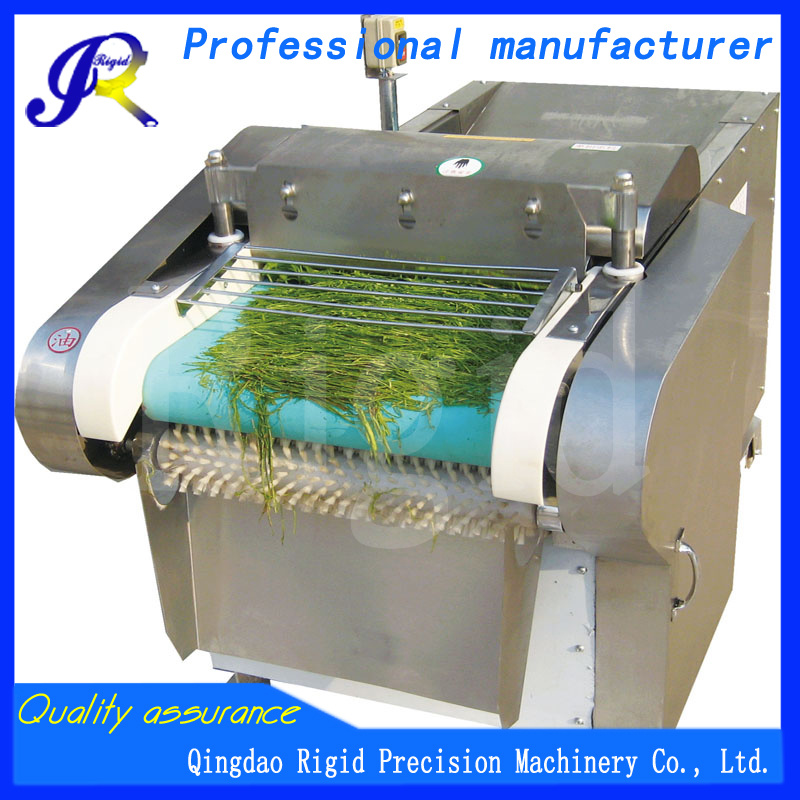

Vegetable Processing Machine Automatic Cutting Machine Cassava Cutter

| Price: |

US $ 876-987sets |

| Min Order: |

1sets |

| Pay Type: |

L/C,T/T,D/P |

| Prod Model: |

Rd-C/180316 |

| Material: |

304 Stainless Steel |

| After-Sale Maintenance: |

One Year Warranty, Lifetime Maintenance |

| Type: |

Cutter |

| Voltage: |

380V |

| Power: |

0.75KW |

| Customized: |

Customized |

Product Description

Vegetable cutting machine/Reciprocating vegetable cutter

Material: 304 Stainless steel

Kelp cutters thick stainless steel plate material used, the use of food grade conveyor belt, so kelp processors use more health, safety, security.| Art.No. | Material | Power | After-sale maintenance |

| Rd-C/180316 | 304 Stainless Steel | 0.75kw | One year warranty, lifetime maintenance |

Using the Operation

1. Before the first working test cut, cut vegetables to observe the specifications and requirements specifications are the same, or should adjust the length of the slice thickness or vegetable, the normal work to meet the requirements.

2. Install vertical knife

2.1The vertical knife set knife on board, the lower edge is parallel with the fixed contact blades, fixed blades on the turret pin fastening nut cutter, you can remove the fixed blades .

2.2 Other shredder installation, vertical knife: After the first rotation adjustable eccentric, so turret line to the lower dead point, and then lifted up 1/2 mm turret so that the vertical blade contact with the conveyor belt, the fastening nut the vertical blade fastened to the turret. Description: Overhead Lift height master of their own based on the cut vegetables. If the overhead lift height is small, there may not even vegetable knife, if the overhead lift height is too large, it is possible to cut bad conveyor belt.

3. chopping length adjustment:

control the length of the value observed on the display panel and length requirements are consistent growth by increasing the length of time the button, press the down button to reduce the length of time.

Other Shredder adjustment:

Turn the adjustable eccentric, loosen the screws fastening rod, cut filaments movable fulcrum, from outside to inside; movable fulcrum cut thick wire, from the inside out, tighten the adjustment after a good tune screws.

The company consists of casting companies, installation companies, scientific research center and machining center, etc., have a mature production line equipment, mainly for all kinds of fruits and vegetables, food, agricultural products finishing - cleaning - cutting - blanching - cooling - dehydration - drying - crushing - packaging; Main line pepper processing line, clean vegetables processing line, garlic processing line, pickles(kimchi)processing lines, all kinds of fruits and vegetables, mushroom, seafood, agricultural products, nuts, drying lines, etc. Also or according to the customer's requirements to carry out the design of the food complete process, production and production.

Plastic brand image - a quality brand, my company is willing to "innovation, gratitude, responsible, sincere, communication" and the broad masses of customers at home and abroad to cooperate and work together to grow together and development, mutual win-win; The principle of pursuing reality, innovation, mutual benefit and all the parties join hands to create brilliant future together.

We supply different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will reply you as soon as possible. We stick to the principle of " Quality first, service first, continuous improvement and innovation to meet the customers" For the management and " Zero defect, zero complaints" As the quality objective. Qingdao Rigid