| Prod Model: |

HRD-111608 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Certified: |

ISO9001: 2008 |

| First Trial Time: |

20~35 Days After Mould Structure Drawing Confirmed |

| Metal Parts Material: |

SPCC, SUS304, Secc, Al, Cu |

| Stamping Die Material: |

Cr12MOV, SKD61, SKD11, Skh-9, 45#, DC53 |

| Application: |

Car |

| Material: |

Hard Alloy and Steel Bonded Carbide |

| Processing Method: |

Punching and Shearing Mould |

| Technics: |

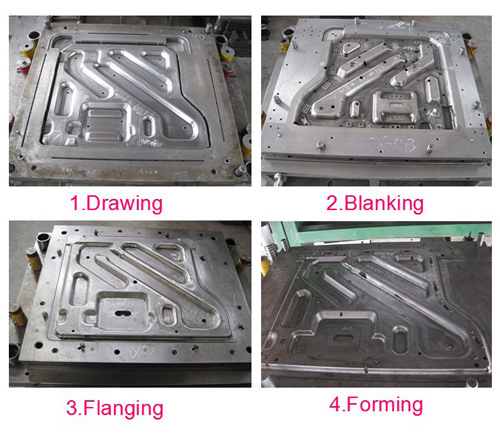

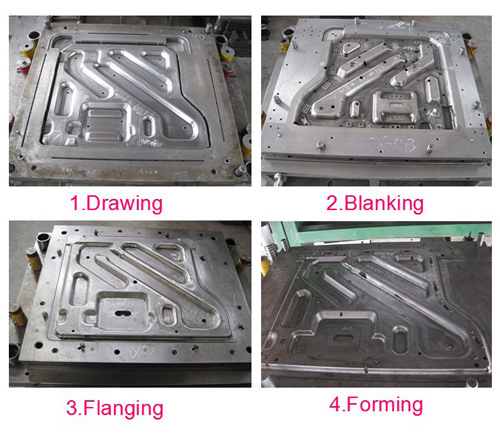

Forming Die |

| Process Combination: |

Progressive Die |

| Manufacturing Technology: |

Computer Technology |

| Mold Cavity Technology: |

EDM Milling |

| Milling Speed: |

High Speed |

| Parts Detection Method: |

Geometric Detection |

Product Description

{Product material}: SUS304, SPCC and so on

{Scope of application}: Auto Progressive die

{Mould Life}: 50~100 shots

{Processing Date}: 35~45 days

{Spare parts}: PUNCH, MISUMI and so on

{Equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T\200T\160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, Sanyo, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements-------------------------

(Packaging: Wooden case)

The first trial success rate is above 95%

{Quotation time}: We will quote in 24 hours after receiving the customer's drawings.

{Data needed to offer}: 2D/ 3D drawing or samples

{Quotation}: Including the accurate price/stage/life and process time.

{The profile}: 2D/3D drawing or samples

{Project Manager}: Concentrate on project tracking and after service

{Engineer}: 30-50 excellent engineers, have many years experience and English communicate well.

{Warehousing and logistics}: The purchase department use EPR system to make sure buying materials in time.

{Fitter technician}: 100-130 experienced workers can meet the customer request of batch production.

{Quality department}: 15 members quality control workers, measuring the mould and parts by CMM and projector.

{Domestic delivery}: Logistics transportation

{Delivery to overseas}: FOB/CIF/DDU by sea shipping or air shipping

Company introduction:

Higrade Group is established on 2003, which is covered an area of 60 acres. We are mainly managing injection mould, stamping die, plastic parts and stamping parts. Our manufacture equipment include Hexagon(Swiss) CMM, Mazak CNC, Sodic EDM, Sodic W-cutting, Depth drill, Carving and so on, and we build many production line for plastic and metal parts. Higrade always pursue high quality with lower cost.

The injection moulds are involved in home appliances, automotive, electronic, medical and other fields. Our mainly customers include Haier, Hisense, Midea, SIEMENS, SANYO, Electrolux, FOTON, GM, WULING etc. We could make different sizes mouls and gain great reputation.

We are specialized in plastic parts from 2011 with home appliance, automotive, electric and etc. Due to our good quality and service, we earn more and more customers, and get long-term cooperation with SIEMENS, HYUNDAI, KIA, and DAMSUNG etc. Our injection machine is 86-160T, 180T, 250T, 380T, 520T, 750T, 1300T and one vertical injection machine; We can test and produce with all sizes of injection mould. To meet the customer request and achieve to production quickly, we assemble the robot in injection machines.

For the metal dies, we are mainly specialized in progressive die, drawing die and compound die. We export to more than 30 countries as Europe, North America, Japan, Thailand, Russia, and South Africa and so on; So we have much export experience. In addition, now we owned the 315T hydraulic press, and many pressess as 200T/160T/110T/80T/40T, they can meet the request of test and batch production.

We obtain the ISO9001: 2008 quality system certificate by SGS from 2007. We build complete organization including top management, marking department, project management, purchase department, engineer department, production department, and logistic department.

| Step | Item | Description |

| 1 | Quotation | We offer you the stamping die and part quotation according to your details (drawing or sample, material, quantity, weight). |

| 2 | Order | If our quotation is competitive, you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample, then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing, we begin to make the moulds, during manufacturing program, we send you mould building progress with pictures every week, for you to know our process. |

| 5 | First trial | We will make the stamping die first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our stamping die quality according to sample. If you need to adjust the product structure, we can help you to change it further. |

| 7 | Delivery | Ship the stamping die after it is completely OK, packed by wooden case. |

Higrade Group is established in 2003, which is covered an area of 60 acres. We are mainly managing injection mould, stamping die, plastic parts and stamping parts. Our manufacture equipment include Hexagon(Swiss) CMM, Mazak CNC, Sodic EDM, Sodic W-cutting, Depth drill, Carving and so on, and we build many production line for plastic and metal parts. Higrade always pursue high quality with lower cost.

The injection moulds are involved in home appliances, automotive, electronic, medical and other fields. Our mainly customers include Haier, Hisense, Midea, Siemens, SANYO, Electrolux, FOTON, GM, WULING etc. We could make different sizes mould and gain great reputation.

We are specialized in plastic parts from 2011 with home appliance, automotive, electric and etc. Due to our good quality and service, we earn more and more customers, and get long-term cooperation with Siemens, HYUNDAI, KIA, and DAMSUNG etc. Our injection machine is 86-160T, 180T, 250T, 380T, 520T, 750T, 1300T and one vertical injection machine; We can test and produce with all sizes of injection mould. To meet the customer`s request and achieve production quickly, we assemble the robot in injection machines.

For the metal dies, we are mainly specialized in progressive die, drawing die and compound die. We export to more than 30 countries as Europe, North America, Japan, Thailand, Russia, and South Africa and so on; So we have much export experience. In addition, now we owned the 315T hydraulic press and many presses as 200T/400T/160T/110T/80T/40T, they can meet the request of test and batch production.

We obtain the ISO9001: 2008 quality system certificate by SGS from 2007. We build complete organization including top management, marketing department, project management, purchase department, engineer department, production department, and logistic department.