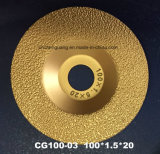

Product Description

Vacuum brazed diamond saw blade Main Features1)Best suitable for Grinding Marble, Sandstone and ceramic tiles

2)Suitable for both Wet Cutting and Dry Cutting.

3)High degree of exposed diamond grains and sharp cutting.

4) Characteristic of safety , longer life, reducing Spark, Lower noise and Environment Friendly Compared

with Resin Tools

Vacuum Brazing is a material jointing process that directly bonds diamond to the blade. It is a three steps process that creates a bond which is significantly stronger that other joining methods.Vacuum brazed diamond blades are made with a much higher quality process than typical sintered or laser welded diamond blades. Blades mostly have a mixture or diamond matrix of different materials that are bonded onto the steel core of the diamond blade. With the vacuum brazing process, the segments are coated in diamonds. Instead of regular diamond blades that wear away and almost re sharpen themselves, vacuum brazed blades use the exterior of the segment of the cutting edge.

Product ApplicationThe Vacuum Brazed Diamond Saw Blades are bestly used for cutting Marble , Granite , Ceramics and Bluestone in Stone Processing , cutting Concrete with rebar in construction industry, Cutting Metal and Fiber Glass.

The Vacuum Brazed Diamond Grinding Disc are widly used for grinding Marble, Ceramic Materials and Fiber Reinforced Plastic.

The Vacuum Brazed Diamond Grinding Wheel are suitable for grinding metal in Foundry Industry.

Application Of diamond disc for cut glass

1, Use for cutting and grinding ordinary flat glass, frosted glass, sandblasted glass, embossed glass, wired

glass, hollow glass, laminated glass and glass block, diamond grit 80 -120. Cutting fast; the blade edge is not

easy to be broken.

2, Use for cutting and grinding granite, basalt, limestone, dolomite, sandstone, marble and other stone,

diamond grit 36- 60. Cutting fast; the blade edge is not easy to be broken.

3, Use for cutting and grinding porcelain, wall brick and floor tile, sanitary ware, ceramic handle, silicate

products and silicon wafer, diamond grit 36-60. Cutting fast; the blade edge is not easy to be broken.

4, Used for cutting and polishing of other metal products, such as aluminum, stainless steel, etc.

Contact with us

Ms. Una Hou

Changsha Chenguang Machinery&Electric Equipment Co. Ltd

Add: No123, ShaoShan Nan Road, Changsha, Hunan, China

Tel: +86-731-84613726 +86-731-83521833

Fax: +86-731-84613826

Mobile : +86 15200938145

Chenguang machinery & Electric Equipment Co. Ltd specialized in development, production, and marketing of ultra-hard materials.

We started to provide high quality synthetic diamond to domestic diamond tool manufacturers since1993. We utilize a wide range of advanced production equipment and test instrumentation in an environment using strict quality control procedures for all our products. As a diamond supplier; We provide a wide range of diamond products and solutions for many well-known Chinese enterprises. Among these enterprises are more than 20 well-known enterprises who have enjoyed at least 10 years with us; We are proud to mention that our products are routinely exported worldwide since 2010, the stable quality and professional service is well appraised by huge users.

Our main superhard matierial products include: Synthetic diamond, Diamond saw blade, Diamond Drill bit, welcome friends from home and abroad to cooperate with us and create a brilliant future.