| Prod Model: |

CB002 |

| Size: |

According to Your Request |

| Application: |

Mold and Pattern Making, Die Sinking, |

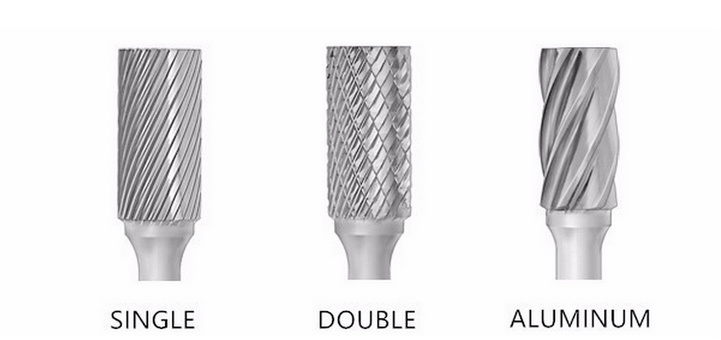

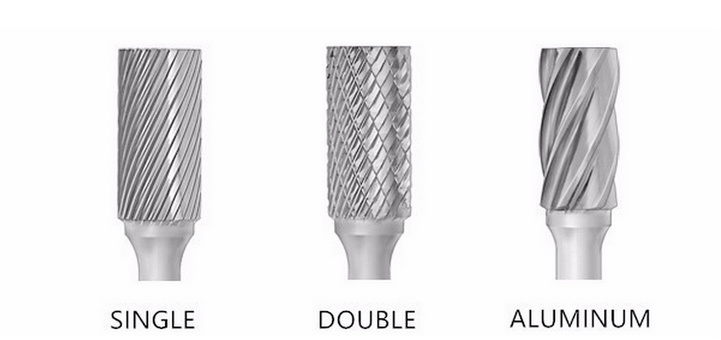

| Tooth Type: |

Standard Cut/Double Cut/Diamond Cut/Co |

| Production Process: |

CNC |

| Type: |

Carbide Burrs |

| Material: |

Carbide |

| Processing Methods: |

Milling File |

Product Description

Application Tungsten carbide burr is used widely in the shipping construction, auto engine porting and foundry fabrication. With its high rotating speed and hardness, it can machine a lot of different materials like cast iron, carbon steel, alloy steel and non ferrous material. High life service of product is warranted for virgin and excellent raw material which is one of most critical factors to the tools' life.

Material

| Tungsten Carbide |

| Sizes | Shank dia:3mm,4mm,6mm;blade dia/blade length/overal length:standard/as request |

Processing hardness

| HRA≥85

|

| Grinding surface | Ral.6 |

Abrasive processing

| Process metal/nonmetal products with hardness less than HRC70

|

| Usage |

The carbide alloy rotary file use is extremely widespread,appies in the mold processing manufature .Machine parts bevel edge ,inverted round and trench processing ,the clean-up casting ,foreiging,weldment's edge,burr and welded joint;pipeline,impeller passage's light entire processing ,metal and nonmentallic naterial (bone jade stone )industrial art carving .

|

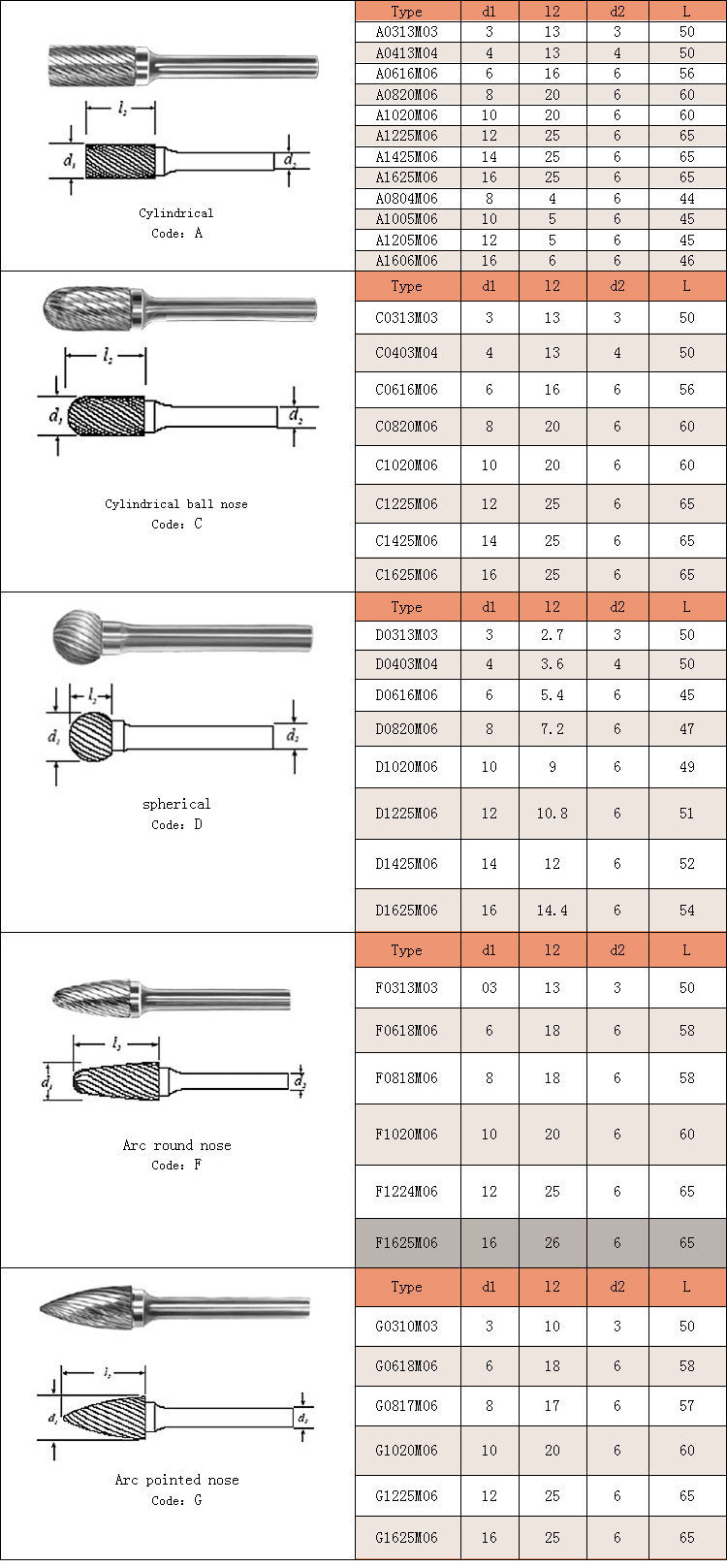

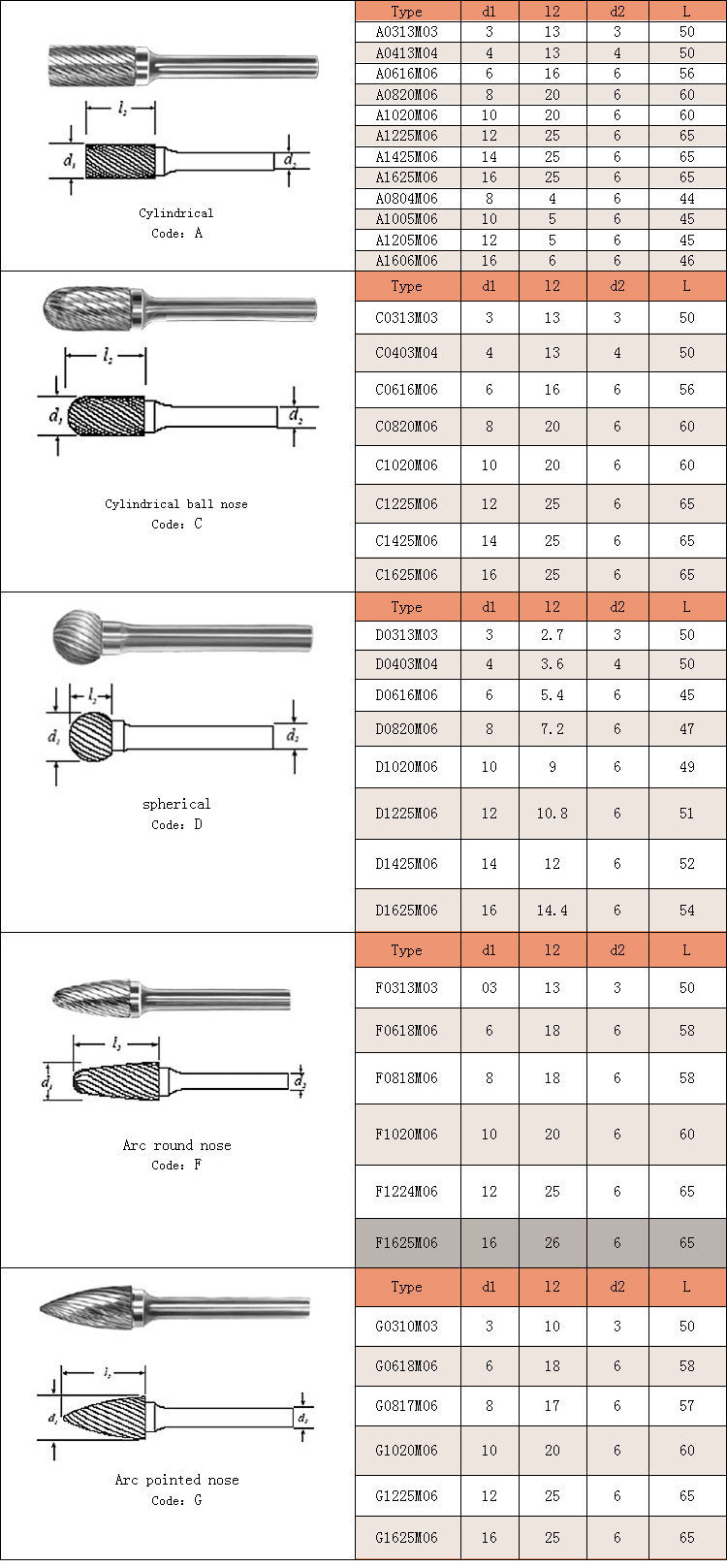

| Shape | Cylinder, cylindrical ball nose, spherical, oval, arc round nose, arc pointed nose, torch-shaped, 60°C conical, 90°C conical, Taper with round top,conical pointed nose,inverted conical, cone flat nose, Dise type with arc edge,Concace arc shape, columni form with half round nose, Dise type of 90 degree, etc

|

Specifications| Name | Type | Cut | Material | Product Process | Head Hardness | LOGO |

| Cylindrical | A | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Cylindrical End Cut | B | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Cylindrical Radius End | C | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| BALL SHAPE | D | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Oval | E | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

Tree Shape

Radius End | F | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Tree Pointed Ends | G | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

Flame

Shape | H | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| 60°Cone | J | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| 90°Cone | K | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Taper Radius End | L | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Cone | M | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Inverted Cone | N | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Disc Type | W | Standard/Single/Double/aluma | Tungsten carbide/YG7/TCT | CNC | 90-91HRA | available |

| Grades of Carbide Tungsten Burr |

| China Grade | ISO grade | Density(g/cm3) | Hardness(HRA) | TRS(Mpa) |

| YG6 | K20 | 14.95 | 91 | 1800 |

| YG6X | K10 | 14.95 | 92 | 1800 |

| YKM6A | K10 | 14.95 | 92.5 | 1800 |

| YG8 | K30 | 14.7-14.8 | 90 | 1950 |

| YT5 | P30 | 13 | 90.8 | 1900 |

| YT14 | P10-20 | 11.5 | 91.5 | 1500 |

| YT15 | P10-20 | 11.3 | 91.8 | 1450 |

| YW1 | M10-20 | 13.1 | 91.5 | 1600 |

| YW2 | M10-20 | 13.1 | 91 | 1600 |

| YS25 | P25 | 12.8 | 91.5 | 1900 |

| YC30S | P30 | 12.8 | 91 | 2000 |

| ZP35 | P35 | 12.8 | 91 | 2000 |

| YC40 | P35 | 13.2 | 90 | 1850 |

Other specification is also available according to your requirements. (OEM, ODM )

Pls. contact us freely for more information, I will reply you ASAP!

Hope you will enjoy a comfortable cooperation with us!

Shipping

Shipping 1. FedEx/DHL/UPS/TNT for samples

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

How to Contact Us?

Send your Inquiry Details in the Below for sample, Click "Send" Now!

Why Choose Our Products?

1) ISO 9001,Gold Supplier certificated

2) Monthly Production Capacity -- 1 Million Pcs

3) All goods examined before delivery by 10 QC staff

4) Prompt Reply Within 12 Hours

Xuzhou Perfect Industry Technology Co., Ltd is a professional Manufacturer of high quality of

Different kinds of cutting tools, Including drill bit, screw tap, screw dies, end mills, reamers, saw blade,

etc.

With 6 years' development, we have a professional technical team; Advanced machinery. A professional

Engineering team is dedicated to ensuring The prompt delivery of our new products. In order to win a

Large market share, We regularly introduce new products and upgrade older series.

We also provide OEM/ODM services according to customers' requirements. Our strength consists of

Innovation, high-quality products, superior services And competitive prices. Please contact us if you are

Interested in any of our Product.

Xuzhou Perfect Industry Technology Co., Limited relies on continous technical improvement and

Persistent high performance products. Therefore, the long-term development guideline of the company

Is emphasizing on the quality and technical investment.

The company owns advanced CNC numerical control system production line and treatment

Technique, what is more, it also has advanced testing facilities with material analysis, mechanics

Check, numerical control cutting check, etc.

Our products are favored by clients in Europe, America and other over 30 countries. We have been

Becoming the leading manufacturer wordlide in capacity and technology.