| Prod Model: |

mold-B |

| Shaping Mode: |

Injection Mould |

| Process Combination Type: |

Compound Die |

| Installation: |

Mobile |

Product Description

Customize Exported High precision mold -- Teconn

Dongguan Teconn Electronics Technology Co.,Ltd. was established in 2005, under Wenzhou Yihua Group(to be listed companies). 2010 was awarded the national high-tech enterprises.

The factory is located at the junction of Changan Xiabian and Humen Shutian in the 358 provincial highway, covering an area about 130 mu.There are 9 building with 6 layers staff dormitories which can accommodate 10000 people.

Teconn is expanding the molding, structural products and CNC products. | 1 | Mould Base | Hasco, DME ,TSMP,MSMOU ect ; |

| 2 | Cavity material | 45#,50#,2738,2343,DIN-1,S130,H13,2344,738H,718,8407,S136,NAK80,P20,KD-61,NIMAX ect |

| 3 | Steel hardness | 20-60HRC |

| 4 | Treatment | Pre-Harden, Nitriding, Heat treatment, Quenching |

| 5 | Cavity Qty | Single-cavity / Multi-cavity |

| 6 | Runner | Hot runner or Cold runner : MASTIP/ HASCO/ DME/ FISA/HUSKY/MOLD-MASTER/SYNVENTIRE/ANNTONG |

| 7 | Gate | Submarine gate, side/edge gate, direct gate ect |

| 8 | Plastic material | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE etc |

| 9 | Mould Life | 500K - 5millon shots at least |

| 10 | Design Software | UG, CAD, 3D MAX ,PRO-E, Solid Works etc, |

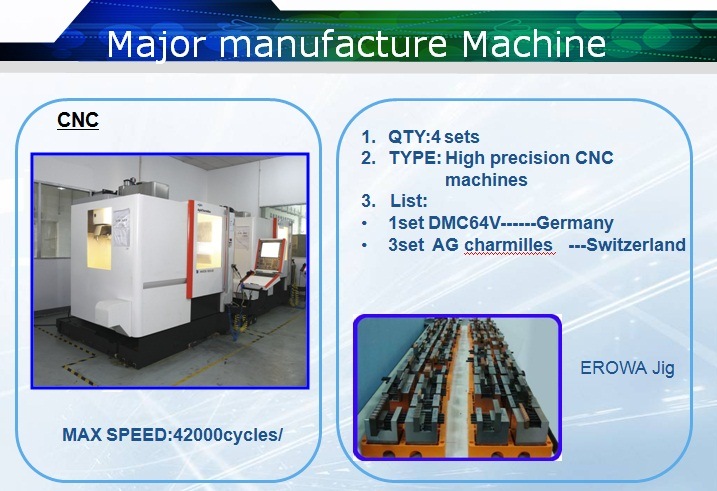

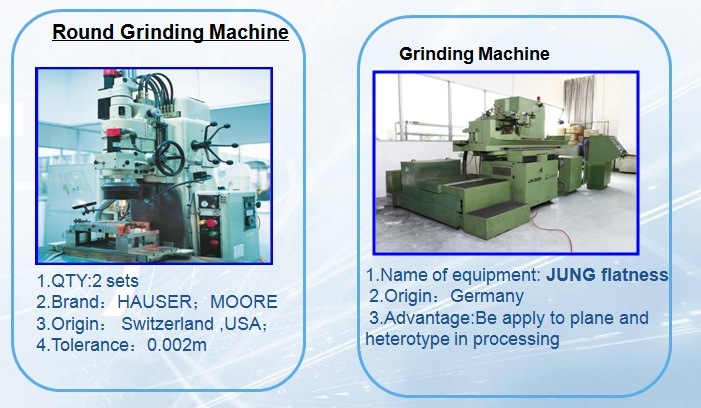

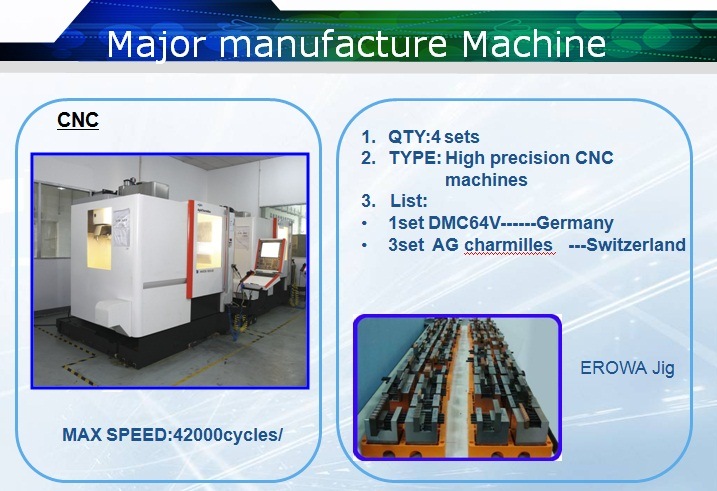

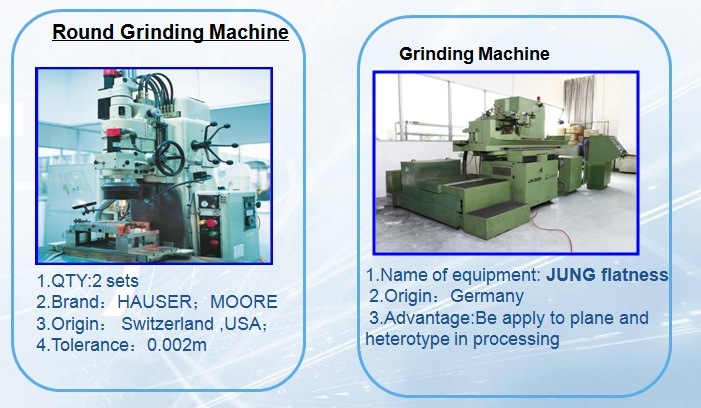

| 11 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish etc |

| 12 | Quality | ISO9001:2000 Certificate |

| 13 | Lead Time | 10-30 workdays depends on the different products |

| 14 | Package | Wooden Case Package or according to customer requirement |

| 15 | 10 years professional manufacture experience, We are specialize in design and manufacture of plastic injection mould ( tooling) for Automotive, Electrical appliances ,House wares ,Medical devices,, Communication industries and etc. |

Teconn Mold Workflow

a) RFQ from you (2D, 3D drawings, specifications, or samples)

b) Sales reply quotation within two- three working days.(some urgent would be within 24 hours is available)

c) 2D&3D design: within a week (after the PO authorized)

d) Weekly report to customers for following every Monday.

e) Engineers follow projects until to mold trails and get customers approval for shipment.

f) Ship moulds or products as customer required

g) Engineers and sales are responsible on all the issue after service for customers

Tool shop show

Tool shop show

Advantages

•Offer best price as reasonable as possible.

•Customer-oriented, thinking and doing by standing customers' side.

•Fully understanding of customers' requirements and provide one to one engineers service.

•Trying best to predict possible problems before starting projects.

•Tightly following, Timely response and Never find excuses when problems happen.

• Multi win-win for all of us related (suppliers--Teconn--customers).

Our Cutomers

Looking forward to the Multi win-win cooperation with you.Any plastic injection molding projects, please feel free to contact us at any time.

Looking forward to the Multi win-win cooperation with you.Any plastic injection molding projects, please feel free to contact us at any time.

Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.