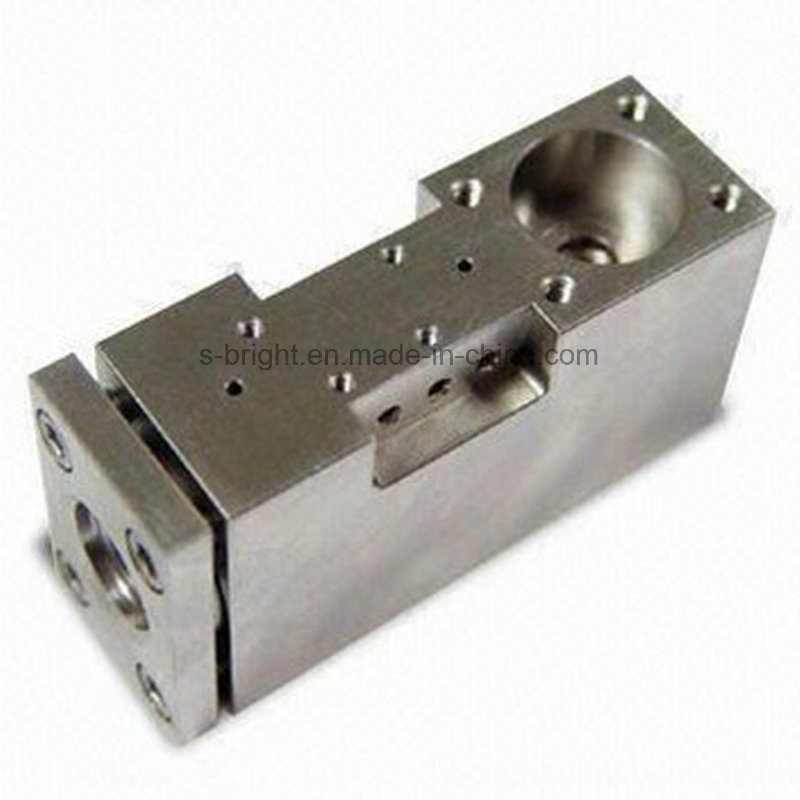

CNC Machining for Mould Parts

| Price: |

US $ 3-10/Piece |

| Min Order: |

10/Piece |

| Pay Type: |

L/C,T/T,Western Union,Paypal,Money Gram |

| Prod Model: |

w-058 |

| Surface Finishing: |

Anodize/Blacken/Polishing/Oxidation |

| Approximate Size: |

20*100*300 |

| Processing: |

CNC Machining Center, Turning,Grinding,EDM |

| Minimun Order Quantity: |

1 PCS |

| Property: |

Wear Resistance,Rust Resistance,Durable |

| Shaping Mode: |

Plastic Molding Die |

| Process Combination Type: |

Compound Die |

| Application: |

Hardware |

| Installation: |

Fixed |

Product Description

1. Dong guan S-Bright Hardware Manufacturing is specializing in all kinds of Die & mould components and machinery components for 10 years.

2. we can control the machining accuracy within 0.005mm to 0.02mm by CNC machining center, CNC Turning , Grinding ,Wire cut , EDM, etc.

3. We choose various of high quality material : aluminum, HSS, stainless steel, alloy steel, brass, bronze, tungsten carbide, POM, PC, PP , etc.

4.You can customize all kinds of parts , please send us your drawing or standard code now , we will provide you superior quality products with reasonable price.

5. Our business scope is Precision machining parts, Turning parts, mold insert, machinery parts, ceramics components, hardware fittings, carbide parts, aluminum alloy parts, Automotive parts, etc.

6. OEM&ODM are welcomed.

These products can show the capability of our main business activities, Actually, we can produce according to the drawing or sample you provide Work Type | Grinding/CNCMilling , Turning,wire cut,EDM | Material | Tool Steel/HSS/ Stainless steel/alloy/aluminum/copper |

Maximum Size | 120mm*200mm*500mm | Hardness(HRC) | 60-62 |

Tolerance | 0.005mm-0.1mm | Surface Treatment | Heat Treatment |

Sample Lead Time | 3-7 working days | Surface roughness | Ra0.1 |

Production Lead Time | Negotiable | Minimum order quantity | 1pcs |

Dongguan S-Bright Hardwares Manufacturing, , established in 2006, located in Dongguan city of Guangdong, China. We specializes in manufacturing all kinds of precision plastic injection and press die mold components (ejector pin, ejector sleeves, blade pin, core pins, support pillar, guide pin, guide bushing, interlocks, straight block set, wear plate, oilless components, self-lubricating bushings, date stamp, sprue bushing, locating ring, cavity part, hold plates, mold insert, punch, blanks, die, tools, mold spring, etc. ); And CNC machining parts (turning parts, milling parts, grinding parts, wire EDM parts, metal fabrication, forming tools).

These spare parts are widely used in optoelectronic, digital electronics, medical packaging instrument, pen, cosmetic packages, appliance, automobile and other manufacturing fields. We are familiar with DME, HASCO, STRACK, PCS, CUMSA, PUNCN, MISUMI, PROGRESSIVE, RABOURDIN, standard, etc.

We used main materials: Tool steel (such as 1.2344/H13/SKD61; 1.2379/D2/SKD11; 1.2210, A2, P20 etc. ); High speed steel (1.3343/M2/SKH51/S600; K390/ASP23/Vanadis 23 etc. ); Tungsten carbide, Stainless steel, Copper, brass, Alumium alloys, Bronze, Mild steel, POM. etc.

Dongguan S-Bright Hardwares Manufacturing has already obtained the approval ISO9001: 2008 International Quality Management System. At present,

Our mold components and CNC machining parts products are sold to European, America, Middle-East and Australia etc. Above 40 countries in the whole world.

We can process strictly all the mold components and CNC machining parts according to customer's CAD and 3D drawings. Customers can get competitive price, good quality, fast delivery time, perfect after-sales service from our company. Welcome to contact us for business cooperations.