Home Toolbuy Products Jh25 250 Ton C Frame Sheet Metal Mechanical Stamping Punching Power Press/ Stamping Press / Punch Press/ Crank Press

Jh25 250 Ton C Frame Sheet Metal Mechanical Stamping Punching Power Press/ Stamping Press / Punch Press/ Crank Press

| Price: |

Negotiable/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: |

Jh25 |

| Delivery Time: |

1 Month |

| Application: |

Progressive Die Stamping |

| Type: |

General Punching Machine |

| Controlling Mode: |

Artificial |

| Automatic Grade: |

Automatic |

| Power Source: |

Mechanical Drive |

| Precision: |

High Precision |

Product Description

Details:

The JH25 C-frame double crank press is the commonly used product in blanking, piercing and cutting the larger piece of sheet metal.

The worktable in large size is more suitable for the progressive dies working on different stations, which can greatly improve the production efficiency.

FEATURES:

1. Welded body with steel plate and high intensity;

2.Suitable for multiple dies automatic line and multi level dies continuous punching;

3.Double crankshaft pitmen totally eliminating side forces by reverse rotation;

4.Combined wet multi discs friction clutch and brake;

5.Cluster gear adopts the flooding oil lubrication;

6.Six-face rectangle lengthen guide;

7.Adopts electric die height adjustment with digital display;

8.Equipped with hydraulic overload protecting device.| Specifications of JH25 Series C-frame Two Points Press |

| Parameter | | Unit | JH25-110 | JH25-160 | JH25-200 | JH25-250 | JH25-315 |

| Nominal Capacity | | KN | 1100 | 1600 | 2000 | 2500 | 3150 |

| Nominal Stroke | | mm | 5 | 6 | 7 | 7 | 7 |

| Slide Stroke Length | S | mm | 180 | 200 | 250 | 280 | 280 |

| H | mm | 110 | 130 | 150 | 170 | 170 |

| Slide Stroke | Fixed | S | times/min | 50 | 45 | 35 | 30 | 30 |

| H | times/min | 70 | 60 | 50 | 45 | 40 |

| Variable | S | times/min | 35-65 | 35-55 | 25-40 | 20-35 | 20-35 |

| H | times/min | 45-85 | 40-70 | 30-60 | 30-50 | 30-45 |

| Max. Die Set Height | S | mm | 400 | 450 | 500 | 550 | 550 |

| H | mm | 435 | 485 | 550 | 605 | 605 |

| Die Height Adjustment | | mm | 90 | 100 | 110 | 120 | 120 |

| Throat Depth | | mm | 350 | 390 | 430 | 470 | 480 |

| Distance Between Uprights | | mm | 1470 | 1600 | 1920 | 2190 | 2170 |

| Bolster Size | F x B | | mm | 680 | 760 | 840 | 920 | 940 |

| L x R | | 1880 | 2040 | 2420 | 2700 | 2800 |

| Bolster Thickness | | mm | 155 | 165 | 170 | 180 | 190 |

| Slide Bottom Size | F x B | | mm | 520 | 580 | 650 | 700 | 700 |

| L x R | | 1400 | 1500 | 1850 | 2100 | 2100 |

| Bolster Surface Height | | mm | 900 | 900 | 1000 | 1100 | 1090 |

| Overall Size | F x B | | mm | 1820 | 2080 | 2370 | 2700 | 2730 |

| L x R | | 1970 | 2150 | 2550 | 2850 | 2840 |

| H | | 3200 | 3380 | 3820 | 4180 | 4180 |

| Motor Power | | Kw | 11 | 18.5 | 22 | 30 | 37 |

| Weight | | Kg | 14000 | 19000 | 26500 | 35000 | 36000 |

| Press Pressure | | Mpa | 0.5 |

B

B| Standard Equipments: | Optional Equipments: |

| 1) Wet clutch | 1) Light curtain |

| 2) Hydraulic overload protecting pump | 2) Foot pedal |

| 3) Auto lubrication system | 3) Leather bag die cushion |

| 4) Manual lubrication system | 4) Die quick change device |

| 5) Balance cylinders for slide and upper die | 5) Auto feed shaft |

| 6) Digital die height indicator | 6) Inverter |

| 7) Joint for miss-feeding | 7) Absorbing pads |

| 8) Touch screen | |

| 9) Electronic crankshaft angle indicator | |

| 10) Cam controller | |

| 11) Movable control panel | |

| 12) Die height adjusted motor | |

| 13) PLC | |

| 14) Device for knockout | |

| 15) Joint for air | |

| 16) Foundation bolts | |

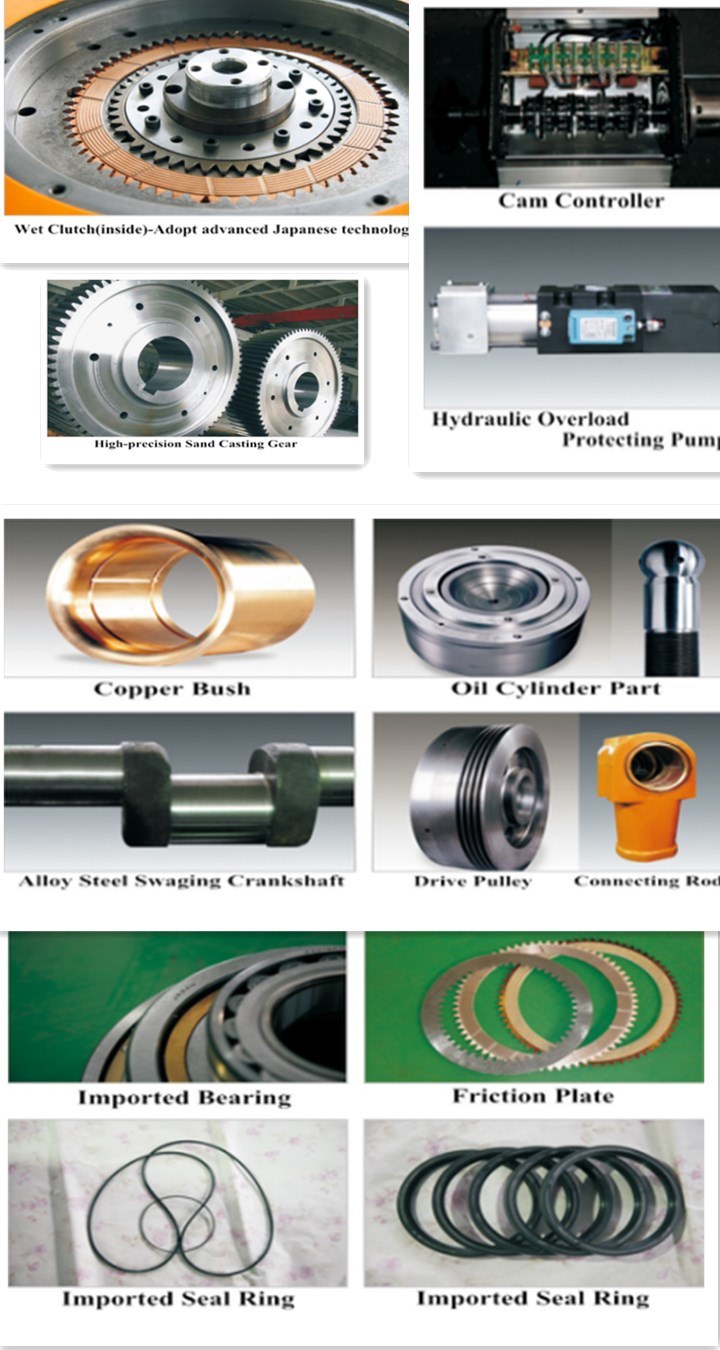

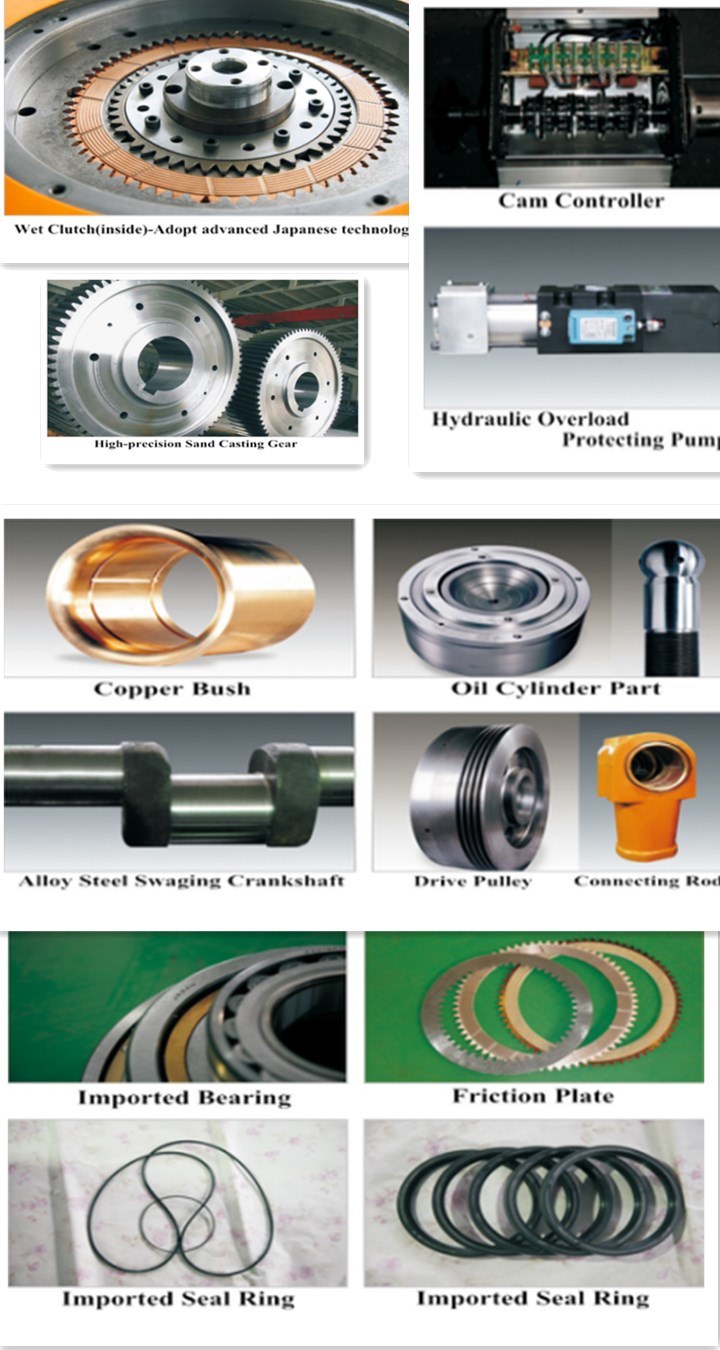

outique Accessories:

Our Equipment :

Advanced Technological Power :

World (Shanghai) R&D center cooperate with the professional companies in USA, Germany, France, Japan, Sweden and the colleges and universities in china so as to develop and perfect the products with superb technique promptly.

Additionally, authority organization in the field supervises the quality from the parts to the whole machine. professional team with craft design and assembly ensures the accuracy of parts.

We establish R&D center in Shanghai to welcome more excellent talents and develop new craft.

Jinan forging and welding bureau, Shanghai press machine supervision station monitor the quality of parts; the team of professional craft design and manufacture ensure the accuracy of parts based on the excellent craft.

After Service:

In this world, people cooperate with WORLD customers every day. The quality of WORLD products is facing test and they are endowed with great mission.

World thinks quality service is not only simple maintenance. Our service engineers not only find problem for taking action in advance but also advise how to use the machine more properly and carefully.

Worldwide service network and convenient service show the strong responsibility and sense of historical mission.

To all of our customers:

Our best greeting is given to the esteemed customers of World Precise Machinery (Jiangsu) Co. Ltd.

We appreciate that you purchase our presses of varieties of types. we produce about 30 series of presses including300 types of big, intermediate and small presses, such as ordinary numerically controlled guillotine shear, ordinary numerically controlled bending machine, full numerically controlled bending machine, numerically controlled turret punching-machine and varieties of types of oil hydraulic presses.

Guaranty:

If you purchase our product, we promise that the length of warranty for mechanical part is one year and the length of warranty for electrical part is one year and the length of warranty for electrical part is half one year.

Marketing Service Center Headquarters of World Precise Machinery (Jiangsu) Co. Ltd.

Mail : [email protected]

World precise machinery group (hereinafter refers to world precise machinery) establishes in 1953 which is located in Shanghai economic zoom., world precise machinery is the beginning of the first five years planning of China, is one of the oldest and most professional manufacture of punching equipments. After listing in Singapore market, world's products are paid great attention with high quality and superb technique.

World precise machinery group optimized and merged in 2016, including subsidiaries as world precise machinery and world Shenyang. In the headquarter of the group, there are press technical R&D center, numerical control technical center, heavy tools technical center. Additionally, there is a conventional R&D center in Shanghai which can cooperate with the professional companies in USA, Germany, France, Japan, Sweden and the colleges and universities in China so that develop and perfect the products with superb technology. World's products contain all the products of Shanghai press machine factory, Shanghai second press machine factory and Shanghai press and shearing machine factory. It includes 30 series 300 types of products such as all types of presses, shearing machines, bending machines and punching machines. They are widely applied in the fields of space, automobile manufacture, communications and computers. WORLD Precise Machinery has established sales network and service organizations in large and medium-sized cities across the country, and the products are even exported to Southeast Asia, Europe, South America and South Africa. It is the forging equipment manufacturer with the largest scale, most kinds, and widest sales service network in the industry.

Industry is the base of a strong country. World precise machinery is endowed with this great mission since its establishment. As Chinese industry is developing day by day, world precise machinery is with the same step of world economy and sets goals:

The manufacture base with strong competitive power;

Top-level bending equipment manufacture base;

The biggest manufacture of pressing machine.