| Prod Model: |

ES101 Series VFD for Injection Molding Machine |

| Certificates: |

ISO 9001-2008/Ts16949: 2009, Ce, RoHS |

| IGBT And DSP: |

Infineon and Taxas Instrument's Latest IGBT & DSP |

| Starting Torque: |

0.5Hz: 180% (V/F Control, SVC1); 0.25Hz: 180% (SVC |

| Control Technique: |

V/F, SVC1, SVC2 |

| Input Terminals: |

Di-7(HDI-1), Ai-3 0~10V, or 0-20mA |

| Output Terminals: |

Do-2(Hdo-1), RO-2, Ao-2 |

| Frequency Command Source: |

Keypad, Terminals, Communication |

| Speed Regulation Range: |

1:100 (V/F Control, SVC1); 1:200 (SVC2) |

| OEM Service: |

Available |

| Distributorship: |

Still Available in Some Countries |

| Application: |

High Frequency Converter Transducer |

| Output Type: |

Triple |

| Principle Of Work: |

Vector Control Transducer |

| Switch Mode: |

PWM Control |

| Main Circuit Type: |

Voltage |

| Brand: |

Gtake |

Product Description

ES101 Series VFD Drives for Injection Molding Machine

ES101 Series VFDs are cabinet-type drives, and hence can be located directly on the ground. The cabinet inside is equipped with mains frequency and variable frequency switch contactor. Working status of mains frequency and variable frequency can be manually switched by the key rotary switch on cabinet panel.

The cabinet inside is equipped with analog sampling interface card EPC-IM1 dedicated for injection molding machine.

| VFDs Model | Power Rating | Input Voltage | Output FREQ | Type |

| ES101 series | 11kW-75kW | 400V, ±10% | 0.00-600.00Hz | DC/AC to AC inverters |

ES101 Series VFDs model and technical data

| Model | Power Rating (kW) | Rated Output Current (A) | Rated Input

current (A) | Applicable motor (kW) |

| ES101-4T11B | 11 | 24 | 29 | 11 |

| ES101-4T15B | 15 | 30 | 35 | 15 |

| ES101-4T18.5 | 18.5 | 39 | 44 | 18.5 |

| ES101-4T18.5B | 18.5 | 39 | 44 | 18.5 |

| ES101-4T22 | 22 | 45 | 50 | 22 |

| ES101-4T22B | 22 | 45 | 50 | 22 |

| ES101-4T30 | 30 | 60 | 65 | 30 |

| ES101-4T30B | 30 | 60 | 65 | 30 |

| ES101-4T37 | 37 | 75 | 80 | 37 |

| ES101-4T37B | 37 | 75 | 80 | 37 |

| ES101-4T45 | 45 | 91 | 95 | 45 |

| ES101-4T45B | 45 | 91 | 95 | 45 |

| ES101-4T55 | 55 | 112 | 118 | 55 |

| ES101-4T55B | 55 | 112 | 118 | 55 |

| ES101-4T75 | 75 | 150 | 157 | 75 |

| ES101-4T75B | 75 | 150 | 157 | 75 |

Technical Features of ES101 VFD

Technical features| Power input | Rated input voltage | 3-phase AC208V/AC220V/AC230V/AC240V/AC380V/

AC400V/AC415V/AC440V/AC460V/AC480V |

| Rated input current | See Section 2.3 |

| Frequency | 50Hz/60Hz, tolerance ±5% |

| Allowable range of voltage | Continuous voltage fluctuation ±10%,

short fluctuation -15%~+10%, i.e. 323V~528V; |

Voltage out-of-balance rate <3%,

distortion rate as per the requirements of IEC61800-2 |

| Power output | Applicable motor (kW) | See Section 2.3 |

| Rated current (A) | See Section 2.3 |

| Output voltage (V) | 3-phase: 0~ rated input voltage, error < ±3% |

| Output frequency (Hz) | 0.00~ 600.00Hz; unit: 0.01Hz |

| Overload capacity | 150% - 1min; 180% - 10s; 200% - 0.5s |

| Control characteristics | V/f patterns | V/f control |

| Sensor-less vector control 1 |

| Sensor-less vector control 2 |

| Close-loop vector control |

| Speed range | 1:100 (V/f control, sensor-less vector control 1) |

| 1:200 (sensor-less vector control 2) |

| 1:1000 (close-loop vector control) |

| Speed accuracy | ±0.5% (V/f control) |

| ±0.2% (sensor-less vector control 1 & 2) |

| ±0.02% (close-loop vector control) |

| Speed fluctuation | ±0.3% (sensor-less vector control 1 & 2) |

| ±0.1% (close-loop vector control) |

| Torque response | < 10ms (sensor-less vector control 1 & 2) |

| < 5ms (close-loop vector control) |

| Torque control accuracy | ±7.5% (sensor-less vector control 2) |

| ±5% (close-loop vector control) |

| Starting torque | 0.5Hz: 180% (V/f control, sensor-less vector control 1) |

| 0.25Hz: 180% (sensor-less vector control 2) |

| 0Hz: 200% (close-loop vector control) |

| Basic functions | Start frequency | 0.00~ 600.00Hz |

| Accel/Decel time | 0.00~60000s | |

| |

| Carrier frequency | 0.7kHz~16kHz |

| Frequency command sources | Digital setting + keypad ∧/∨ |

| Digital setting + terminal UP/DOWN |

| Communication |

| Analog setting (AI1/AI2/AI3) |

| Terminal pulse setting |

| Motor started methods | Started from starting frequency |

| DC brake then started |

| Speed search started |

| Motor stopped methods | Ramp to stop |

| Coast to stop |

| Ramp to stop + DC brake |

| Basic functions | Dynamic brake capacity | Brake unit threshold voltage: 650V~750V; service time: 0.0~100.0s; |

| DC brake capacity | DC brake start frequency: 0.00~600.00Hz |

| DC brake current: 0.0~100.0% |

| DC brake time: 0.0~30.00s |

| Input terminals | 7 digital inputs, one of which can be used for high-speed pulse input. Compatible with active open collectors NPN, PNP and dry contact input. |

| 3 analog inputs, one of which supports voltage input only, and the other two are voltage/current programmable. |

| Output terminals | One high-speed pulse output terminal, 0~50kHz square signal; can output command frequency, output frequency and so forth |

| One digital output terminal |

| Two relay output terminals |

| Two analog output terminal, voltage/current programmable; can output command frequency, output frequency and so forth |

| Encoder signal terminal | Compatible with 5V/12V encoder |

| Compatible with different types of encoder signal input, such as open collector, push-pull and differential, etc. |

| Protection function | Refer to the User Manual Chapter 7 - Troubleshooting |

| Environment | Place of operation | Indoors, no direct sunlight, free from dust, corrosive gases, flammable gases, oil mist, water vapor, water drop and salt, etc. | |

| |

| Altitude | 0~2000m De-rate 1% for every 100m when the altitude is above 1000 meters |

| Ambient temperature | -10ºC~40ºC

De-rated 1% for every 1ºC if between 40ºC~50ºC | |

| |

| Relative humidity | 5~95%, no condensation |

| Vibration | Less than 5.9m/s2 (0.6g) |

| Storage temperature | -40ºC~+70ºC |

| Others | Efficiency at rated Amps | 11~ 45kW: ≥ 95%

55kW~75kw: ≥98% | |

| |

| Installation | Cabinet |

| IP grade | IP20 |

| Cooling method | Fan cooled |

Control Terminal Specification| Category | Terminal | Terminal designation | Specification |

| Analog input | +10V | Analog input reference voltage | 10.3V ±3% |

| Maximum output current 25mA |

| The resistance of external potentiometer should be larger than 400Ω |

| GND | Analog ground | Isolated from COM interiorly |

| AI1 | Analog input 1 | 0~20mA: input impedance - 500Ω, maximum input current - 25mA |

| 0~10V: input impedance - 22kΩ, maximum input voltage - 12.5V |

| Switch S2 on control board for jumping from 0~20mA and 0~10V, factory default: 0~10V |

| AI2 | Analog input 2 | 0~20mA: input impedance: 500Ω, maximum input current: 25mA |

| 0~10V: input impedance: 22kΩ, maximum input voltage: 12.5V |

| Switch S3 on control board for jumping from 0~20mA and 0~10V, factory default: 0~10V |

| Toggle switch S4 can realize analog input of direct detection of motor temperature |

| AI3 | Analog input 3 | -10V~10V: input impedance: 25 kΩ |

| Maximum range of input voltage: -12.5V~+12.5V |

| Analog output | AO1 | Analog output 1 | 0~20mA: impedance: 200Ω~500Ω |

| 0~10V: impedance ≥ 10k |

| Switch S5 on control board for jumping from 0~20mA and 0~10V, factory default: 0~10V |

| AO2 | Analog output 2 | 0~20mA: impedance: 200Ω~500Ω |

| 0~10V: impedance: ≥10kΩ |

| Switch S6 on control board for jumping from 0~20mA and 0~10V, factory default: 0~10V |

| GND | Analog ground | Isolated from COM interiorly |

| Digital input | +24V | +24V | 24V±10%, Isolated from GND interiorly |

| Maximum load: 200mA |

| PLC | Digital input Common terminal | Used for switching between high and low levels, short-circuited with +24V at delivery, i.e. low value of digital input valid |

| External power input |

| COM | +24V ground | Isolated from GND interiorly |

| X1~X6 | Digital input Terminals 1~6 | Input: 24VDC, 5mA |

| Range of frequency: 0~200Hz |

| Range of voltage: 10V~30V |

| X7/DI | Digital input/pulse input | Digital input: same as X1~X6 |

| Pulse input: 0.1Hz~50kHz; range of voltage: 10-30V |

| Digital output | Y1 | Open collector output | Range of voltage: 0~24V |

| Range of current: 0~50mA |

| Y2/DO | Open collector output/Pulse output | Open collector output: same as Y1 |

| Pulse output: 0~50kHz; |

| Relay 1 output | RA/RB/RC | Relay output | RA-RB: NC |

| RA-RC: NO |

| Contact capacity: 250VAC/3A, 30VDC/3A |

| Relay 2 output | TA/TB/TC | Relay output | TA-TB: NC |

| TA-TC: NO |

| Contact capacity: 250VAC/3A, 30VDC/3A |

| Encoder signal input | VCC | Encoder power supply | Select power supply 5V/12V for encoder by S7 |

| COM | Encoder power ground | Isolated from GND interiorly |

| A+ | Phase input A+ | Select differential/OC input mode by S7. |

| In OC mode, this terminal is not connected |

| A- | Phase input A- | Select differential/OC input mode by S7. |

| In OC mode, this terminal is directly connected to phase A signal of the encoder |

| B+ | Phase input B+ | Select differential/OC input mode by S7. |

| In OC mode, this terminal is not connected |

| B- | Phase input B- | Select differential/OC input mode by S7 |

| In OC mode, this terminal is directly connected to phase B signal of the encoder |

| Terminal 485 Interface | 485+ | Differential signal 485+ | Rate:4800/9600/19200/38400/57600/115200bps |

| 485− | Differential signal 485- | Maximum distance: 500m (use standard network cable) |

| GND | 485 Communication shielded ground | Isolated from COM interiorly |

| Keypad 485 interface | CN4 | Keypad 485 interface | Use standard network cable |

| Maximum cable distance: 15m |

+ Advantages of GTAKE AC drives

Thanks to sophisticated engineers, scientific producing workmanship, rigorous quality control systems and management team, GTAKE frequency inverters are equipped with advanced features, some of which are listed as below:

01 Starting torque: 180%,0.25Hz (sensor-less vector control 2), 150%,0.5Hz (sensor-less vector control 1);

02 Speed adjustable range: 0-50Hz: 1:200 (sensor-less vector control 2), 1:100 (V/Hz control, sensor-less

vector control 1);

03 Speed accuracy: +/-0.2% (sensor-less vector control 1&2), +/-0.5% (V/Hz control);

04 Speed fluctuation: +/-0.3% (sensor-less vector control 1&2);

05 Torque response: less than 10ms (sensor-less vector control 1&2);

06 Over load capability: 150% 1minute, 180% 10 seconds, 200% 0.5 second, once every 10 minutes;

07 Output frequency: 0.00-600.00Hz, or customized like 1MHz;

08 Abundant frequency setting sources;

09 DC brake start frequency: any frequency in the range of 0Hz to 600.00Hz;

10 Diverse input and output terminals;

11 Ambient temperature: -10°C~50°C;

12 High precise torque limit, process PID control, simple PLC, wobble frequency control, mechanical

brake control, field weakening control, all-side protection, etc.

13 Online and offline auto-tuning both available;

14 Extreme short-time acceleration can be operated without trip, such as 0.1s from 0Hz to 50Hz. + Why choose GTAKE variable frequency drive?

In the trend of advocating smart and simple industrial automation, environmentally friendly products, value-added solutions, Gtake, as one of the world's leading drive manufacturers aggressively investing in R&D, production, and continuous quality improvement, is well positioned to provide its customers with technology-driven, performance-outstanding products such as VFDs, wind power converters, servo drives, HEV/EV drives, helping its customers save energy and increase industrial productivity with sustainability on the one hand, and enhancing their entire value-chain quality, delivery, and services on the other hand.

- GTAKE VS Other brands | Performance | Common brands | GTAKE |

| Applicable motors | asynchronous motors | asynchronous motors |

| synchronous motors |

| Starting torque | 2.0Hz, 150% (sensor-less vector control) | 0.5Hz, 180% (sensor-less vector control) |

| 0Hz, 180% (closed-loop vector control) | 0Hz, 200% (closed-loop vector control) |

| Speed adjustable range | 1:100 (SVC), 1:1000 (VC) | 1:200 (SVC), 1:1000 (VC) |

| Ambient temperature (no derating required) | -10-40ºC | -10-50ºC (for most of the models) |

| Rated input voltage | 208VAC-400VAC | 208VAC-480VAC |

| Communication | Modbus RTU//ASCII | Modbus RTU//ASCII |

| Profibus-DP, CANope, etc. |

| Position control (fixed length, or angular positioning) | X | √ |

| Field weakening control | X | √ |

| Autotune | online | online |

| X | offline |

| Short-time ramp-up | trip | no trip |

| Customized features (software and/or hardware) | unprocurable or no experience | procurable with rich experience |

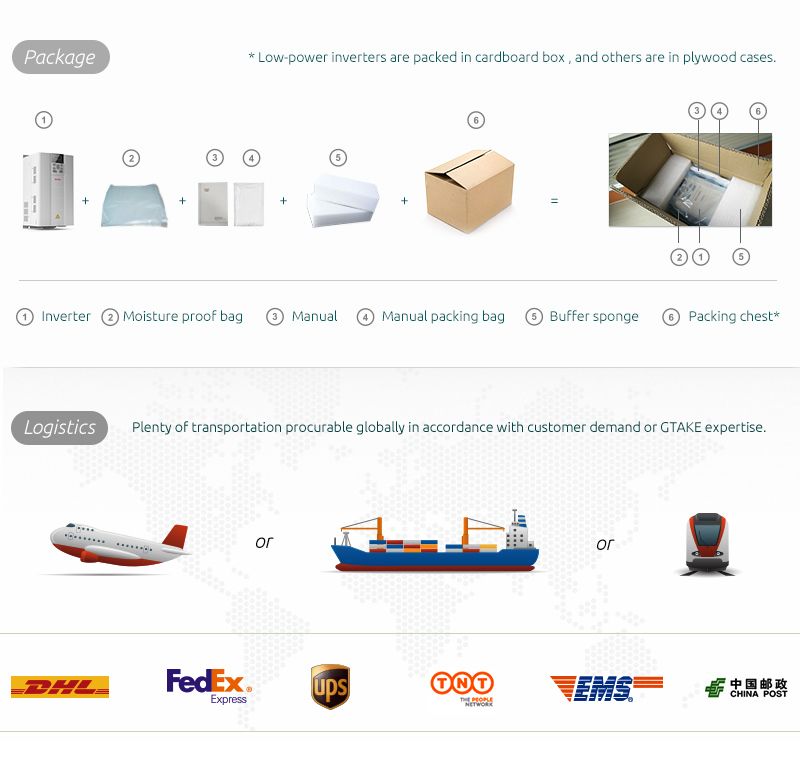

- Packaging and logistics

All drives are well packed before shipment, fit for air shipment, sea transportation, and express delivery. Customers are able to call its own nominated forwarder or consult GTAKE logistics department for worldwide shipment services.

GTAKE Drives Main Overseas Markets: Our frequency inverters are mainly exported to Russia, Turkey, UAE, Pakistan, Bangladesh, India, Sweden, Vietnam, Thailand, Malaysia, Indonesia, Iran, Egypt, South Africa, USA, and Brazil.

Please leave us an inquiry for more details of our frequency inverters, like information of the model numbers, technical data, applicable application, pricing, distributor policy, lead time and/or customized functionality.

Jiangsu Gtake Electric Co., Ltd. Was established in 2009. Innovation and keeping on innovating is the core value of Gtake. On the basis of our proprietary intellectual property rights, bearing power electronics technology and motor control technology, Gtake is committed to building the best world-class product and technology platform of China with the purpose of serving middle and high-end customers at home and abroad, using industry-leading product and system solutions.

Gtake focuses on the development of such renewable energy products as industrial frequency inverter, servo drive, PV inverter, hybrid vehicle drive, and wind power generation converter, etc.

Gtake will continue to spare no efforts to reinforce the position as a product, technology and market leader and optimize the efficient management, high profitability and other clear competitive advantages as a leading brand to become a standard bearer for national industry. Gtake always contributes efforts to help our customers improve production efficiency, save energy consumption and fulfill social responsibilities.