| Prod Model: |

GV-mold |

| Mold Life: |

300000 to 1000000 Shots |

| Shaping Mode: |

Injection Mould |

| Process Combination Type: |

Single-Process Mode |

| Application: |

Home Use |

| Installation: |

Fixed |

| Mould Cavity: |

Single / Multi |

Product Description

Factory Direct Unique Design Plastic Mould for Home Application

Description:| Plastic product injection mold making for home appliances |

Mold Name | China mold product |

| Mold Shaping | China customized injection mold |

| De-mold Type | Automimatic Eject |

| Mold Base | LKM & Hasco & DME for choice |

| Mold Material | NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, etc |

| Mould Cavity | Singe or multias your requirement |

| Sprue Gate | YUDO runner, Hot runner, Cold runner, Pin -point gate, Submarine gate,etc |

| Design Software | UG, PROE, CAD, CAXA, etc |

| Plastic Material | PP, PC, PS, PAG, POM, PE, PU, PVC, ABS, PMMA, etc |

| Mold Life | 300000-1000000 shots |

| Delivery Time | 20-40 days depends on mold |

| Payment Terms | T/T, Paypal etc |

| Packaging | Wooden Cases |

| Transportation | By sea or by air as your requirement |

| Expor Country | worldwide |

| Specification | As your requirement |

| OEM /ODM Order | Welcome |

Company Profile:

Green Vitality Industry CO., Limited was founded in 1993, as starting from CNC processing in a small tooling building in Chang'an town, with more than 20 years experience in custom tooling and injection molding, nowadays we have become one of the global famous mold makers in manufacturing large plastic injection molds. We are full of capabilities and have great confidence in offering you professional one-stop solution of mold designing, mold making, injection molding and beyond-value service.

Factory Profile

6000 square meters mold making workshop, 8,000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

Factory Capability

40 molds per month

Max. mold size 3200x2200mm, Max. mold weight 25 tons

Advantage

Good quality mold and plastic parts

Reliable service

Our Service:

1. Supply both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly and other services

3. With more than 24 years experience, all of works are done 100% in our factory.

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept OEM / ODM / Customer Projects.

6. Mold building lead time: Around 40 days, with 1st Mold trialing report and Mold trailing samples

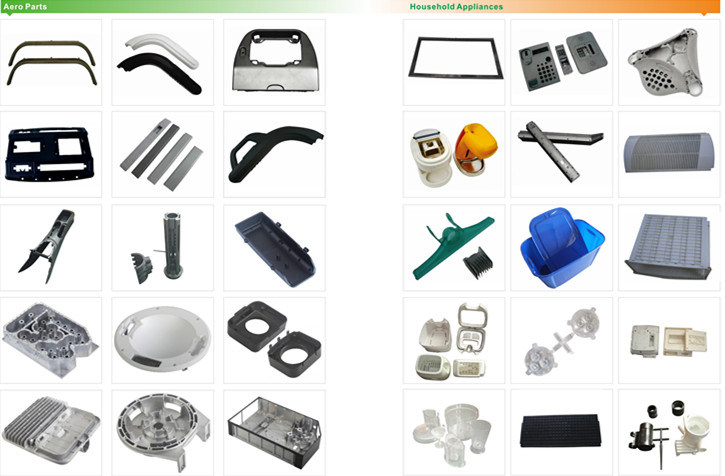

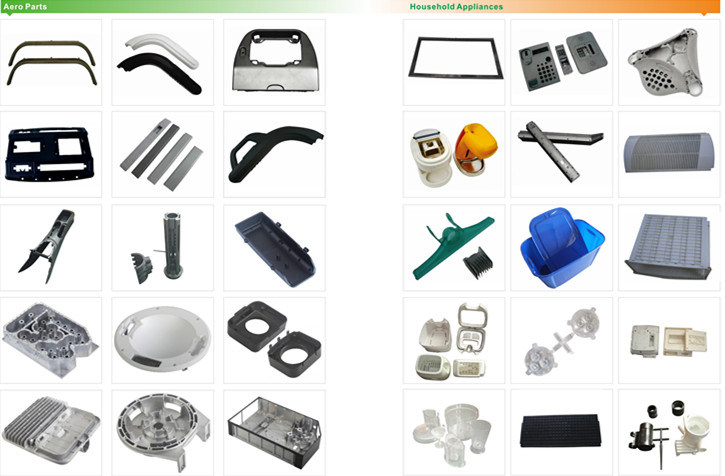

| Product Scope |

| Automobile | Auto interior plastic case, auto inner parts, bumper, door plate, auto lamp, instrument panel, auto connectors , electrical switch; car gear, complete sets of motorcycle parts; |

| Electronic | Wireless receiver plastic part, 3G/4G modem wireless network cards, USB connector, USB housing, remote control, key-press; |

| Mechanical | Motor support plastic part, pump plastic part, mower plastic parts; |

| Household | Colorful toys, fashion cup, juice cup, some small plastic parts; |

| Home appliance | such as TV front cover, TV rear cover, display cover, Air-conditioner or refrigerators plastic parts, washing machine part. |

| Medical | Hollow fiber dialyzer, deaf-Aid parts, medical instrument body plastic parts, blood-pressure meter (parts), Stapler. |

Process:

1. Quote: According to sample, drawing and specific requirement.

2. Discussion: Mold material, cavity number, price, runner, payment, etc.

3. S/C Signature: Approval for all the items

4. Advance: Pay 30% by T/T

5. Product Design Checking: If some position is not perfect, we will send customer the report.

6. Mould Design: We will communicate&Exchange the opinion with you during making drawing.

7. Mold Tooling: We start to make mold after mold design confirmed

8. Mold Processing: Send report to customer once each week

9. Mold Testing: Send trial samples and try-out report to customer for confirmation

10. Mold Modification: According to customer's feedback

11. Balance settlement: 70% by T/T after the customer approved the trial sample and mould quality.

12. Delivery: By sea or air. The forwarder can be designated by your side.

We will help to reduce cost, improve competition and make your work easier.

Any further inquiry or requirement, just feel free to contact us below.

Thank you so much!

Green Vitality Industry Co., Limited was founded in 1993, as starting from CNC processing in a

Small tooling building in Chang'an town, with more than 20 years experience in custom tooling

And injection molding, nowadays we have become one of the global famous mold makers in

Manufacturing large plastic injection molds. With the modern business management system and

ISO9001: 2008 Quality System guideline, the sophisticated production techniques, the advanced

Manufacturing equipment, and our qualified and dedicated team, we are full of capabilities and

Have great confidence in offering you professional one-stop solution of mold designing, mold

Making, injection molding and beyond-value service. We serve a broad range of customers in the

Field of Auto Parts, Aero parts, Household Appliance, Industrial and Beauty. Green Vitality make

Over 400 molds per year, mainly of the molds and plastic parts are exported to America, Germany,

France, Turkey, Italy and other countries worldwide. We have established long-term cooperation

With our clients and are continually improve top quality molds and plastic parts to our clients,

Establishing close strategic partnership to keep customer's satisfaction and success, growing up

Together with customers.

Factory Profile

6000 square meters mold making workshop, 8, 000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

Factory Capability:

40 molds per month (Max. )

Max. Mold size 3200X2200mm, Max. Mold weight 25 tons

Service Scope:

Expert in Auto Parts, Aero parts and Household Appliance large plastic molds

Plastic parts injection

Prototype parts

Market Advantage:

Top quality mold and plastic parts

Reliable service