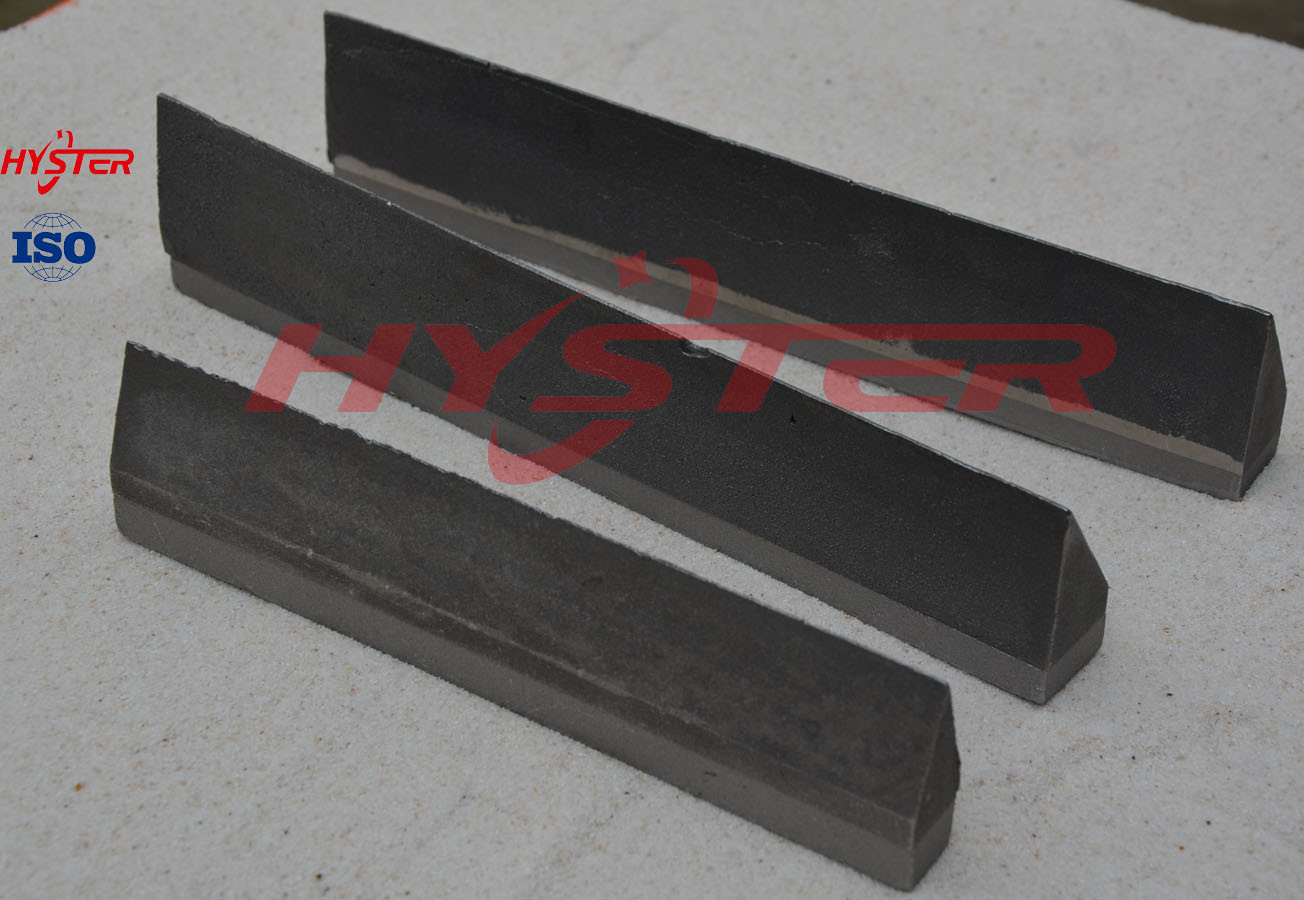

Sugarcane Cutting Knife Edge

| Price: |

US $ 5-11.5kg |

| Min Order: |

100kg |

| Pay Type: |

L/C,T/T,Western Union,Paypal,Money Gram |

| Name: |

Knife Edge |

| Other Name: |

Cutting Knife Edge |

| Material: |

High Chrome Cast Iron&Mild Steel |

| Hardness: |

63HRC/700bhn |

| Tensile Strength: |

630MPa Min |

| Shearing Strength: |

250MPa Min |

| Micro-Structure: |

Carbide+Martensite+Retained Austenite |

| Application: |

Sugar Mill |

| Fuction: |

Crushing, Shredding |

| Advatage: |

Excellent Wear Resistance |

| Casting Method: |

Sand Casting |

| Casting Form Material: |

Metal |

| Casting Metal: |

Cast Iron |

| Casting Form Usage Count: |

Disposable |

Product Description

Sugarcane Cutting Knife Edge

Knife Edge1)Products: Cutting Knife Edge2)Materials: high chrome cast iron(ASTM A532 15/3CrMo, Wear Portion) vacuum brazing onto High impact Mild steel

3)Chemicals:| C | Cr | Mn | Mo | Cu | P | Si | S | B. V. Nb |

| 2.5-3.5 | 15-18 | 0.5-1.0 | 0.5-2.5 | 0.5-1.0 | 0.02max | 0.5-1.0 | 0.02max | 0.1-0.5 |

4)Mechanical Property:A) Tensile Strength 630Mpa Min. B) Shearing Strength250Mpa Min. C) Hardness63 HRC/700BHN Min.5)Micro-structureCarbide + Martensite + Retained AusteniteThe Carbide Content is about 35% 6)Typical Size for cutting knife edge| Type | Item No. | Size | Dimension(mm) | N.W. |

| (mm) | A | B | C | D | E | (kg) |

| 1 | HK1 203-16 | 203x16x50 | 203 | 16 | 38 | 12 | 50 | 0.9 |

| HK1 203-19 | 203x19x50 | 203 | 19 | 38 | 12 | 50 | 1.1 |

| HK1 203-22 | 203x22x50 | 203 | 22 | 38 | 12 | 50 | 1.3 |

| HK1 203-25 | 203x25x50 | 203 | 25 | 38 | 12 | 50 | 1.5 |

| HK1 305-26 | 305x16x50 | 305 | 16 | 38 | 12 | 50 | 1.4 |

| HK1 305-19 | 305x19x50 | 305 | 19 | 38 | 12 | 50 | 1.6 |

| HK1 305-22 | 305x22x50 | 305 | 22 | 38 | 12 | 50 | 1.9 |

| HK1 305-25 | 305x25x50 | 305 | 25 | 38 | 12 | 50 | 2.2 |

| 2 | HK2 203-16 | 203x16x50 | 203 | 16 | 38 | 12 | 50 | 1 |

| HK2 203-25 | 203x25x62 | 203 | 25 | 50 | 12 | 62 | 1.7 |

| HK2 305-25 | 305x25x56 | 305 | 25 | 40 | 16 | 56 | 2.5 |

| 3 | HK3 203-19 | 203x19x50 | 203 | 19 | 38 | 12 | 50 | 1.6 |

| HK3 203-25 | 203x25x50 | 203 | 25 | 38 | 12 | 50 | 2.1 |

| HK3 203-28 | 203x28x50 | 203 | 28 | 38 | 12 | 50 | 2.3 |

7)OEM is welcomed, can also be customized as per the clients specific need8)Certifications: ISO9001:20089)ApplicationsSpecifically designed for the sugar industry utilising a sharp edge for maximum shredding efficiency10)Some of our wear resistant material products and services:--Wear plates, wear liners --Chocky bars , wear buttons, Bolt Protectors --Wear blocks, wear bars--Carbide Chrome Overlay Wear Plate--Hammer tips, Knife edges, Grid Bars for sugarcane, mining and steel industry--Grizzly Bars, Roll Bars, Rockbox Liner--Skid Bars, Bolt Portector--Custom made wear liners --Bucket repair and protection --Full Fabrication services --Sugar mill hammer tips --Drilling, milling or machining --Casting/Investment casting --Fast service and timely delivery11)More DescriptionUsed primarily in the sugar cane industry, the unique shape has also been successfully used as grouser bars and in blade cutting edge protection.Easy to install and change. These Knife Edges will increase production and cutting efficiency.12)Contact:

Bonnie Deng, Cell: 86-189-4254-3248

Hunan Hyster Material Technology Co., Ltd., formerly name is hyper casting parts Co., Ltd., is an independent international supply, design and engineering company, in operation since 1995, we specializes in high quality of wear products.

Hyster offer our clients a wide range of wear products and professional wear solutions. We also welcome custom made one off's and consumables.

Some of our products and services:

--Wear plates, wear liners

--Chocky bars and wear buttons

--Wear blocks, wear bars

--Custom made wear liners

--Bucket repair and protection

--Full Fabrication services

--Sugar mill hammer tips

--Drilling, milling or machining

--Casting/Investment casting

--Fast service and timely delivery

With strict management system and strong technical base, Hyster Corporation is committed to provide high-quality products and services for the fields of Mine and Mining, Quarrying, Electrical power, Cement, Sugar, Aviation, Marine, Railway, Engineering plant and Petroleum machinery industries.

Quality is very important to the development of Hyster Corporation. The company strictly operates according to ISO9001: 2000 quality management system. Over 95% products have been sold to Australia, Canada, South Africa, Brazil, America, Chile, Indonesia, Argentina, Thailand, Mexico, Russia, Holland, as well as many other countries and areas.

Moreover, breaking out of the traditional practice that only provide OEM products, our company has created the new sales concept whose main points are providing solutions, terminal products and customer services, which enables us to better fulfill customer specifications in a positive manner.

Please contact us directly with any questions or inquiries!