| Prod Model: |

MP23 |

| Voltage: |

3 Phase 380V 50Hz or as Requested |

| Colour: |

Green or as Requested |

| Model: |

MP23 |

| Adjuatable Stroke: |

D Type |

| Type: |

General Punching Machine |

| Controlling Mode: |

Artificial |

| Automatic Grade: |

Manual |

| Power Source: |

Mechanical Drive |

| Precision: |

Normal Precision |

Product Description

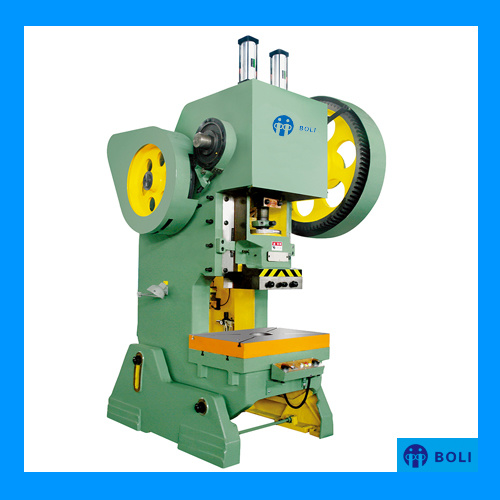

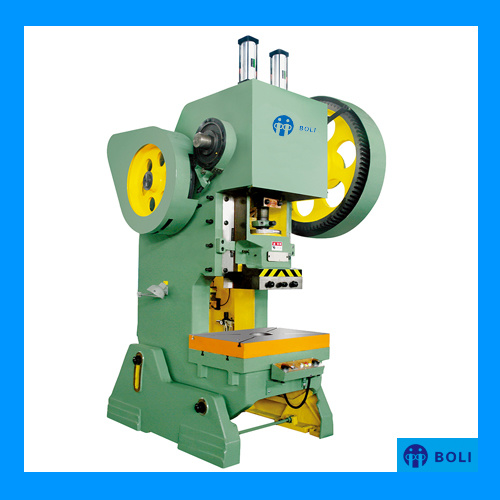

MP23 series C-Frame Inclinable Press Machine

Features:

> MP23-25 open type inclinable press machine is the first to adopt rolling rather than the commonly used sliding bearing( copper bearing) for the transmission gear, which make the transmission gear more wear-resistant and avoid loud noises of gears caused by the quick worm copper bearing.

> MP23-25 open type inclinable press machine is unique in the industry. Other 35T press machines produced by other manufactures in the country all adopt a machine body of the 25T machine and copper bearing for the transmission gear. We are the only manufacture that redesigns the machine body, the 35T machine body is far more heavier than the 25T machine body, and the strength is also better, with the rolling bearing transmission( low gear noise), which equal to the light 40T press machine.

> the 80T-level press machine all adopt the structure of pneumatic dual balance cylinder, which has small fluctuate of the balance force and it balances the slider and the die, which prevent the lathe from being unstable. And it can also avoid the clash and noise caused by the converse stress of gears in transmission, eliminate the clearance between connecting rod and slide, reduce the compact and wear of stress parts, and avoid accidents caused by the falling of slider when the brake falls or the connecting rod ruptures.

Specification:

| model | MP23-6.3 | MP23-10 | MP23-16 | MP23-25 | MP23-35 | MP23-40 | MP23-63B | MP23-80 | MP23-100 | MP23-125 |

| nominal force | KN | 63 | 100 | 160 | 250 | 350 | 400 | 630 | 800 | 1000 | 1250 |

| nominal stroke | mm | 2 | 2 | 2 | 2.5 | 3.5 | 6 | 7 | 7 | 7 | 8 |

| slide stroke | mm | 35 | 45 | 55 | 65 | 80 | 90 | 110 | 120 | 140 | 150 |

| SPM | high speed | min -1 | 170 | 145 | 125 | | | | | | | |

| low speed | min -1 | | | | 55 | 50 | 45 | 40 | 38 | 38 | 35 |

| max. die height | mm | 150 | 180 | 220 | 270 | 290 | 320 | 390 | 440 | 480 | 500 |

| die height adjustment | mm | 30 | 35 | 45 | 55 | 60 | 65 | 80 | 90 | 100 | 100 |

| between slide center and frame | mm | 110 | 130 | 160 | 200 | 220 | 250 | 310 | 350 | 380 | 390 |

| between columns | mm | 150 | 180 | 220 | 270 | 280 | 340 | 420 | 450 | 560 | 550 |

| slide area(FBxLR) | mm | 120x140 | 150x170 | 180x200 | 220x250 | 220x250 | 260x300 | 360x400 | 360x430 | 480x540 | 480x540 |

| shank hole(dia x depth) | mm | Φ 30x55 | Φ 30x55 | Φ 40x60 | Φ 40x60 | Φ 40x60 | Φ 50x70 | Φ 50x70 | Φ 60x75 | Φ 60x75 | Φ 60x75 |

| bolster(FBxLR) | mm | 200x310 | 240x370 | 300x450 | 370x560 | 400x610 | 460x700 | 570x860 | 650x950 | 710x1080 | 720x1100 |

| bolster opening dia | mm | 60 | 80 | 100 | 120 | 120 | 150 | 180 | 200 | 220 | 180 |

| bolster thickness | mm | 30 | 35 | 40 | 50 | 60 | 65 | 80 | 100 | 120 | 130 |

| Max. inclined angle | ° | 45 | 35 | 35 | 30 | 30 | 30 | 20 | 20 | 15 | 13 |

| bolster serface height | mm | 750 | 730 | 750 | 800 | 815 | 850 | 850 | 850 | 850 | 860 |

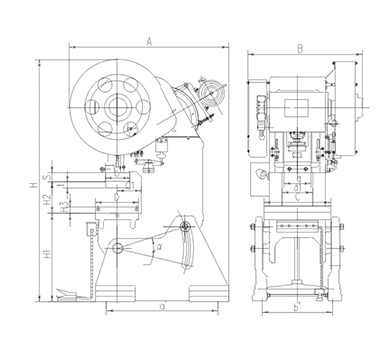

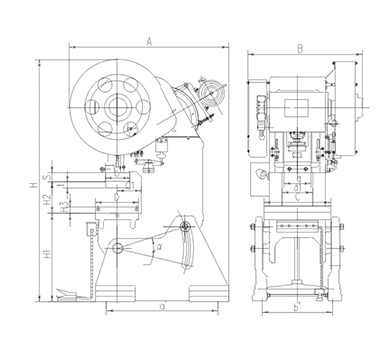

| outline dimension(FBxLRxH) | mm | 780x620x1503 | 9000x665x1658 | 1150x847x1910 | 1345x950x2130 | 1460x1058x2225 | 1721x1335x2488 | 1958x1500x2868 | 2060x1715x3290 | 2404x1790x3625 | 2504x1790x3715 |

| main motor power | KW | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 7.5 | 11 | 11 |

| net weight | KG | 400 | 576 | 1085 | 1780 | 2650 | 3540 | 5500 | 7390 | 10800 | 12035 |

Our company supplies different kinds of machines. High quality and favorable price. We're pleased to

Get your Inquiry and we will come back to as soon as possible. We stick to the principle of " Quality

First, service first, continuous improvement and innovation to meet the customers" For the

Management and " Zero defect, zero complaints" As the quality objective. We have a good sales and

Design team for satisfy customer's inquire, all equipment must use higher standard for produce the

Machine. Before leave the manufacture, we have professional engineer will arrive

The factory for check each machine, confirm the quality, after get the engineer's

Agreement we will export the machine to customer