| Prod Model: |

dk-investment casting |

| Sample Time: |

20days |

| Production Time: |

30days |

| Service: |

OEM/ODM |

| Size: |

Customize |

| Unit Weight: |

0.01kg-100kg |

| Casting Type: |

Lost Wax Casting |

| Casting Method: |

Directional Crystallization |

| Material: |

Stainless Steel |

| Surface Preparation: |

Polishing |

Product Description

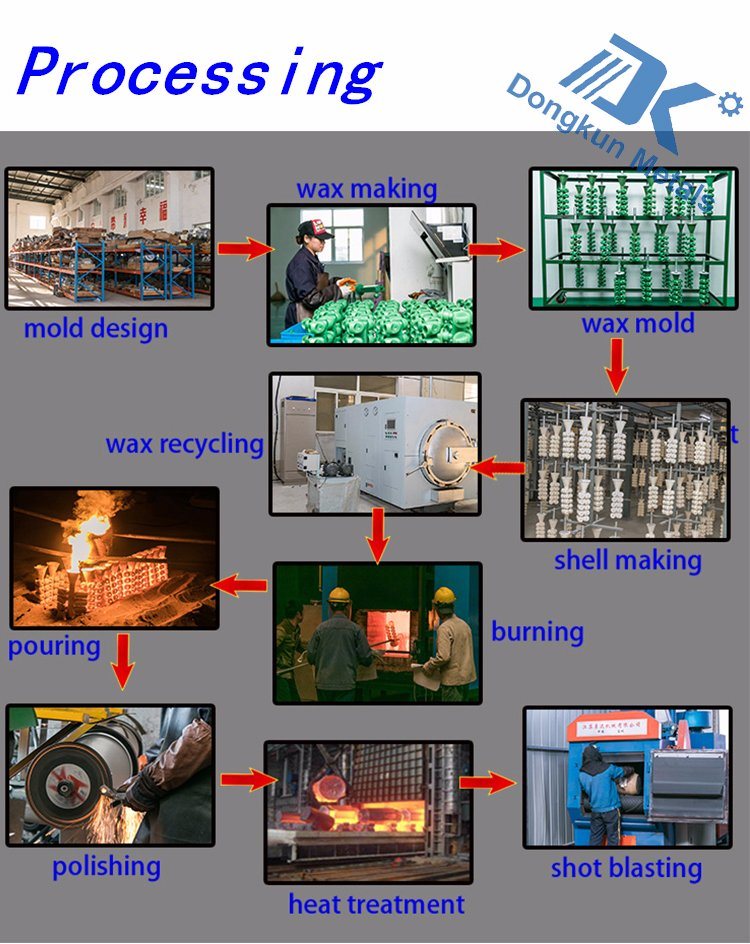

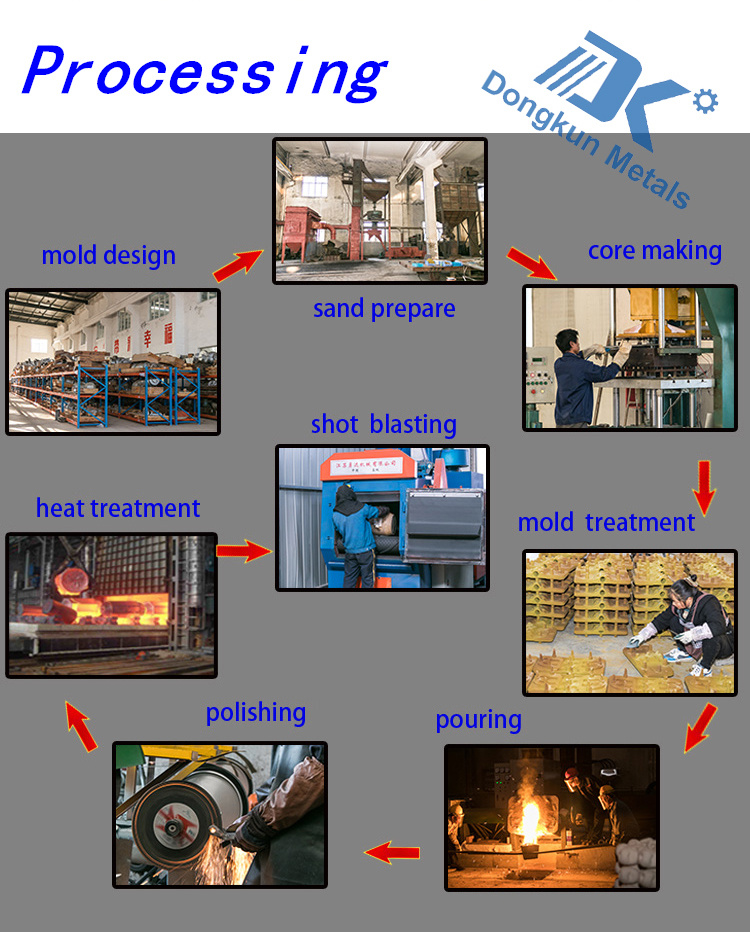

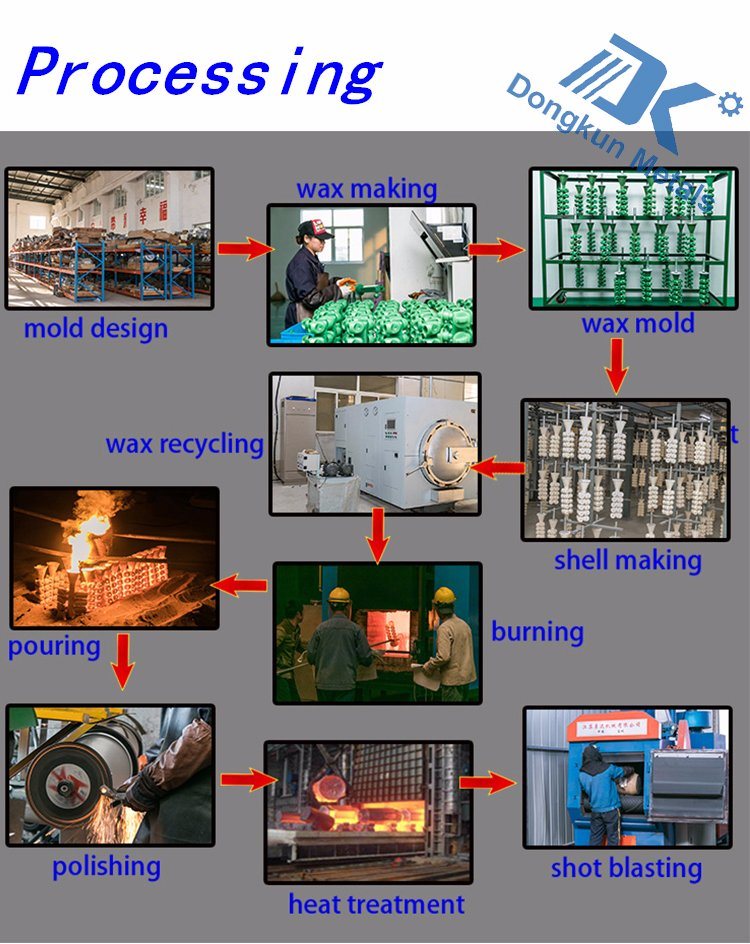

steel precision casting for machinery partsProduct basic description| Process | lost wax Casting, other process can be customized. |

| Material | Alloy steels, Carbon Steel , Stainless steel, Malleable iron , Grey iron, Ductile iron Aluminum, Bronze etc. |

| Unit Weight | 0.1kg-100kg |

| Finish | Plain,Nickel Plating , Chrome Plating or Polishing |

| Application | Automotive ,Mining, Railway, Construction equipment,Mining etc |

| Quality Control | CMM, Projection Machine, spectrometer, Hardness tester, Tensile tester etc. |

| Certificate | ISO 9001:2008 |

| Standard | ASTM,DIN,ISO,BS,JIS |

Our products are mainly used in valve industries.We can provide many kinds of casting parts/stamping parts/machining parts and forging parts.

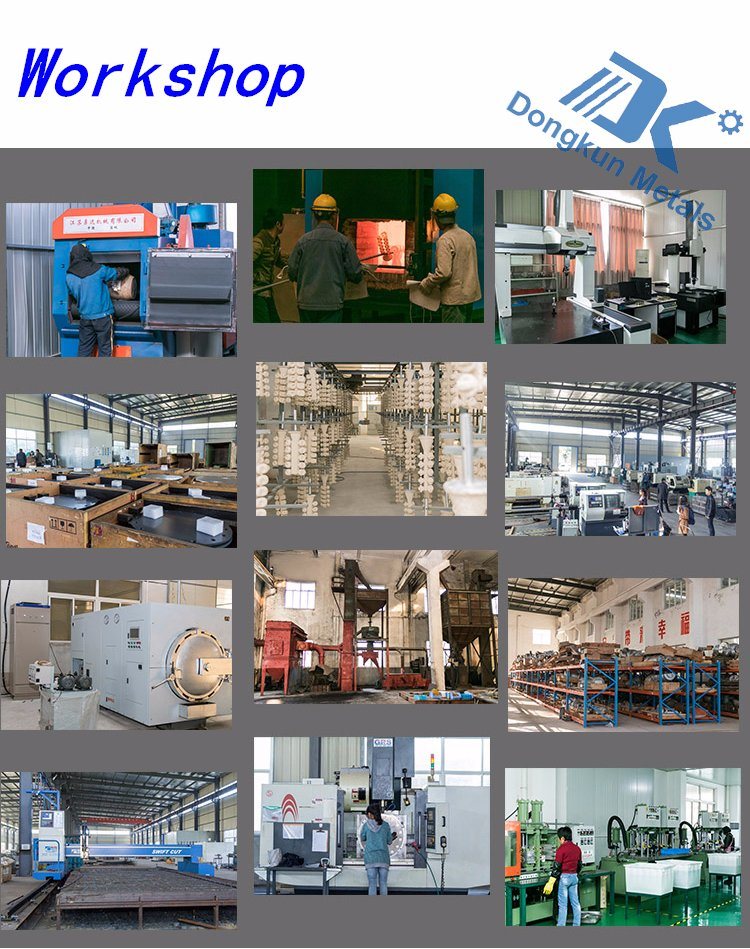

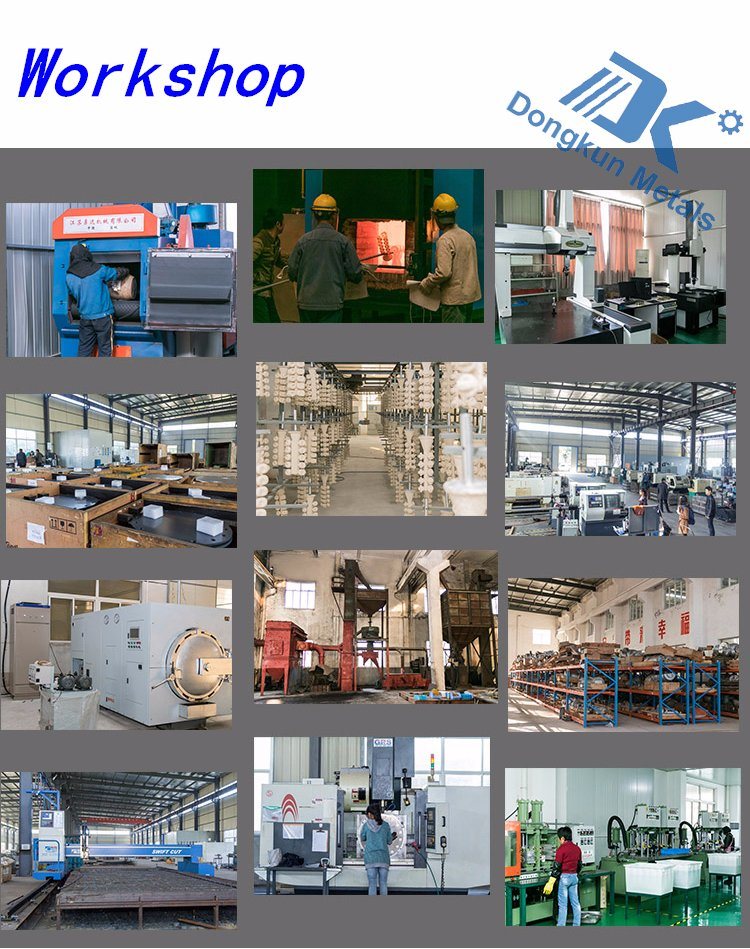

1. Aluminum casting, sand casting, die casting, gravity casting, high pressure die casting, low pressure die casting, forging, stamping, machining.

2. Applied software for specification drawings: Auto CAD, Solidworks.

3. Precision machining: CNC, milling machine, drilling machine, numerical lathe, all types of lathe.

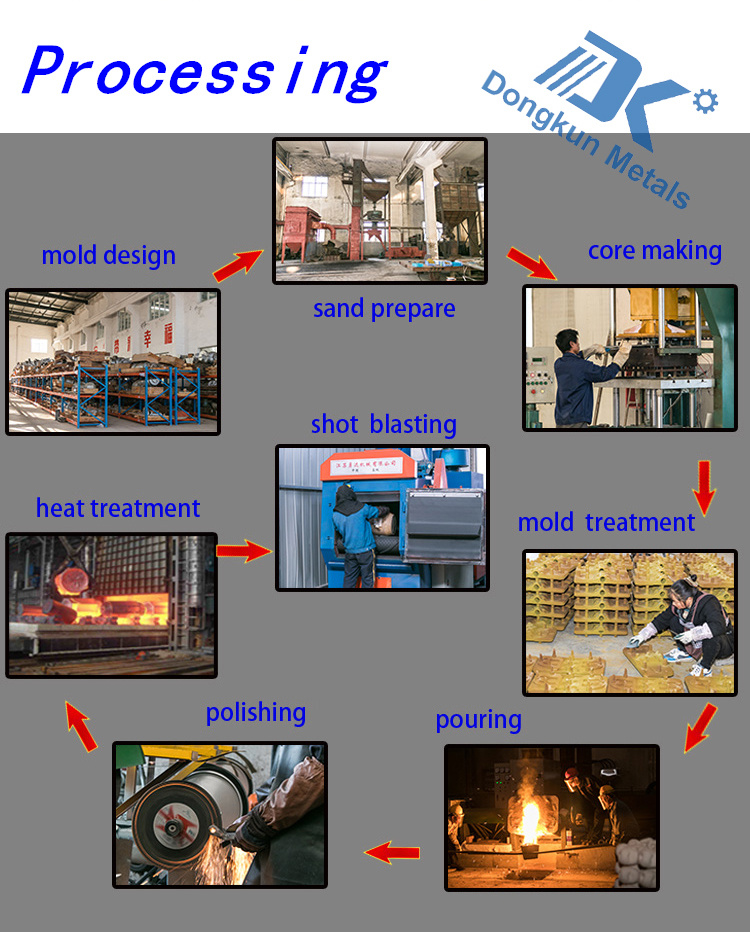

4. Surface finish process: polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing.

5. Good quality and strict delivery time.

We can read CAD, E-drawing and Pro-E files and use CAD as assistant design for customers. Staffs of DK metals are composed of experienced engineers, metallurgist and professional salesmen with engineering background.DK has strong quality assurance capability. We have in-house CMM, Spectrometer, 2-D projection machine, Roughness tester, Hardness tester, Thickness tester, NDT inspection machines and dozens of normal inspection tools.

We deeply knows quality is key problem of engineering products. DK is an ISO9001:2008 certified company. Our factories are mostly ISO9002, QS9000 or ISO/TS16949 certified. Except for internal control of our factories, DK metals is also involved in QC process of products that we developed. This has ensured our products to earn great reputation from our customers.

DK metals is a professional parts engineering company. We have 13years experience in casting /forging and machining. There is a casting foundry and machining factory own to us. We can provide many solutions for different parts with different processes.

DK Metals has done many successfully projects in different industries such as: Automotive, aeronautic railway, machinery and mining industry.

We always put quality on the first and be strict with all processes. There is a rigorous product quality testing before any delivery. What such we have done is just to ensure DK never through any products troubles to our customers.

There is a technical staff from engineers and production to salesman and quality control. We plan to build more factories to realize more processes even though we have many competitive cooperation factories now. We believe only grasp basic production in our own hand can we create more value.

DK Metals earned great reputations from our worldwide customers. We think we will have more approval in future. Don't forget to give us an opportunity, we will return you a surprise.