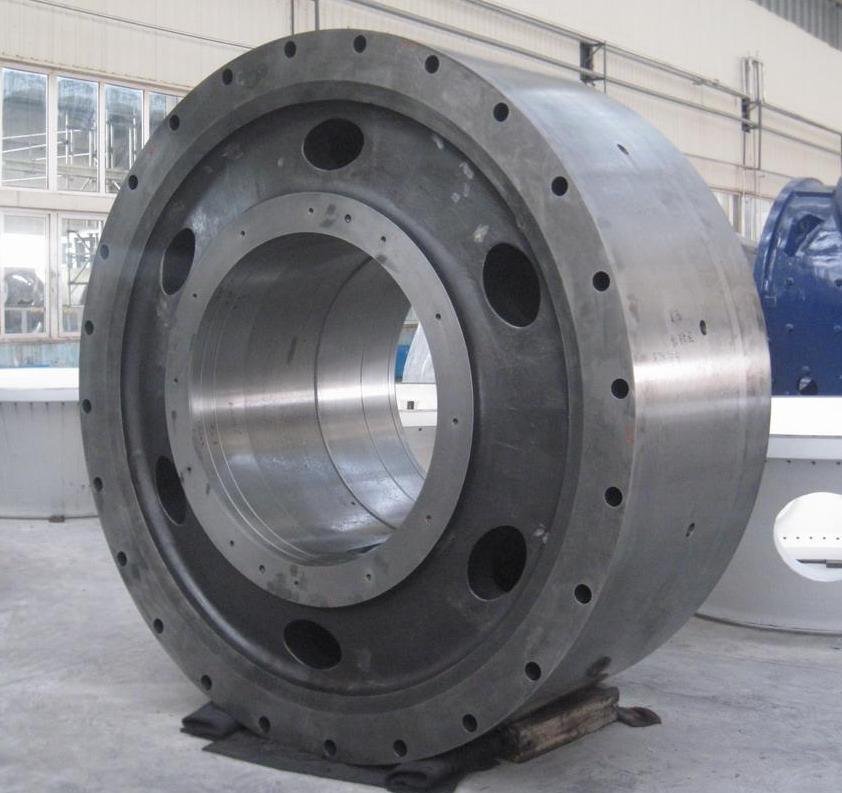

OEM Grey Iron/Ductile Iron/Sand Casting with CNC Precision Machining

| Price: |

US $ 10/Piece |

| Min Order: |

50/Piece |

| Pay Type: |

L/C,T/T,Western Union |

| Type: |

Chemical Hardening Sand |

Product Description

OEM Grey Iron/Ductile Iron/Sand Casting with CNC Precision Machining

1)Established in 2006, located in Dongguan city, Guangdong province, China.

2)Have more than 10 years export experiences.

3)Engineers have engaged in casting field more than 30 years.

Our product: Process | Lost Wax Casting, Investment Casting, Sand casting. Gravity casting, Forging |

Specification | 1.Material: stainless steel.carbon steel ,iron, brass...etc 2.Standard: ASTM\DIN\BS\JIS\GB. 3.Surface finish: shot blasting,sand blasting, polishing,painting, galvanized,etc. 4.Weight: upto 7000kg. |

Production facility | 1.Casting facility:sand mixer,molding machine,electric furnace, molding production line, annealing production line,box resistance furnace, heat treatment furnace,shot-blasting machine, sand-blasting machine, medium-frequency induction furnace,flame cutting machine, galvanizing line. 2.Machining facility: CNC, NC lathe,ordinary machine tools,linear cutting machine, polishing machine. |

Heat treatment | Annealing/Tempering/Normalizing. |

Test facility | spectrometer, tensile test machine, hardness test machine,impact tester,CMM |

Machining :

Machining : Packing:

Packing:

Our Company

Our Company

Since its establishment,special and professional commitment to the lost wax investment castings and the construction hardware of the precast concrete industry.

With advanced production equipment, well-equipped testing facilities,strong technical force, perfect management and high-quality assurance system.

Our company has more than one hundred employees with professional skills.We are trained with regularity, experienced workforce, and excellent and full-range pre - sales,, sales, and after-sales services.

<1>. Company Overview :

Business Type: Manufacturer/Importer and Exporter

Factory Size : 5000 square meters

Contract Manufacturing : OEM service , Design Service , Buyer Label offered

Annual Output Value : US$ 30 Million

Total Employees : 100 people

Year Established: 2006

<2>. Main equipments :

Wax Injection Machine

Air Compressor

Sand Spraying Machine

Dewaxing Machine

Roasting Furnace

Metal Melting Furnace

Spectrometer

Induction Heating Furnace

Cutting machine

arc welding machine

Tensile Strength test machine

Our Advantages:

We can do the lost casting,sand casting, gravity casting,forging and accembly by our own factory

Strict qualitify control for the raw material

Perfect production process for each part

The most advanced equipments for production and inspection

On time delivery

Flexible payment way

FCL or LCL both acceptable

Diversified packaging according to requirement

FAQS:

Q1. Do you can get a free sample?

(1) Any new buyer can get a free sample .

(2) Sample can be received with 10 days

Q2.How long of our production time ?

(1)After confirmed the sample, it usually takes about 15-35 days

Q3.How about our MOQ?

(1)we welcome all buyers over the world,any order can be acceptable.

(2)Bigger order can get some corresponding discount.

Q4.What kind of trade term we take ?

(1)The FOB and CIF trade terms are usually choosen

(2)If you are not familia with the trade terms, we can provide you the support.

Q5.what kind of payment term we take?

(1) We mostly take the T/T and L/C payment , the paypal or other online payment ways are avaiable ,too.CONTACT:General Manager: Sherry Luo

Tel: 86-769-89865086

Mobile: 86-13712854626

www.lifestylecasting.comWelcome to inquiry!

DONGGUAN LIFE-STYLE CASTING Co., Ltd. is located in Dongguan city, which is close to Guangzhou and Shenzhen, it just take 30munites to Guangzhou & Shenzhen. The manufacturing site 10, 000M2, including office building. Sample show, machining show, casting working shop. etc...

Life-style produces a wide variety of high-grade precision casting and machined parts in stainless steel. Heat-resistant steel, carbon steel low alloy steel, brass, iron, Grey Iron, Ductile Iron and other materials.

By casting: Silica sol investment castings, lost wax casting, precision casting, die casting, sand casting, water glass casting process, shell casting process...

Precision machining: Drill machining, tapping, CNC leather, laser engraving...

Surface treatment: Grinding, mirror polishing, matte polishing, sand blasting, painting, black coating, etc.

Life-style serves in a wide range of fields of Automotive industry, Marine industry, Food machinery, Engineer industry, Pump&Valve, electronic kitchen appliances, Medical equipment hardware tools, jewelry Industry...etc.

Life style has over 100 customer, with a monthly capacity 80-100tons of high quality precision casting parts. More than 70% casting are exported to oversea marketing. Including USA, Canada, EU, Japan, Australia. New Zealand, Singapore, Malaysia, Thailand...etc.

Our foundry is by international standards: ISO, ANSI, ASTM, , JIS, DIN, GB etc

Our parts weight is: 0.5kg - 500kg

Life-style regards human resources as the basis, advanced equipments and techniques, sophisticated management system, and strong quality assurance capacity, quality as the life of enterprise and meeting customers' requirements as the company major objective, continuous improvement to perfection is the company's major objective continuous improvement to perfection is the company's quality system.

Life-style will continue to cooperate with more overseas and domestic customers to further development with its best products and services. Warmly welcomes the inquiries from various customers by sending us E-mail with drawings or samples pictures. We will give prompt reply to any inquiries from the customers. Advancing together with the customers is our ultimate objective.