| Prod Model: |

Longterm Machinery |

| Productivity: |

220-260 PCS/Hr |

| Working Air Pressure: |

<=0.6MPa |

| Power1: |

12kw AC380V 50Hz |

| Power2: |

1kw AC220V 50Hz |

| Workstation Quantity: |

12 |

| Testing Quantity: |

12 Cylinders at The Same Time |

| Cylinder Thickness: |

2.65-4mm |

| Cylinder Size: |

6kg, 12kg, 25kg, 48kg, or Customized |

| Cylinder Diameter: |

250~800mm or Customized |

| Customized: |

Acceptable |

| Certification: |

CE |

Product Description

Automatic online hydro testing machine

Technical Data:

The integration and automatic YS-8/12 LPG cylinder hydraulic testing equipment is special used for LPG cylinder hydro testing.

The workstation of the equipment is 12, the design improve the productivity by testing the 12 cylinders at the same time.

1. Productivity: 220-260 pcs/hr

2. Working air pressure: ≤0.6MPa

3. Power: 12KW AC380V 50Hz, 1KW AC220V 50Hz

4. Water quantity for testing: ≥2m3 water tank or water pool

The water filling part equips with 1 set roller conveyor line, 1 set water filling device, 1 set cylinder block device, 3 sets locator device.

Water pressure testing area equipment include one roller conveyor line,one set water pressure testing device, 1 set resistance of bottle opener, locator 3 sets. Automatic lpg gas cylinder production lineMachine list:

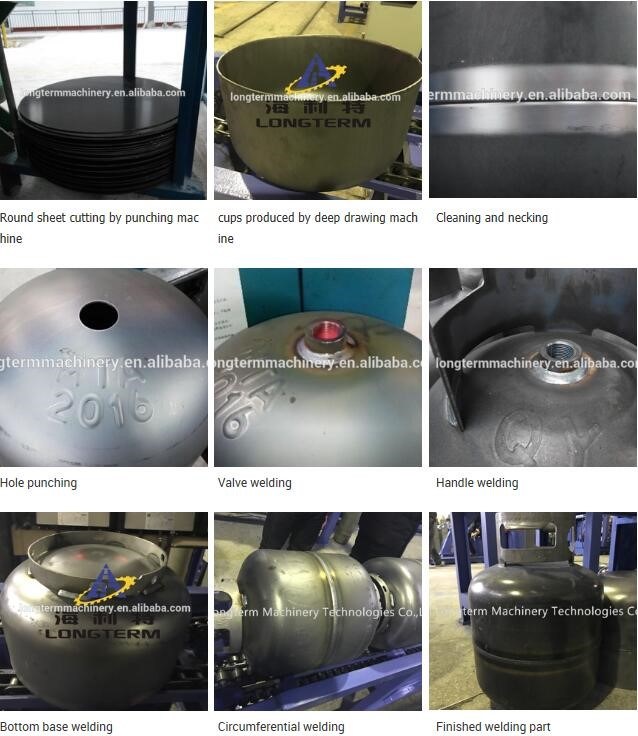

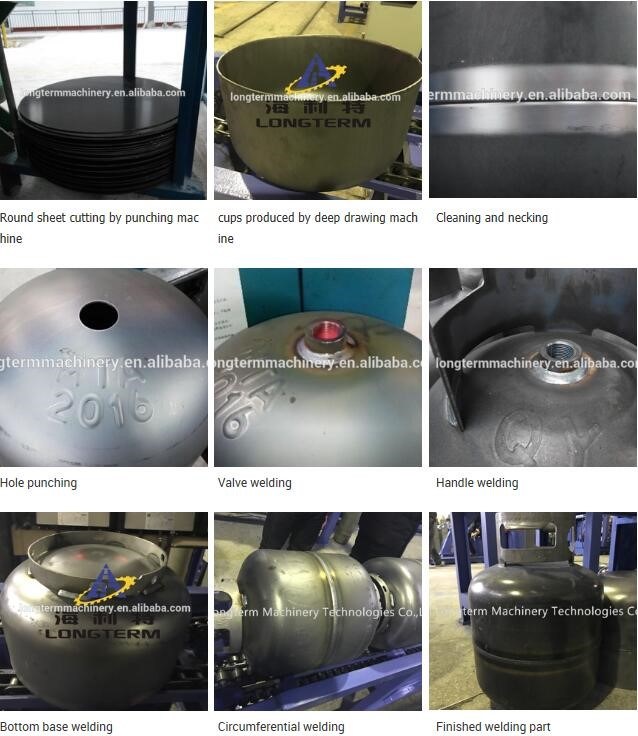

Automatic lpg gas cylinder production lineMachine list:| No | Machine name |

| 1 | Mechanical decoiler,straightening and blanking line(with scrap shearing machine) |

| 2 | Deep drawing machine |

| 3 | Auto flushing machine for deep drawn heads |

| 4 | Automatic trimming &polishing machine |

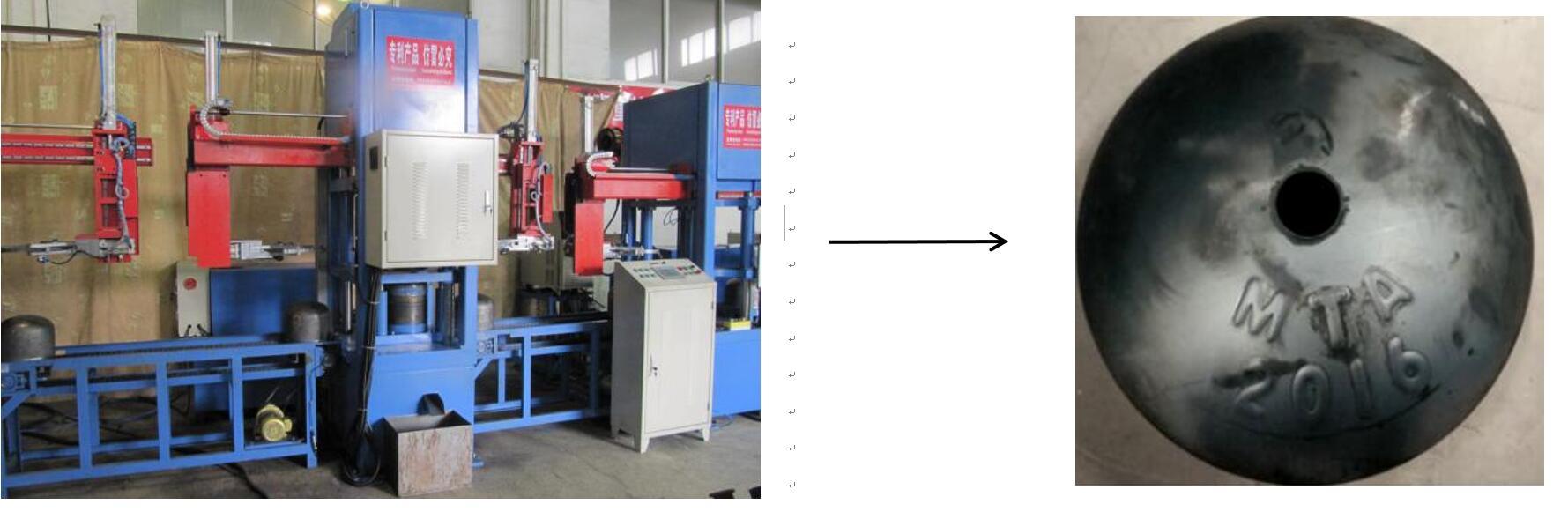

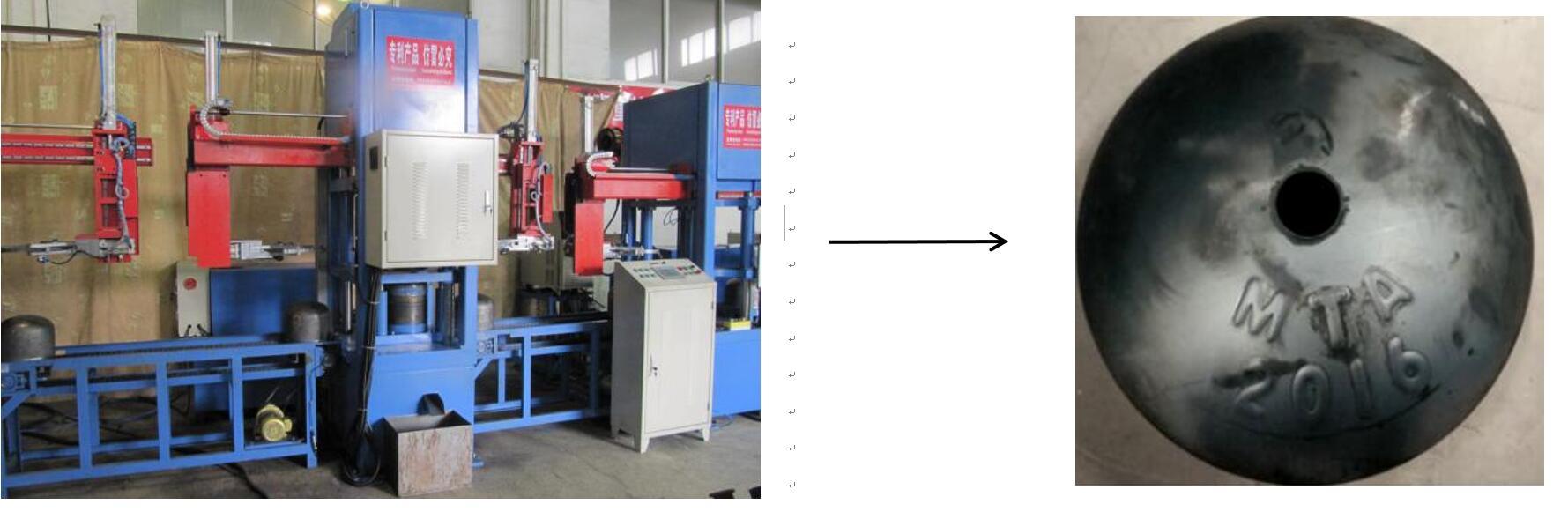

| 5 | Automatic hole punching &logo making machine |

| 6 | Automatic socket welding machine |

| 7 | Automatic handle welding machine |

| 8 | Lower end dish trimming and polishing machine |

| 9 | Lower end dish automatic joggling machine |

| 10 | Automatic bottom base welding machine |

| 11 | Assembly and spot welding machine |

| 12 | Circumferential welding machine |

| 13 | LPG gas furnace(heat treatment) |

| 14 | Automatic online hydro testing machine |

| 15 | Drying oven |

| 16 | Shot blasting machine |

| 17 | Zinc metalizing machine |

| 18 | Powder coating line or Liquid Painting Line |

| 19 | Valve mounting machine |

| 20 | Air leakage testing machine |

| 21 | Printing machine |

| 22 | Handle decoiler &straightening and cutting line |

| 23 | Handle hole punching machine |

| 24 | Hydraulic Presser-letter stamping(Optional) |

| 25 | Handle end bending machine(Optional) |

| 26 | Hydraulic coding machine |

| 27 | Handle rolling machine |

| 28 | Handle top R forming machine |

| 29 | Handle low R forming machine |

| 30 | Vertical Bottom base rolling machine |

| 31 | Double welding position welding fixture |

| 32 | Base forming machine |

| 33 | Hydraulic Precision sheet shearing machine(33KG only) |

| 34 | Sheet rolling machine(33KG only) |

| 35 | Automatic Seam Welder(33KG only) |

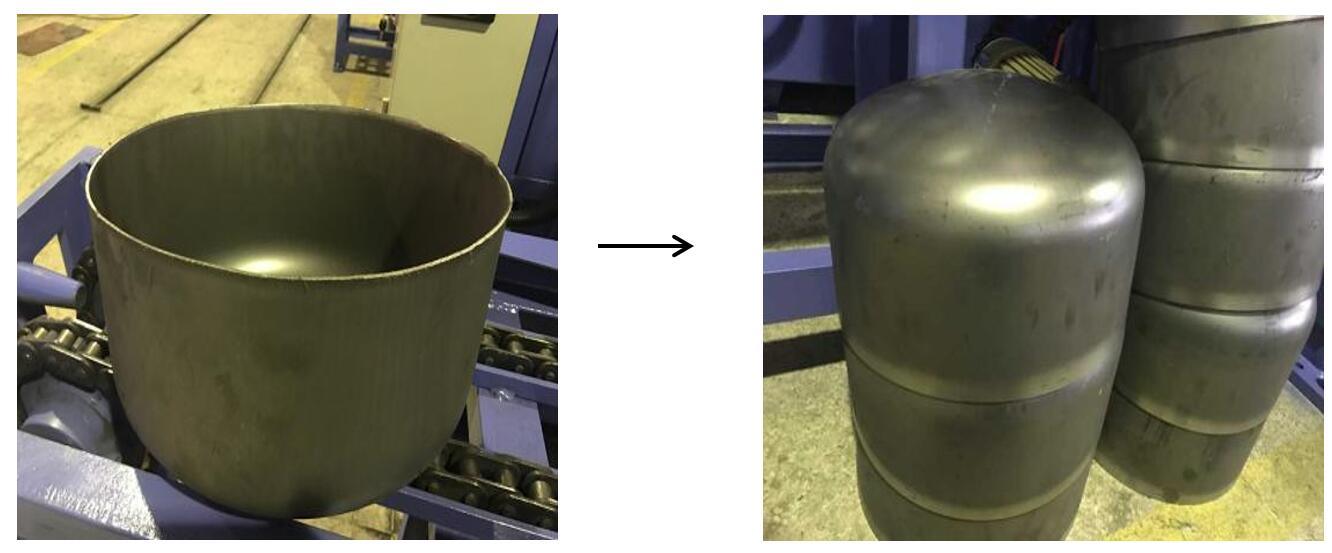

Production Process Mechanical decoiler, straightening and blanking line

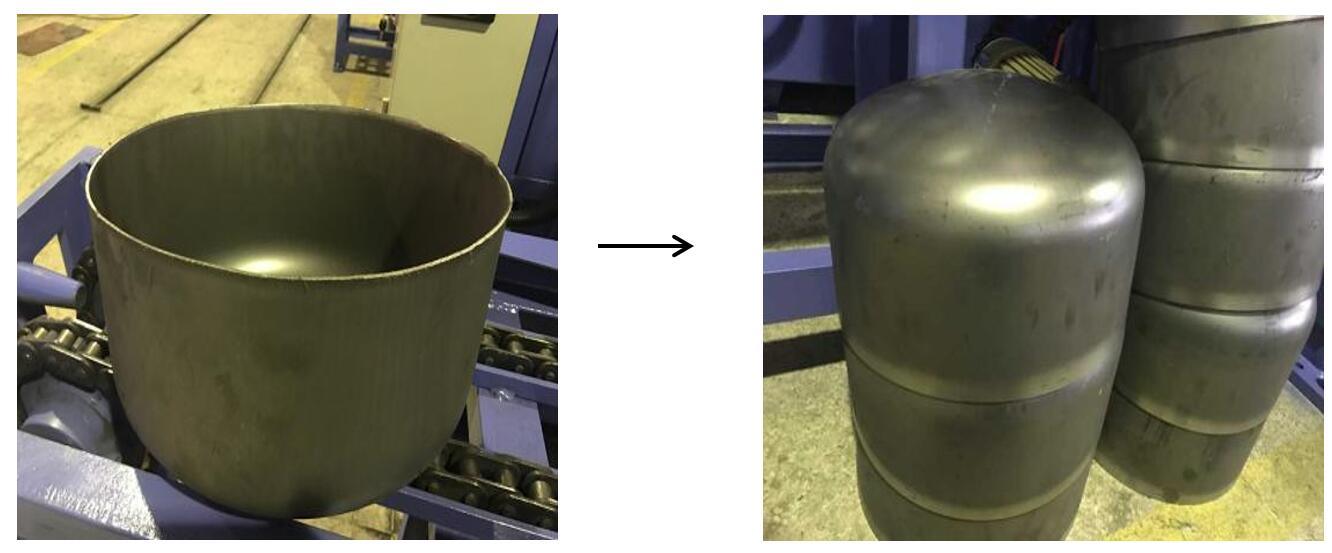

Mechanical decoiler, straightening and blanking line Deep drawing machineAutomatic flushing machine for deep drawn heads

Deep drawing machineAutomatic flushing machine for deep drawn headsafter deep drawing, the heads must be flushed before entering into the automatic welding machine

Automatic trimming & polishing machine with arms for both end dishes This high efficient machine adopts air-jacket-clamping, automatic feeding and trimming cut by inclining hob. The width and slop around the edge of shell in adjustable. This wondering machine is reliable, easy to operate and in automatically feed-in and out when connected to conveyed of the production line

Automatic hole punching & logo making machine with arms for female half/top half

Automatic hole punching & logo making machine with arms for female half/top halfPunch the hole on top of the cylinder& stamp the logo

Automatic socket welding machine with arms

Automatic socket welding machine with arms To complete the welding of valve seat ring joints. Ensure uniform forming, good appearance, weld penetration and weld width meets the technological requirements, the clamping is convenient. Using submerged arc welding technology, girth welding at one time

Automatic handle welding machine with armsComplete cylinder handle grip automatic welding. To ensure concentricity, uniform forming, good appearance, weld penetration and weld width meet the technological requirements, the clamping is convenient. CO2 gas shield welding process, complete in one time welding.

Automatic joggling machine with arms for male half/bottom halfcomplete with in and out conveyor, and with mechanical arms

Automatic bottom base welding machine with armsComplete cylinder base girth automatic welding. To ensure concentricity, uniform forming, good appearance, weld penetration and weld width meet the technological requirements, the clamping is convenient. CO2 gas shield welding process, complete in one time welding.

Longitudinal seam welding machinenot for 12.5 or even smaller cylinders only for the bigger size cylinders

Assembly &spot welding machineTo assemble both halves of the cylinder together and get ready for welding

Double head Circumferential welding machinefully automatic welding and monitoring.

Hydraulic Precision Sheet Shearing MachineFour-roller rolling machineincl. the loading and unloading

LPG gas furnaceThis furnace is designed to anneal LPG cylinders by applying flame from gas burner on the cylinders. It composes, burner, flaming chamber, smoke collector, rails, chain roller, exhaling system.

It feature includes, adjustable time, self-control thermometer, perfect heat treatment result and fire off pollution.

Automatic hydro testing machine

For 35kg. One cylinder one pressure gage, can control separately.1, Air pressure:0.6Mpa 2.Testing pressure:3.2Mpa 3,Motor pressure:3KW, 8 stations are necessary

Drying oventhe cylinder must be dried before blasting

Shot blasting machineRemove the rust, oxide layer and burr free of pipe. Clean welding slag, showing a metallic luster,

make surface achieve a bright and clean surface and to improve the adhesion force of painting to surface and improve the anti-fatigue force and anti-rust capacity of surface, improve the inherent quality of surface and prolong the lifetime of steel tube

Zinc metalizing machinePowder coating line

Coating the cylinder surface to protect the cylinder from rusting

Valve mounting machineAutomatic Air leakage testing machine

fully automatic leakage testing

Printing machine Print the paint and Logo or information

Conveyor including motor and bends

Steel Coil Decoiler and straightening315 Ton hydraulic presser for pressing the stamp on handle

Top quality 200T Mechanical punching machinePunching the hole from the steel

Handle end bending machinebend the handle end (optional)

Handle rolling machineRoll the steel become the handle shape

160T Hydraulic PresserHydraulic coding machineSteel Coil Decoiler and straightening - share with handle decolier & straightening

Vertical base Rolling machineDouble welding position welding fixture can do two welding an the same time

Base forming machine/100T mechanical punching machine Forming the base

If you interested and need more picture and more information, you are more than welcome to contact us. AND we can customize the equipment to follow your requirements.

FAQ:

LPG cylinder manufacturing equipmentQ: What size of LPG cylinder your machine can produce?

A: 6kg, 12kg,15kgs and 50kgs LPG cylinder for cooking and other size according customers' requirement.

Q: Can you design machines according LPG cylinder technical drawing?

A: Sure, please send your technical drawing to us.

Q: What are the benefits to choose your machines?

A: Our machines are strong and reliable for long term industrial manufacturing

To enable me give you correct proposal for correct machines, please tell me following details:

We need to know following information to quote you correct machineries:1.Technical Drawing of the cylinders you want to make?

2.What size of cylinder you want to produce?(6kg, 12kg)

3.What diameter and thickness of the cylinder you want to make?

4.Are you new in this area or you already have some machines in the workshop?

5.Capacity you require, i.e. how many pieces and sizes you want to make per day?

Customer Reference List1 .TK Group in Bangladesh

2. Hangzhou Yuhang Zhangshan Steel Cylinder Co.,Ltd.http://www.gangping.com, it is 3rd biggest LPG gas cylinder manufacturer in China, daily output is 18000pcs including all sizes from 2kgs to 50kgs.

3. TPA is manufacturing extremely high quality LPG cylinders for North America, European,UK and Australia. http://www.tpagas.com, we supplied automatic welding line for their China plant in Dongguan. Now we are building new LPG gas cylinder factory in Vietnam, Hangphone, at the end of August , 2017, it will be set up and commissed.

4: Shandong Huanri Group co.,Ltd., http://en.huanrigroup.cn/products_list/pmcId=24.html, they are biggest and strongest cylinder manufacturer in China, they bought our machines both for 12.5 and15kgs manufacturing and 50kgs manufacturing.

5.AYGAZ in Turkey, www.aygaz.com.tr, last week, they have already ordered the complete welding line at us after comparing with SAW welding.

6. Manchester Tank from USA

7. Sahuwala Cylinder in India

8. Delta LPG Limited (SEACOM Group), they are setting up a new plant and we will take responsible for their 12.5kgs and 33kgs production line.

Longterm Machinery Technologies are leading supplier of complete turnkey solutions for the LPG cylinder production facilities to manufacture all sizes/types of LPG gas cylinders. The whole process from blanking and body forming line, full automatic welding line, heat treatment, full automatic hydrostatic testing line, powder coating and finishing line.

Especially we have the best and automatic welding line from automatic trimming, joggling, valve bung welding, handle and bottom welding to automatic MIG body welding, the whole line involves only 7 workers, but output is 2000PCS per 8hrs.

We have been focused on cylinder welding technology since 30 years ago. During last 30 years, we keep improving our technologies on welding(TIG, MAG, MIG, SAW)and make a lot of improvement from SAW welding to MIG welding on LPG gas cylinder. Our equipment are widely used Aerospace, Petrochemical, Pressure Vessels, etc...We generated big profit by saving cost and improving welding quality on welding for our customers from all over the world, America, Russia, Turkey, Vietnam, India, Thailand, Bangladesh, South Africa, etc...

I. Production Line of LPG Gas Cylinder

Including circumferential seam welding machine

Longtitudinal seam welding machine

Hydraulic leakage test

Automatic trimming machine

Valve seat welding machine

Foot ring welding machine

Protection enclosure welding machine

End dish shaping machine

Annealing furnace

Shot blasting machine

Sandblast machine

2. Production line for Solar Water Tank

Including pressurized and non-pressurized solar water tank manufacturing line

The main equipment are as follows:

Circumferential seam welding machine

Longitudinal seam welding machine

Pipe fitting welding machine

Hole punching machine

Grooving machine

3. Production line for Steel Drum Manufacturing Line

Sheet rolling machine

Spot welding machine

Longitudinal seam welding machine

Grooving machine

Leakage testing machine

Flanging machine

Sealing machine

4. CNG Tank & Fire Extinguishier Spinning machine