| Precision: |

High Precision |

| HRC: |

45/55/60/65 HRC |

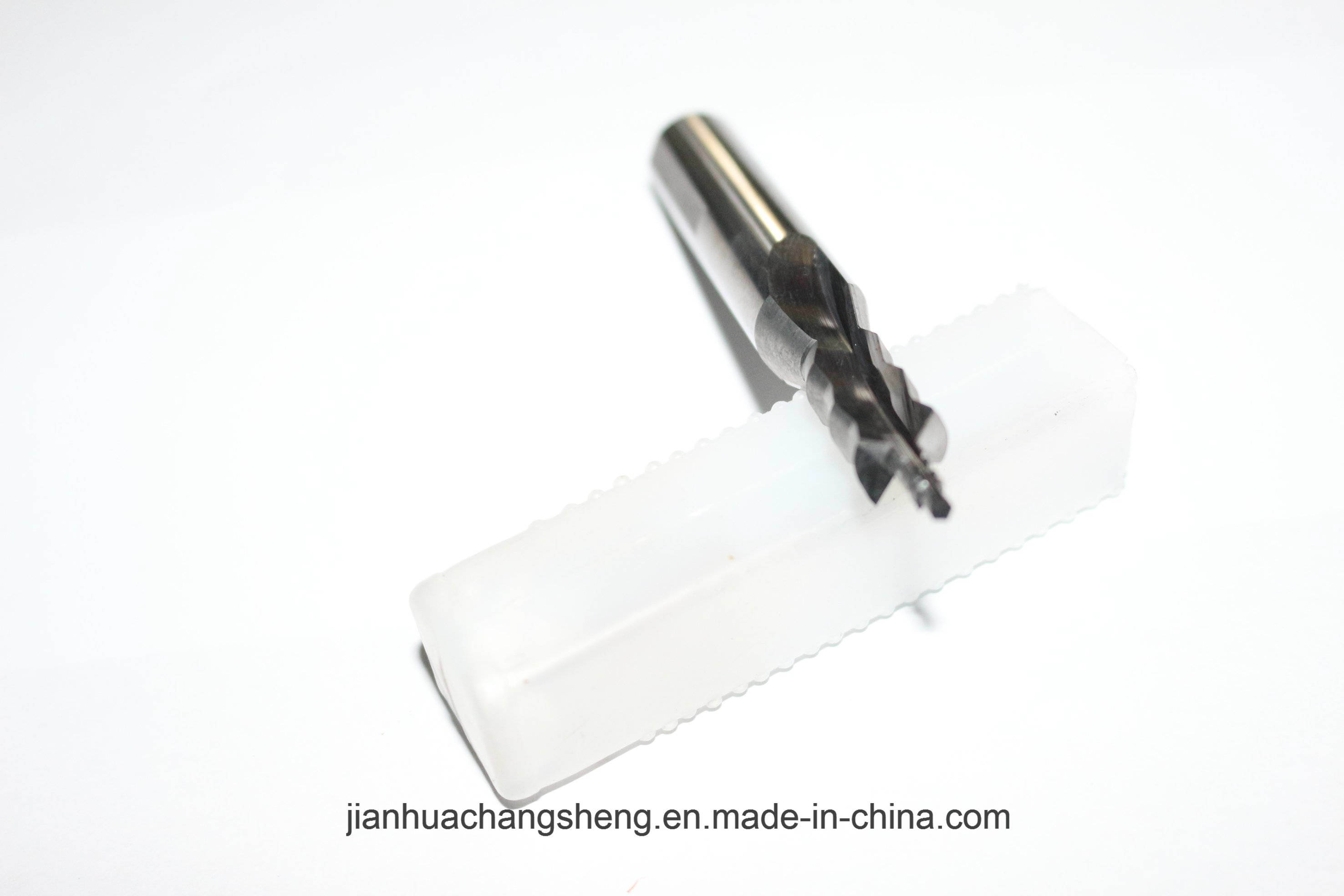

| Profile Cutter Flute: |

1flute 2 Flute 3flute 4flute 5flute 6flute 7flute |

| Flexural Strength: |

2500-6000n/mm2 |

| Length: |

as Your Request From 18-330mm |

| Diameter: |

as Your Request From 3-38mm |

| Usage: |

General Purpose for Cutting All Stuff |

| Controlling Mode: |

CNC System |

| Certificate: |

ISO9001:2008 |

| OEM: |

Yes |

Product Description

| Tool models | End mill, Drill Bits, Reamers, Boring cutters, Taps, Saw Blades, Welding Tools, Customized Cutting Tools, etc. |

| Raw Material | Solid carbide, Tungsten carbide , HSS…(Customized) |

| Coating | TIN, TiALN, AlTiN, TiAIN, etc. |

| Length | 30-200mm (Customized) |

| Diameter | 3mm-40mm (Customized) |

| HRC | 45/55/60/65 Degrees |

| Controlling mode | CNC |

| Usage | General High Speed Cutting

Used On CNC Lathe

Used in special industrial applications such as drilling and reaming |

| Processing material | Alloy steel, titanium alloy, nickel base alloy, steel, stainless steel, quenched and tempered hardened steel, non-ferrous metals, etc. |

| Application | Automotive, aviation, aerospace enterprise, motorcycle engine, diesel engine, carburetor, compressor, mold industry, etc. |

Customized Available,OEM or ODM AvailableOur Advantage1.Professional: Engaged in designing and producing solid carbide cutting tools since 1994, so rich experience and more professional.

2.High quality: Adopted advanced ANCA CNC machine with best raw material from Germany and Sweden, also 100% Zoller measuring and inspecting.

3.Best service: Produce according to your requirement and provide after-sale help if you need.

4.Price: With our own factory, you can get more competitive price from us.

1.Selected high-quality raw materials

1.Selected high-quality raw materials| Grade | YG10X | YG10.2 WF25(Taiwan) | K44 K40 | Sandvik H10F |

| Hardness | HRC50 | HRC55 | HRC60 | HRC65 |

| Grain Size | 0.7um | 0.6um | 0.5um | 0.4um |

| Cobalt Content | 10% | 10% | 12% | 12.50% |

| Flexural Strength | 3320N/mm2 | 4000N/mm2 | 4300N/mm2 | 4300N/mm2 |

100% original raw materials, no recycle2.Super Coating| | TiN | TiCN | CrN | AlTiN | TiSiN | Nano | DLC |

| Hardness(HV) | 2700 | 3000 | 2500 | 3200 | 3600 | 42(GPA) | 3600 |

| Thickness(UM) | 2-6 | 2-6 | 2-6 | 2.5-3 | 3 | 3 | 0.5-10 |

| Oxidation Temp(°) | 600 | 400 | 700 | 900 | 1000 | 1200 | 350 |

| Friction Coefficient | 0.4 | 0.3 | 0.2 | 0.3 | 0.45 | 0.4 | 0.06 |

| Color | Gold | SteelGray | SilverGrey | Black | Copper | Blue | SilverGrey |

Super coating reduce the coefficient of friction, improve the efficency of machines and improve the tools life much.3.Imported CNC machine1.ANCA from Australia

2.Tru Tech from USA

3.Jack Mill from TaiWan province of CHINA

4.Imported Test Machine1.Zoller Genius 3s Zoller TFT-Display

2.SEVEN OCEAN part of Hexagon

5.Strict measurement sequence Five step test1.Test the rod after grinding

2.Test when produce the tools

3.Test all parameter the After the tools finished after CNC machine

4.Test flutes After coating

5.Test the packing before shipping

6.Packaging & Shipping

6.Packaging & Shipping1.Laser brand and dimensions on the body of cutters, print labels.

2.5PCS or 10PCS each group,sealed with air bubble wrap, pack into bigger carton.

3.Marking and Laser brand can be our and yours, or no. All depend on your require.

7.Delivery Time1.For samples, we dispatch your tools in 2-7 workdays.

2.For formal orders, We delivery tools to you in 7-30 workdays, it will depond on your order quantity.

CHANGZHOU JIANHUA CHANGSHENG TOOLS. We are a professional manufacturer of customized high precision solid carbide cutting tools for over 20 years. We mainly produces solid carbide: Drills, milling cutters, reamers, drill reamers, boring tools, hole processing tools, etc., and designs and manufactures all kinds of non-standard cutting tools for users. The company is located in Xixiashu Industrial Park, Changzhou City, 5km away from Changzhou Airport, 3 km away from Shanghai-Nanjing Expressway. The transportation is very convenient.

We got EWC, TUV multiple certifications, our company has the modernized standard Production Workshop, and passed the ISO 9001quanlity system authentication and the QS authentication.

The quality of products is the core competitiveness of the company, so we focus on the control system, from pick the tungsten blanks to design of the product, and CNC grinding programs, every cycle we will impose severe regulations.

In the production of manufacture cutting tools, we priority use the Germany Konrad blanks, Sandvik blanks, and GESAC blanks to do the first working procedure. By the software using side, we choose the ANCA(3D cimulator) system to help us build the model of products, and every kind of item should be stick with a engineering flow sheer, to make sure no mistake happen.

Before deliver to customer, we will use Zollor G 3 surveymeter (German Surveymeter)to detect the products first, when it passed the test will be send to package department to package and make arrangement for the delivery.

Foxcom, Samsung and many Troop supplier was our clients for least 9years, we are looking for opportunity with you from each side of the earth, corporate with us and get the bright future.