| Prod Model: |

21112054186 |

| Structure: |

Open/Closed-Cell Structure |

| The Most Big Size: |

10000 Mml X 1000 Mmw X 2~40 Mmt |

| Adhesive Tape: |

3m, Tesa, Nitto, Aluminum Foil, Lining Cloth |

| Usage: |

Industrial Rubber Slab, Industrial, Flooring, Printing, Rubber Floor Covering, Automobile, Airconditioning, Refrigerator |

| Raw Materials: |

Natural Rubber, Pad |

| Medium: |

Pure Gum Rubber Sheet and Fabric |

| Performance: |

Oil-Resisting Asbestos-Rubber Sheets |

| Material: |

NBR&PVC |

Product Description

NBR ( nitrile -butadiene rubber) and PVC ( Poly Vinyl Chloride) is the main mixture material in plastic-rubber foam industry. NBR/PVC mixture has both PVC's feature ozone resistance and NBR's feature oil resistivity except of its performance of crosslinking, plus a bit fire resistance. It also functions with good physical property. Due to sourceful and inexpensive PVC as raw material, such blended foam is widely used in many fields.

| DENSITY (KG/M3) | COL. | HARDNESS (SHORE C) | TEMPRERATURE RESISTANCE(ºC) | TENSILE STRENGTH(KPA) | ELONGATION (%) |

| 60-90 | BLACK | 12-18 | -40-90 | ≥168 | ≥156 |

1.Clearly boost the attributes of ozone-resistance and weatherability

2.Improve the functions of tensile strength, elongation, tear resistance, heat resistance and fire resistance.

3.Further the performances of oil resistivity, resistances to some chemicals.

4.Expand the possibility of extrusion and drawability,self-vulcanization resistance to strengthen its storage stability.

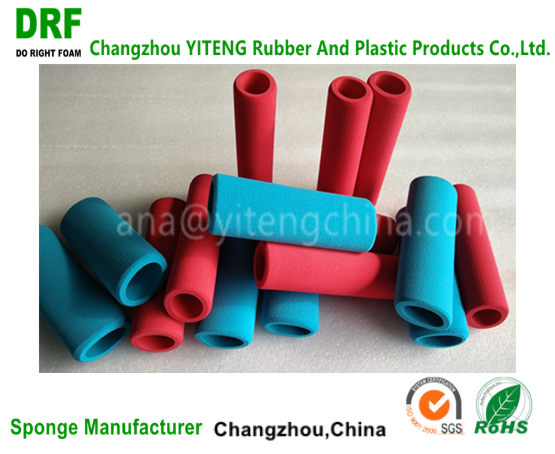

5.Easy to tint, made colorfully.

10000 mmL X 1000 mmW X 2~40 mmT

original bun, block, sheet, rolls, one-side skin and both-side skin

According to density,indoor or outdoor,temperature

Good elastic&compressive,good buffering,impact resistance,ANTI-UV,corrision resistance,low temperature resistant,sound insulation,sealing,flame retardant,fire proof

Automobile, airconditioning, refrigerator, home application, refrigeration project,building.

Raw material stired and mixed→Heating,foaming→Length,Width,Thickness Cutting→Function Inspection→Initial Adhesion Testing(Testing Equipment)→Constant Adhesion Testing(Tesing Equipment)→Punching→Size Testing→Silent Dust→Packing(Customer Request)→Shipment

OPP bag and Carton or customized

1. We are manufacturer more than 8 years,we have complete technical data.

2. Factory directly sell, so you can get the most competitive price.

3. The most advanced equipments to keep the quality and quantity.

4. We have the approval of EN71,UL,SGS, ISO9001-2008, Reach.

5. The most professional supplier, any color,size according to your requests.

6. We guarantee the quality and service.

7. OEM is warmly welcomed.

Changzhou YITENG Rubber and Plastic Products Co., Ltd. Founded in 2008, is specialized company, which is committed to exploit, manufacture and process plastic-rubber foamed material. Our products include EPDM foam, NBR foam, CR foam, NBR/PVC extrusion foam, PE foam, EVA foam, plastic-rubber foam, sponges, slow-rebounding foam, SBR laminated with fabrics, foams of thermoplastic elastomer. We also possess high-precision processing equipments such as horizontal cutting, slitting, gluing, die cutting and so on, in terms of different customization, such foams are made into sheets, sponge gluing strip, as well as various different shapes etc.

Our foam material features with the attributes as follow: Excellent heat-preservation, heat-insulation, poor water-permeability, buffering, vibration resistance, plus small volume-weight, sound absorption, sound insulation, as well as outstanding weatherability, superior oil resistivity, solvent resistance, resistance to chemical reagent. In order to meet the needs in some special environments, we can manufacture some peculiar foams of fire resistance, electric conduction, being antistatic.

Our foam products function as accessories in feature of heat insulation, buffering, being waterproof, sound absorption, widely applied in automobile, vessel, locomotive, subway, airconditioning, electronics, sounding, architecture, bridge, mechanics, travel products, commodities and some other fields.