| Prod Model: |

SY0053 |

| Advantage: |

Quality & Price. |

| Segment Shape: |

Flat "U" " T" "W" "M", Conical Shape |

| Delivery Detail: |

7 - 15 Days |

| Segment Type: |

Abrasive Segments |

| Certification: |

SGS |

| Shape: |

Conical Marble Segment |

Product Description

Our 2017 Las Vegas World of Concrete Exhibiton Booth No is S11849 WELCOME!

We supply many kinds of grinding pad to our clients which working for Floor maintainance or doing concrete polishing project. We supply the tools to match with their HTC, Husqvarna, Klindex, Lavina,Scanmaskin, etc.

We supply many kinds of grinding pad to our clients which working for Floor maintainance or doing concrete polishing project. We supply the tools to match with their HTC, Husqvarna, Klindex, Lavina,Scanmaskin, etc. Below is a brief description of each segment type and typical application.

Below is a brief description of each segment type and typical application.

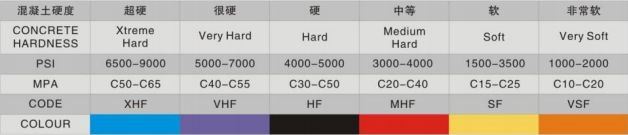

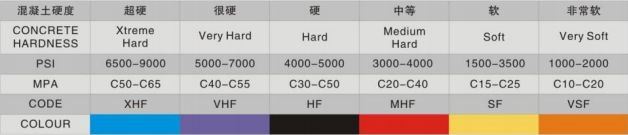

Bond - The strength of the metal binder that holds the diamond grit in the segment. Typically the harder the bond the longer the life. An abrasive subfloor will require a harder bond. A harder floor will require a softer bond.Grit - 16/20#, 30-220#, 350/400#Concrete - can be soft, hard, abrasive, dusty and brittle etc. No two floors are ever the same, typically they are more abrasive when new or have a high sharp sand content. The more abrasive the floor the harder bond you will need to get the best performance out of the diamonds. Company infomation:QUANZHOU SUNNY SUPERHARD TOOLS CO.,LTD is a professional and dynamic diamond tools manufacturer,established in 1993, located in Quanzhou, Fujian Province, China. Factory covering 15000 square meters. Our technical department is composed of experienced professors and engineers. Main Products: Dimaond construction tools: Concrete blade, wire saw, grinding shoes, grinding wheels, core drill bits, etc) Diamond Stone Tools (Saw blade, Segment, Wire saw,Calibration rollers, Fickerts, Frankfurt, Cup wheel, Profiling wheel, Polishing pad, Brush,Finger bit, Core drill, etc)We wish to get your collaboration to achieve our objectives together!

Company infomation:QUANZHOU SUNNY SUPERHARD TOOLS CO.,LTD is a professional and dynamic diamond tools manufacturer,established in 1993, located in Quanzhou, Fujian Province, China. Factory covering 15000 square meters. Our technical department is composed of experienced professors and engineers. Main Products: Dimaond construction tools: Concrete blade, wire saw, grinding shoes, grinding wheels, core drill bits, etc) Diamond Stone Tools (Saw blade, Segment, Wire saw,Calibration rollers, Fickerts, Frankfurt, Cup wheel, Profiling wheel, Polishing pad, Brush,Finger bit, Core drill, etc)We wish to get your collaboration to achieve our objectives together!

FAQ:

FAQ:a. Diamond fall off from segment

Happen to sudden shock during cutting;

Extra cutting speed;

Blade vibration;

Cutting material, flange or blade not fix;

Bond too soft to hold diamond;

Powder has too much air hole or gap;

b. Big noise

Water supply not sufficient;

RPM not suitable;

Segment width small, cause steel blank scrath;

Cutting material not fix | c. Segment off

Happen to sudden shock during cutting;

Cutting material flange or blade not fix;

Cutting material too hard;

Water supply insufficient;

d. Short cutting life

Water supply insufficient;

Electricity not stable;

Belt loose;

Bond not suitable;

e. Blade don't work

Bond too hard;

Insufficient electricity;

Segment not sharpen; |

Advantage:WHY CHOOSE US?

1. More than 22 years experience in diamnd tools;

2. Get knowledge of market demand;

3. 12 experienced professors and engineers;

4. High efficiency production flow;

5. Strict quality control system;

6. Exported to more than 60 countries;

7. Professional sales team with prompt reply;

Contact us:Quanzhou Sunny Superhard Tools Co., Ltd.

Add: Tangxi Industrial Zone, Luojiang, Quanzhou, Fujian, China

Postcode:362010

TEL: 86 - 595 - 22003682

FAX: 86 - 595 - 22003987

Web: http://www.sunnytools.biz

http://www.concretetoolsunny.com

QUANZHOU SUNNY SUPERHARD TOOLS Co., Ltd is a professional and Dynamic Diamond Tools manufacturer, established in 1993, Located in Quanzhou, Fujian province, China, factory covering 15000 square meters. Our technical department is composed of experienced professors and engineers. We devote ourselves to researching and manufacturing cutting and processing Diamond tools for nature stone and building materials. Our tools are exported to more than 60 countries, including America, Brazil, Italy, Russia, Ukraine, India, Egypt, South Africa etc.

Main Products:

Cutting Tools (Saw blade, Segment, Wire saw etc)

Grinding&Polishing Tools (Calibration Rollers, Fickerts, Frankfurt, Cup wheel, Profilling wheel, Polishing pad, brush etc)

Drilling Tools (Finger Bit, Core drill etc)

The Philosophy of Sunny is "Superior product and service derived from standard and efficWe have a high efficiency team, each department strictly comply with company regulations.

From receiving your enquiry, put order in production and Dispatch to after-sales service, Ient management. "

In order to provide customer most suitable tools, we keep researching and analysing nature stone and engineering material. We cooperate with stone factory to test tools, and keep close contact with our customers by visit or communication to get knowledge of market demand.

We Response All Your Request efficiently To Save Your Time And Provide Your Utmost Convenience.

The deep understanding for customer's demand and strict quality control help us developing quickly, we wish to get your collaboration to achieve our objectives together!

Our aim is to provide our clients stable and consistant quality with competitive price.

Advantages enable clients benefits from our tools.

1. Experienced bond system

2. Advanced equipment and high grade raw material

3. Strictly production procedures control and quality inspection.

4. Customer's active feedback and support help us developing fast.