Product Feature

Product Feature

All size, intelligent control, strong power, microcomputer control;

Rotary heating rod, intelligent control, strong power, microcomputer control;

Induction bearing heater is an advanced, fast and controllable heating tool, which is safer and more environmental way of heating.Technical ParametersPower supply: 2.5-12 KVA

Voltage :220, 380V

Rated current: 10-32A

Min. inner diameter of workpiece: 15-60m

Max. outside diameter of workpiece: 220-1020mm

Max. width of workpiece: 95-380mm

Stainless steel induction heater

Bearing heater/induction heater device

1. Improve assembly quality, even heating, high precision, keep surface harness constant;

2. Improve work efficiency, quick heating speed, reduce works strength, improve assembly progress, reach to the aim of civilized production;

3. Rational and advanced in structure, easy, safe, reliable to operate with fire danger;

4. Save energy sources, reduce cost, improve profit, saving 100% oil compared with oil induction heating, save 60% oil compared with electric furnace;

5. After stopping heating, ZBJ series induction heater will automatically demagnetize below 0.8mt, which conforms to ZJS-004 standard. So it is the best induction heater equipment for civilized production, high-efficiency production and safe production.Model | SV24T10S | SV24T15S | SV24T20S | SV24T25S |

Power Supply (KVA) | 2.5 | 3.6 | 10 | 12 |

Rated Voltage (V) | 220 | 22/380 | 380 | 380 |

Rated Current (A) | 10 | 16 | 25 | 32 |

Frequency (Hz) | 50 | 50 | 50 | 50 |

Rocker Arm Design | -- | -- | √ | √ |

Magnetic Section (mm) | 40*40 | 45*45 | 65*65 | 85*85 |

Max. Weight of Workpiece (kg) | 15 | 50 | 150 | 600 |

Min. Inner Diameter of Workpiece (mm) | 15 | 20 | 45 | 60 |

Max. Outside Diameter of Workpiece (mm) | 220 | 480 | 720 | 1020 |

Max. Width of Workpiece (mm) | 95 | 175 | 200 | 380 |

Temperature Control | √ | √ | √ | √ |

Temperature Range (ºC) | 40-250 | 40-250 | 40-250 | 40-250 |

Magnetic Temperature Feeler | √ | √ | √ | √ |

Digital Display | √ | √ | √ | √ |

Time Setting | √ | √ | √ | √ |

Longest Time(minute) | 0-99 | 0-99 | 0-99 | 0-99 |

Sound Remind | √ | √ | √ | √ |

Error Warning | √ | √ | √ | √ |

Automatic Heat Preservation | √ | √ | √ | √ |

Demagnetization | Manual/Auto | Manual/Auto | Manual/Auto | Manual/Auto |

Heating Rod | 10, 14, 20, 30, 40 | 14, 20, 30, 45 | 30, 40, 50, 65 | 40, 60, 85 |

Extending Rod | Customized | Customized | Customized | Customized |

Warranty(Year) | 1 | 1 | 1 | 1 |

Dimension (mm) | 260*240*260 | 510*300*290 | 675*520*580 | 1600*850*1250 |

Weight(kg) | 15 | 35 | 84 | 250 |

Competitive Advantages1. High quality in competitive price;

2. Low minimun order quantity;

3. Wide range of products for your reference;

4. Good customer service: customer satisfaction is our promary goal. Prompt, professional service offered by passionate and patient international salespeople;

5. OEM services: customer's LOGO engraving, customized packaging, and produce the products according to customers' design, etc.Packaging Details1. Outside packaging: standard export wooden packing;

2. Inner packaging: stretch Film;

3. Customized packaging acceptable. Company Information

Company Information

Jiangsu Feiyao Machinery Manufacturing Co., Ltd. is a professional hydraulic tools manufacturer with 30-year experience in the design, production, sale and service of Hydraulic Products, Electrical Control Equipment and Mechanical Devices.

Jiangsu Feiyao has been in hydraulic tools industry since 1978. Mainly export:

Hydraulic cylinder jacks (5-1500ton), single double acting, hollow plunger; low height, lock nut;

Hydraulic torque wrenches(100-72000Nm);

PLC synchronous lifting system;

Hydraulic lifting pumps, manual and electric type;

Hydraulic pullers, manual and hydraulic type;

Hydraulic bolt tensioners;

Hydraulic flange spreader, manual and hydraulic type;

Hydraulic steel wire rope press machine

Hydraulic accessories(hoses, couplers, oil distributors, etc.)

Over the years we have grown into a diversified market based that now services customers all over the world. We enjoy listening to our customers needs and ideas while working hard to provide the best service and delivering the highest quality of parts.

We believe "service" is our number one customer. We hope our commitment to provide our customers quickly and efficiently with competitive prices will keep you coming back.

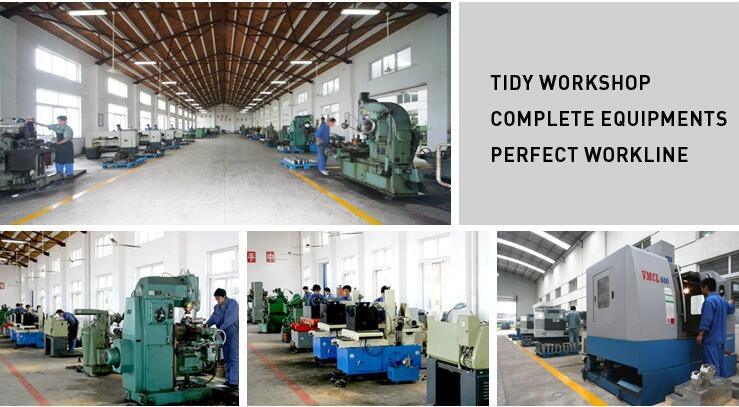

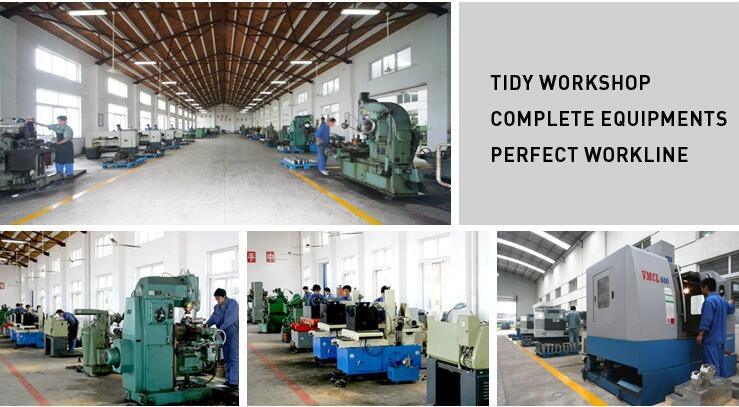

Factory Show

FAQ

Q1: How to contact sales?

A1: Please email or call: +86-180-3679-7771 for pre-sales.

Q2: How to make payment?

A2: Once order confirmed, we will prepare proforma invoice with our banking details.

Q3: How long does it take to process orders?

A3: It usually takes 10-14 business days to process most orders for no stock. If stock available, it only takes 2-3 business days.

Q4: What is the packing method?

A4: For small piece, we use carton box; for big piece, we use exporting grade plywood case.

Q5: How to ship?

A5: Sea freight, Air freight or International express(DHL, FEDEX,UPS...) all are available.

Q6: What is the warranty?

A6: 12 months against B/L date.

Contact Us: