | Electric power consumption | 9kwh | 17.5kwh | 23kwh | 31kwh | 70kwh | | Water consumption | 1.6L/h | 2.9L/h | 4L/h | 5.3L/h | 11.6L/h | | Dimension | 1070*670*1500mm | 1200*670*1700mm | 1650*800*1500mm | 1520*900*1490mm | 13000*1100*1800mm | | Weight | 300kg | 396kg | 552kg | 610kg | 610kg |

|

Products Description

Okay Energy oxyhydrogen gas generator is a low cost, high quality, clean cutting system.

The "Okay Energy" HHO hydrogen gas cutting system consists of a gas generator and a flame cutting machine.

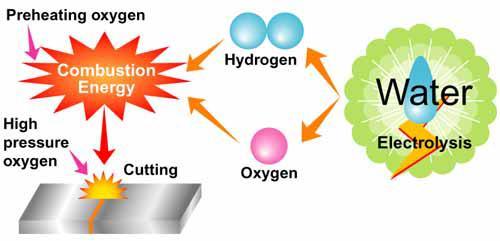

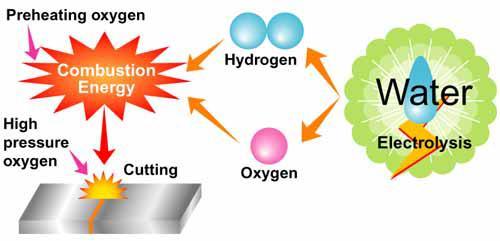

The gas generator generates Hydrogen and Oxygen from water by electrolysis.

This system features low operating costs and environmental benefits because of no emission of CO2 or poisonous gases. The gas generator can also be connected to conventional flame cutting machines.

Cutting video demo

videos machine demo for play :http://www.okayenergy.com/video/cutting-video/

widely used in Carbon Steel Cutting and continuous casting slab cutting of steel plant. It can be cooperate with manual cutting torch,semi-automatic cutting machine, shape cutting machine, CNC cutting machine to instead of traditional fuel gas.

Features and Advantages

Productivity Improvements

Machining time reduced by 20~30%

As the combustion rate of Hydrogen gas is faster than that of other fuel gases, the Hydrogen flame is narrower and more concentrated. This provides higher heat transfer rate, higher piercing speed and faster cutting. The shorter piercing time and increased cutting speed provides a significant cost saving when compared with LPG fuelled cutting.

Improved process quality Lower heat stress

The surface of cut edge is smooth and dross free, reducing or eliminating the secondary process should be changed to the surface of the cut edge is smooth and dross free, reducing or eliminating the need for secondary processing.

Installation easy and safety On-Site gas production

This system produces Hydrogen gas on site as required. Consequently there is no storage of high pressure gas required.The machine does not need any special installation or certified or skilled personnel for handling of compressed gas cylinders.

Safer fuel gas

Mixture of flammable gas and air or Oxygen is explosive, and it has a lower and upper limit of concentration for explosion.

Lower explosive limit for Propane gas = 2.2%

Lower explosive limit for Acetylene gas = 2.5%

Lower explosive limit for Hydrogen gas = 4.0%

Thus, Hydrogen is much safer than the other gases because of its higher value of Lower Explosive Limit. Additionally, because Hydrogen is lighter than air, it does not stagnate but will quickly diffuse in the atmosphere.

Environmentally friendly cutting CO2 Emissions reduction

Hydrogen is a clean energy source. Water is the only product of combustion. Hydrogen combustion produces no CO2 because the molecule contains no Carbon atom,Hydrogen is the cleanest energy as an alternative to LPG, Acetylene gas or Natural gas.

Wide Applications

Hydrogen gas cutting covers the same range of applications as conventional fossil fuel cutting with higher edge quality and accuracy.

Shipment and Package

About shipping We have long-term cooperated shipping counrier providing one-stop safety and quick shipping service.

Flexible Shipping method by international express(DHL,Fedex,UPS etc),by air,by sea as your requirement.Or using your shipping forwarder.

About Package Standard export package,1set/carton;For industrail larger machine,1set/woodern pallet;

Okay Service

1.24hour online chat,email or phone support for inquiry,technical and after-sales service;

2.Warranty:1year.(The core part of machine for 1year.The other parts of machine for half of year in addition to human damage;

3.online trade assurance service(Protection buyer's payment regarding on-time delivery and product quality.)

Company Introduction

Okay Energy Equipment Co.,Ltd is one of the largest manufacturers in producing oxyhydrogen generator for over 10 years, we have autorized CE,ISO9001,TUV,FCC certificates and our own patents.We provide the best service and high quality products to our customers. If you have any questions, pls don't be hesitate to contact us.

Okay Energy Equipment Co.Ltd

Adress:No.27,Wenxuan Road,Yuelu District,Changsha City,China

Tel: 0086-731-83979221

Web: www.okayenergy.com

Okay Energy Equipment Co., Ltd. is located in beautiful Changsha city, Hunan Province, China. Okay Energy Equipment Co., Ltd is a high-tech enterprise which focused on research, production and sales of oxy hydrogen generator, carbon clean machine, three-way catalytic converter carbon cleaning machine, oxyhydrogen welding machine etc. Oxy-hydrogen generator which transforms water into oxygen and hydrogen would lead a new energy revolution in 21st century.

There is a professional technology development team include professional doctor and technical personnel, production staff. Our production capacity is 500 units HHO hydrogen generator per month. All our products are produced with CE, FCC, SGS certification. Okay Energy owned 8 core technologies, 18 design and invention patents, over 30 products series.

We have passes ISO9001 system with independent production workshops including power supply, electrolytic cell production line and machine assemble line. Okay Energy's the 2ND factory plant will be put in production in 2018, and the yearly capacity is expected to 2 million units oxy-hydrogen generators.

Okay Energy 11 years development introduction:

1. Okay Energy founded on Oct 23th, 2006 (2006)

2.10 design & invention Patents of oxyhyrogen generator (2008)

3. The first manufacturer of HHO carbon cleaning machine in China (2009)

4. Wireless engine detection technology(2011)

5. Integrated forming electrolysis cell technology (2012)

6. PLC micro-computer control system (2013)

7. HD TFT screen (2014)

8. Touch screen(2015)

9. The first Chinese manufacturer produce 20000L/H HHO gas. (2015)

10. Mobile service machine for carbon cleaning (2016)

11. WiFi monitoring solution: Touch screen and mobile phone synchronization (2017)

12. Owing 18 design & invention patents, 7 core hho technology, over 30 series products now.

Okay Energy core technology including anti explosion and anti leakage integrated electrolytic tank, dry and wet combination anti back-fire flash arrestor, pre-anti backfire oxyhydrogen torch, PLC control panel technology, IGBT high efficiency power supply, stable pressure device, and okaycloud system. Our machines can be 24 hours continuous working and the main machine can run 5 -10 years.

We are always devoting to improve old products and develop new products, do our best to meet the market demand. Integrity is our promise and quality is goal. Welcome buyers from home and abroad to visit our company and win business together.