| Prod Model: |

D5822-7Y30 |

| Type Of Material: |

Permanent Magnet |

| Other Performance: |

N35 N38 N40 N42 N45 N48 N50 N52 |

| Magnetism Direction: |

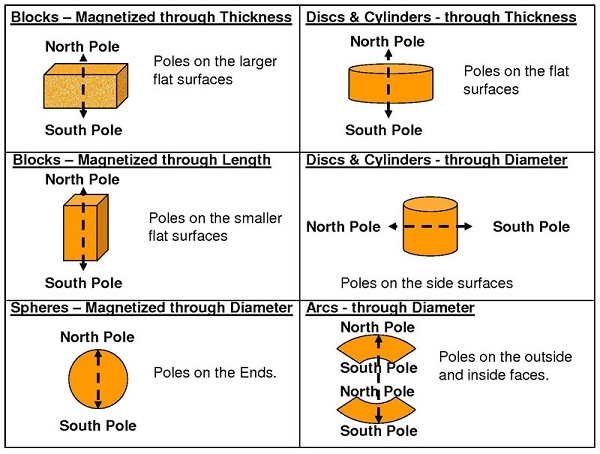

Axially |

| MOQ: |

1000 PCS |

| Delivery Detail: |

5-20 Days |

| Shipment: |

Express, Air, Ocean |

| Application: |

Medical Equipment |

| Shape: |

Rectangle |

| Coating: |

No Coated |

| Grade: |

N35-N52 |

Product Description

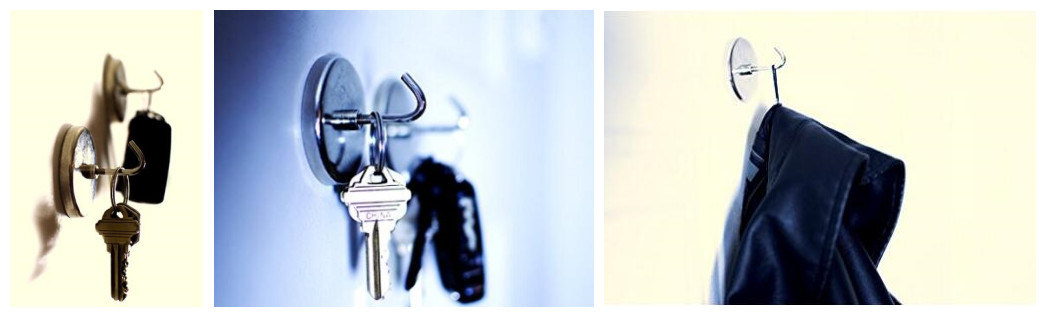

Product Description:Product Name:Hook Magnetic , great for hang, strong powerful heavy duty ferrite magnet.

| Type of Material | Permanent Ferrite |

| Grade | N35-N52 |

| Plating/Coating | No |

| Size | D58.7x7.2mm with Hole 22.3mm/ D2.31x0.28inch with Hole 0.88inch(Customizable) |

| Shape | Ring Shape |

| Magnetism Direction | Axially |

| Telerance | ±0.5mm to ±0.8mm |

| Delivery Detail | 7-20 Days |

| Packing Detail | Box, Carton, Plywood Pallet/Case |

| Shipment | By express, air or by sea |

Standard Specification For Sunny Fore Sintered NdFeB Magnets:| Grade | Remanence(Br) | Coercive Force (Hcb) | Intrinsic Coercive Force(Hcj) | Max Energy Product(BH) max | Working temp. |

| KGs | T | Koe | KA/m | KOe | KA/m | MGoe | Kj/m3 | ºC |

| N35 | 12.2-11.8 | 1.22-1.18 | ≥10.8 | ≥860 | ≥12.0 | ≥960 | 36-33 | 286-260 | ≤80 |

| N38 | 12.6-12.2 | 1.26-1.22 | ≥10.8 | ≥860 | ≥12.0 | ≥960 | 38-36 | 303-286 | ≤80 |

| N40 | 12.9-12.6 | 1.29-1.26 | ≥10.8 | ≥860 | ≥12.0 | ≥960 | 40-38 | 318-303 | ≤80 |

| N42 | 13.2-12.8 | 1.32-1.28 | ≥11.0 | ≥875 | ≥12.0 | ≥960 | 42-40 | 334-318 | ≤80 |

| N45 | 13.8-13.3 | 1.38-1.33 | ≥11.0 | ≥875 | ≥12.0 | ≥960 | 45-43 | 358-342 | ≤80 |

| N48 | 14.1-13.7 | 1.41-1.37 | ≥10.5 | ≥836 | ≥12.0 | ≥960 | 49-46 | 390-358 | ≤80 |

| N50 | 14.3-14.0 | 1.43-1.40 | ≥10.5 | ≥836 | ≥11.0 | ≥960 | 51-47 | 406-374 | ≤80 |

| N52 | 14.5-14.2 | 1.45-1.42 | ≥10.5 | ≥836 | ≥11.0 | ≥875 | 53-49 | 422-390 | ≤80 |

| N33M | 11.8-11.4 | 1.18-1.14 | ≥10.3 | ≥820 | ≥14.0 | ≥875 | 33-31 | 263-247 | ≤100 |

| N35M | 12.2-11.8 | 1.22-11.8 | ≥10.8 | ≥860 | ≥14.0 | ≥1114 | 36-33 | 286-260 | ≤100 |

| N38M | 12.6-12.2 | 1.26-12.2 | ≥11.0 | ≥875 | ≥14.0 | ≥1114 | 38-36 | 303-286 | ≤100 |

| N40M | 12.9-12.6 | 1.29-1.26 | ≥11.0 | ≥875 | ≥14.0 | ≥1114 | 40-38 | 318-303 | ≤100 |

| N42M | 13.2-12.8 | 1.32-1.28 | ≥11.5 | ≥910 | ≥14.0 | ≥1114 | 42-40 | 334-318 | ≤100 |

| N45M | 13.8-13.3 | 1.38-1.33 | ≥11.8 | ≥938 | ≥14.0 | ≥1114 | 45-43 | 358-334 | ≤100 |

| N48M | 14.1-13.7 | 1.41-1.37 | ≥11.8 | ≥938 | ≥14.0 | ≥1114 | 49-46 | 390-358 | ≤100 |

| N50M | 14.3-14.0 | 1.43-1.40 | ≥11.8 | ≥938 | ≥13.5 | ≥1075 | 51-47 | 406-374 | ≤100 |

| N30H | 11.4-10.8 | 1.14-1.08 | ≥9.8 | ≥780 | ≥17.0 | ≥1356 | 30-28 | 239-223 | ≤120 |

| N33H | 11.8-11.4 | 1.18-1.14 | ≥10.3 | ≥820 | ≥17.0 | ≥1356 | 33-31 | 263-247 | ≤120 |

| N35H | 12.2-11.8 | 1.22-1.18 | ≥10.8 | ≥860 | ≥17.0 | ≥1356 | 36-33 | 286-260 | ≤120 |

| N38H | 12.6-12.2 | 1.26-1.22 | ≥11.0 | ≥875 | ≥17.0 | ≥1356 | 38-36 | 303-286 | ≤120 |

| N40H | 12.9-12.6 | 1.29-1.26 | ≥11.0 | ≥875 | ≥17.0 | ≥1356 | 40-38 | 318-303 | ≤120 |

| N42H | 13.2-12.8 | 1.32-1.28 | ≥11.5 | ≥915 | ≥17.0 | ≥1356 | 42-40 | 334-318 | ≤120 |

| N45H | 13.8-13.3 | 1.38-1.33 | ≥11.8 | ≥938 | ≥17.0 | ≥1356 | 46-43 | 358-342 | ≤120 |

| N46H | 13.9-13.6 | 1.39-1.36 | ≥12.3 | ≥980 | ≥17.0 | ≥1356 | 47-44 | 374-345 | ≤120 |

| N48H | 14.1-13.7 | 1.41-1.37 | ≥12.6 | ≥1010 | ≥16.0 | ≥1270 | 49-46 | 390-358 | ≤120 |

| N30SH | 11.4-10.8 | 1.14-1.08 | ≥9.8 | ≥780 | ≥20.0 | ≥1600 | 30-28 | 239-223 | ≤150 |

| N33SH | 11.8-11.4 | 1.18-1.14 | ≥10.3 | ≥820 | ≥20.0 | ≥1600 | 33-31 | 263-247 | ≤150 |

| N35SH | 12.2-11.8 | 1.22-1.18 | ≥10.8 | ≥860 | ≥20.0 | ≥1600 | 36-33 | 286-260 | ≤150 |

| N38SH | 12.6-12.2 | 1.26-1.22 | ≥11.0 | ≥875 | ≥20.0 | ≥1600 | 38-36 | 303-286 | ≤150 |

| N40SH | 12.9-12.6 | 1.29-1.26 | ≥11.0 | ≥875 | ≥20.0 | ≥1600 | 40-38 | 318-303 | ≤150 |

| N42SH | 13.2-12.8 | 1.32-1.28 | ≥11.5 | ≥915 | ≥20.0 | ≥1600 | 42-40 | 334-318 | ≤150 |

| N45SH | 13.6-13.3 | 1.36-1.33 | ≥11.8 | ≥938 | ≥20.0 | ≥1600 | 46-42 | 358-334 | ≤150 |

| N28UH | 10.8-10.4 | 1.08-1.04 | ≥9.3 | ≥740 | ≥25.0 | ≥2000 | 28-26 | 223-207 | ≤180 |

| N30UH | 11.4-10.8 | 1.14-1.08 | ≥9.8 | ≥780 | ≥25.0 | ≥2000 | 30-28 | 239-223 | ≤180 |

| N33UH | 11.8-11.4 | 1.18-1.14 | ≥10.3 | ≥820 | ≥25.0 | ≥2000 | 33-31 | 263-247 | ≤180 |

| N35UH | 12.2-11.8 | 1.22-1.18 | ≥10.8 | ≥860 | ≥25.0 | ≥2000 | 36-33 | 286-260 | ≤180 |

| N38UH | 12.6-12.2 | 1.26-1.22 | ≥11.0 | ≥875 | ≥24.0 | ≥1910 | 38-36 | 286-260 | ≤180 |

| N28EH | 10.8-10.4 | 1.08-1.04 | ≥9.3 | ≥740 | ≥30.0 | ≥2400 | 28-26 | 223-207 | ≤200 |

| N30EH | 11.4-10.8 | 1.14-1.08 | ≥9.8 | ≥780 | ≥30.0 | ≥2400 | 30-28 | 239-223 | ≤200 |

| N33EH | 11.8-11.4 | 1.18-1.14 | ≥10.3 | ≥820 | ≥30.0 | ≥2400 | 33-31 | 263-274 | ≤200 |

| N35EH | 12.2-11.8 | 1.22-1.18 | ≥10.8 | ≥860 | ≥30.0 | ≥2400 | 36-33 | 286-270 | ≤200 |

Physical Properties:| Tem.Coeff.of Br: | -0.09~-0.11%/ºC |

| Density: | 7.5~7.6g/m3 |

| Vickers hardness: | 600Hv |

| Tensile Strength: | 8.0kg/mm2 |

| Specific Heat: | 0.12kcal(kg,ºC) |

| Young's.Modulus: | 1.6x1011N/m2 |

| Poisson's.Ratio: | 0.24 |

| Curie Temperature: | 310-340ºC |

| Temp.Coeff.of Hc: | 0.5~-0.60%/ºC |

| Electrical Resistivity: | 114µΩ.cm |

| Flexural Strength: | 25kg/mm |

| Coeff.of Thermal Expansion: | 4x10-6/ºC |

| Thermal Conductivity: | 7.7kcal(m.h.ºC) |

| Rigidity: | 0.64N/m2 |

| Compressibility: | 9.8x10-2m2/N |

| Relative Recoil Permeability: | 1.05 |

Characteristic of Surface Treatment:| Performance | Zn | Double Ni | NiCuNi | Electroless Ni | Epoxy |

| Colour | White | Silver | Silver | Silver | Black |

| Thickness(µ M) | 8-15 | 15-20 | 15-30 | 10-20 | 10-30 |

| Pressure Cooker Test (120C,2atm,10%RH) | >15hr | >24hr | >48hr | >24hr | >24hr |

| Salt Spray Test (5%NaCl,35ºC,1.2atm) | >24hr | >24hr | >48hr | >72hr | >100hr |

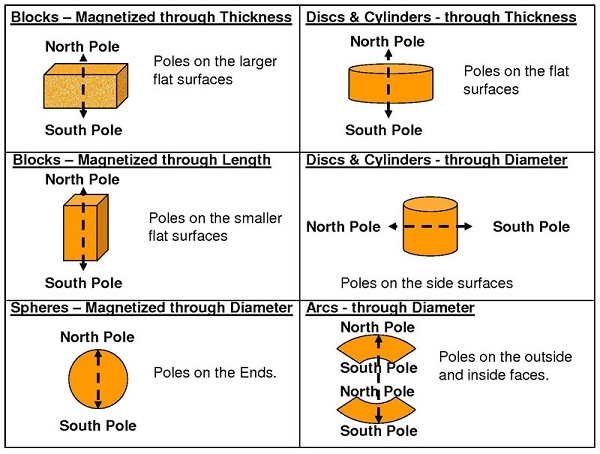

Magnetization of Direction: Packing DetailSunny Fore have over 16 years export experience.

Packing DetailSunny Fore have over 16 years export experience.

The fastest way fo delivery , we have agreed framwork with FedEx, TNT, DHL, UPS etc, we provide the best freight charges.

Magnet is special goods for shipment , they need to make special packing when shippment is shipped by air, Sunny Fore have 10 years export experience and transportaion experience, We will arrange air shipment in good condtion.

Contact Us!

Any question feel free to contact us, we will try our best to meent your requiement.

About us

SUNNY FORE MAGNET CO.,LTD. is locathed in Jiangmen city in Guangdong, we are specialized in MAGNET product for more than 20 years, such as Sintered NdFeB Magnets, Bonded NdFeB Magnets and Rubber Magnet and so on. We have own advanced production equipment and professional testing equipment, to provide our clients with competitive products. In order to overcome the chanllege that suport, solidarity and cooperation to creat a better future.

Quality Control:

Sunny Fore Magnet is approved by ISO 9001:2008 quality system. For more than 16 years export experience and 20 years magnet factory proucting, integrity to provide valued products and customer-satisfied services.

FAQQ: Are you trading company or manufacturer ?

A: We are factory, and have export magnet experience for more than 10 years.

Q: How long is your delivery time ?

A: Generally it is 3-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge if the samples is in stock, but do not pay the cost of freight.

Q: Does the magnet acceptable shiped by airfreight ?

A: Of cause, magnet can be shiped by air after special packing.

Jiangmen XinLike Magnet Company Limited specializes in producing MAGNETS, including Neodymium magnet, NdFeB magnet, and Rubber magnet.

Our company is located in Jiangmen city, Guangdong. Basic on Pearl River Delta economic zone, which is one of China's leading economic regions and a major manufacturing center. Jiangmen city is 100 kliometers away from Guangzhou, Dong guan 60 Kilometer, Shenzhen 90 kilometer, and Hong Kong 150 kilometer.

We insist on Quality Policy of "customer first, quality first, Refined management and continuous improvement" and "people-oriented, technological-innovation and integrity-Operating" management concept. Also, we have successfully passed the ISO9001-2008 quality system certification.

Thanks to more than 10 years experience on magnetic material and more than 500 000 pieces production capacity, with experienced production skills and perfect quality management system, we can supply our customer with innovative and nice stability products.

We will complete customized samples for your in just 3 days and then finish your orders in 7 days. Our R and D Engineers are experts in developing ND-Fe-B, rare-earth and permanent magnet types in shapes and size to suit your needs.

To put this experience to work for you, start by placing an order for just 500USDOLLAR today. We believe that we can win your reliance and support with our best service with high quality products