Home Toolbuy Products High Chrome Grinding Media Steel Ball for Mining & Cement & Coal-Fired Power Plant & AAC Plant

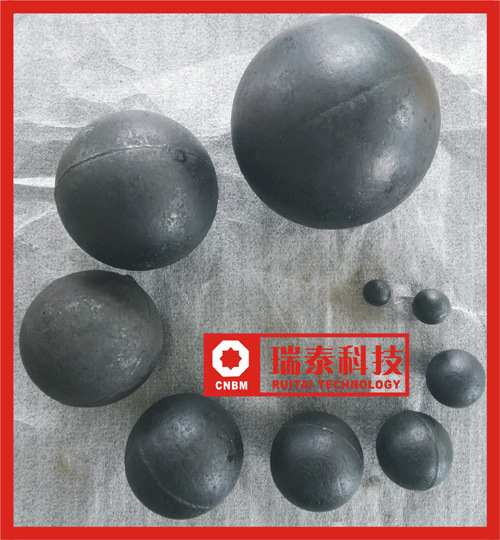

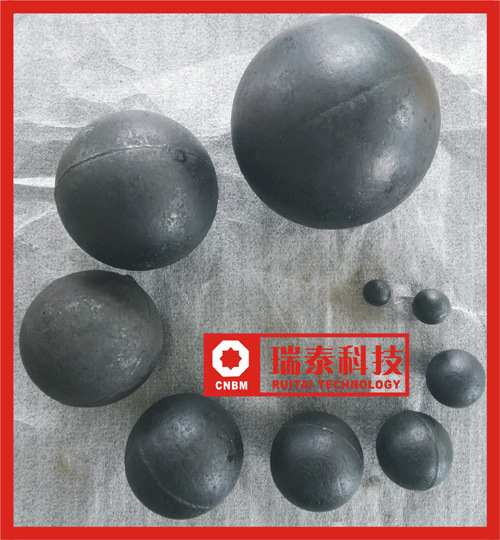

High Chrome Grinding Media Steel Ball for Mining & Cement & Coal-Fired Power Plant & AAC Plant

| Price: |

US $ 550-1300/Ton |

| Min Order: |

25/Ton |

| Pay Type: |

L/C,T/T,D/P |

| Prod Model: |

RT-B-HCr-2 |

| Material: |

Fe: 70% - 95% |

| Content: |

Cr: 1% -23% |

| Processing Type: |

Casting |

| Size: |

Dia 8-130 mm |

Product Description

High Chrome grinding media stee ball 1. Used to :Mining ore preparation, Cement Ball Mill, Coal-fired power plant, AAC plant, etc

2. Diameter:

2. Diameter: | Φ 8 mm | Φ10 mm | Φ12.5 mm | Φ15 mm | Φ17 mm | Φ20 mm |

| Φ25 mm | Φ30 mm | Φ40 mm | Φ50 mm | Φ60 mm | Φ70 mm |

| Φ80 mm | Φ90 mm | Φ100 mm | Φ110 mm | Φ120 mm | Φ130 mm |

3. THECHNICAL PARAMETERS

3. THECHNICAL PARAMETERS Product

Name | Product

Item | Chemical COmposition (%) |

| C | Si | Mn | Cr | S | P | Others |

| Low Cr | ZQCr1 | 1.8-3.2 | 0.3-1.0 | 0.2-1.0 | 1.0-3.0 | ≤0.15 | ≤0.25 | Trace |

| Middle | ZQCr5 | 1.8-3.2 | 0.3-1.0 | 0.2-1.0 | 4.0-6.0 | ≤0.10 | ≤0.12 | Trace |

| Chromium | ZQCr8 | 1.8-3.2 | 0.3-1.0 | 0.2-1.0 | 7.0-9.0 | ≤0.10 | ≤0.12 | Trace |

| | ZQCr10 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 10-12 | ≤0.10 | ≤0.10 | Trace |

| High | ZQCr15 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 14-16 | ≤0.10 | ≤0.10 | Trace |

| Chromium | ZQCr17 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 16-18 | ≤0.10 | ≤0.10 | Trace |

| Ball | ZQCr20 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 18-21 | ≤0.10 | ≤0.10 | Trace |

| | ZQCr23 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 21-24 | ≤0.10 | ≤0.10 | Trace |

| | ZQCr26 | 1.8-3.2 | 0.3-1.2 | 0.2-1.0 | 24-30 | ≤0.10 | ≤0.10 | Trace |

Products

Name | ITEM | Hardness

(HRC) | A K

(J/cm2) | Micro

Structure | Fall ball

Test (time) |

| High Cr ball | ZQCr10 | ≥58 | ≥3.5 | M+C+A | ≥20000 |

| Middle Cr ball | ZQCr5 | ≥47 | ≥2.0 | P+C | ≥12000 |

| Low Cr ball | ZQCr1 | ≥45 | ≥1.6 | P+C | ≥8000 |

| M - Martensite P - Pearlit C - Carbide A - Residual Austenitic |

4. PACKAGE: 0.8-1.0 mt per one Drums METAL DRUMS AND WOOD PALLETS, TWO DRUMS ON ONE PALLET or 1.0 mt per one nylon bag, without Wood pallets 4. BREAKAGE AND DESHAPING REPLACEMENT GUARANTEE 0 to 1% : no claim;1% to 3%: Replacement of broken balls; Over 3%: Replacement of tonnage supplied in the size where the occurs 5. ORDER MOQ:

4. BREAKAGE AND DESHAPING REPLACEMENT GUARANTEE 0 to 1% : no claim;1% to 3%: Replacement of broken balls; Over 3%: Replacement of tonnage supplied in the size where the occurs 5. ORDER MOQ:

100 MTs. (4 containers for one one shipment) 6. PAYMENT TERM: 1.

30% DEPOSIT, 70% T/T before shipment or (by Irrevocable L/C at sight); 2. Trial order (MOQ: 25 mts per one order) , 100% T/T before shipment 7. SHIPMENT: 15-30 days after get Deposit 8. Contact: Mr. James Wu

Mr. Star Wang

Anhui Ruitai new materials technology Co., Ltd (Anhui Ruitai) was founded in 2008, Located in Ningguo City, Anhui Province, nearby Shanghai. Anhui Ruitai is a certified ISO9001 / ISO14001 / OHSAA18001 Company, the professional manufacturer for Grinding ball and refractory material.

Anhui Ruitai is a subcompany of Beijing Ruitai Technology Group (Ruitai Technology, www. BJruitai. COM). Rutai Technology listed on China Shenzhen Stock Exchange (stock number: 002066), is one of the largest manufacturers for refractory material and grinding media in China.

Ruitai Technology is a number of CNBM group ( China National Building Material Group Corporation, www. Cnbm. COM. Cn), CNBM group is the No. 259 of Fortune Global 500 in 2017, its operating revenue of 39.3 billion USD. CNBM group is one of the largest manufacturer for Cements and Glasses in the world.

Anhui Ruitai factory area over 200, 000 Square Meters, grinding ball workshop have one advanced full-automatic casting production line for small diameter size ball and one automatic casting production line for large diameter size ball. Have two oil quenching and tempering automatic production line. Those modern equipment ensure product- grinding ball keep good quality. Grinding ball produce capacity over 4000 metric tons per month!

Anhui Ruitai have a professionally R&D team and an advanced laboratory for refractory material and grinding media. Supply design, development, manufacture, installation and servicing of grinding media ball to our customer in the world! Main product -- High chromium Casting grinding ball, used to cement, Mining, coal-fired power plant etc. This kind grinding ball increased resistance to wear and shocks, can take more profits to customers.

In cement market, we supply grinding ball to Conch Cement group, Lafarge Holcim, Taiwan cement group etc.; In mining market, we supply Grinding ball to China Aluminum Group, ZIJIN Mining, China National Gold Group etc., In Coal-fired power, we supply Grinding ball to China State Power Corp, China Huaneng Group etc.

In last three years, we exported grinding ball to Russia, East Asia, Southeast Asia, South Asia, Africa etc

Welcome to visit my company!