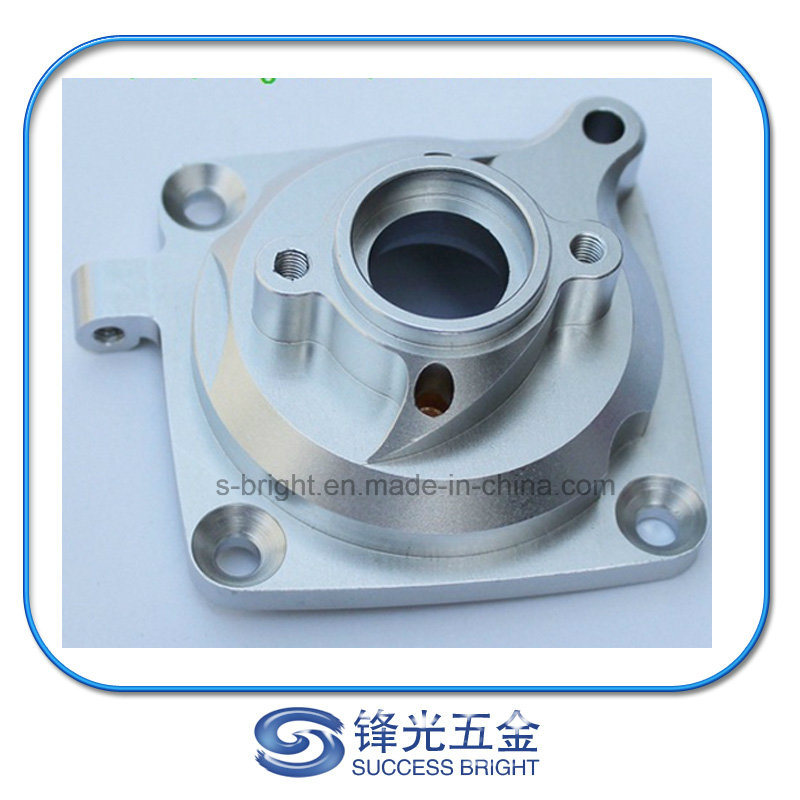

Precision Casting Hardware Machinery CNC Machining Part W-006

| Price: |

US $ 0.5/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1000/Piece |

| Pay Type: |

L/C,T/T,D/P,Paypal,Money Gram |

| Prod Model: |

W-006 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Approximate Size: |

20mm*60mm |

Product Description

Product Description

Product Description

Detailed Product Description: CNC machining parts+Hard anodized.

Material: Aluminium 6061T6, 7075-T6, 2017, 2024, 5052, 5083, 6082 etc.

Processing: 3/4/5-axis CNC milling, CNC Turning, dilling etc

Precision: Up to 0.005mm,

Surface treatment: Hard anodized. Hardness: 40-60HRC

1. All parts produced according to your CAD and 3D drawings or sample. Please send the blueprint or drawing artwork firstly, we will offer our quotation to you within 2 days.

2. Materials as below.

Aluminum, Stainless steel, 17-4pH, DERLIN, Ceramics, Carbamide alloy, PEEK etc

3. The surface finished include:

Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, golden plating etc.

4. OEM&ODM are welcomed.

5. Packing: Wooden cases, carton or on requirement.

6. Maine equipment:

Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc.

7. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, .

8. Part size: Diameter from 0.5mm to 150mm

9. Tolerance: +/-0.01mm

10, Lead time: 5-25days after the confirmation of sample

11: Minimum Order: Comply with customer's demand

12, Delivery way: EXPRESS, BY SEA OR BY AIR on your requirement.

These products are showed here only to present the capability of our business activities,

Our company specialized in manufacturing and designing of various non-standard precision parts, our service cover mechanical engineering, electronic engineering, semiconductor, tele-communication, medical equipment, automation equipments etc. We invested advanced manufacturing equipments(such as high-speed CNC Machining Center, Grinding machines, Milling machines, NC lathe, Stamping machine, Wire-Cutting machines)and quality testing machines(such as coordinate measurement machine, Micro-projector and Height Gauge etc. ) we can also provide one-stop shopping OEM.

All parts can be machined with tiny tolerance, precise dimensions and a smooth surface. Roughness typically considered to be the high frequency, short wavelength component of a measured surface.

It's our pleasure to serve you if we get your inquiry with detailed specification and drawings, we will submit our competitive offer ASAP and provide you premium quality porduct.

| (1) Materials: Aluminum, Plastics, stainless steel, nickel alloy, hast alloy, etc. |

| (2) Surface treatments: Plating, powder coating, phosphate and anodizing |

| (3) Processing method: |

| Castings, forgings, extrusions, CNC milling and turning, grinding, honing, lapping, broaching and others. |

| (4) Heat treatment capability: |

| Annealing, normalizing, tempering, nitriding, carbonitriding, carburizing and induction hardening |

| (5) Processing machine: |

| 4-axis machining center, CNC turning lathe, milling/grinding machine, centerless grinder, drilling/boring/honing |

| Machine, planer, line cutting, ultrasonic cleaning machine and other advanced production equipmen |

| (6) Inspection machine: CMM, projector, universal testing machine, surfagauge and screw gauge |

| (7) Machining precision: |

| Producing complex machined components with close tolerances in difficult to machine materials, such as straightness, perpendicularity, circular run out, concentricity, length, parallelism and symmetry |

| (8) Packing and delivery time: Standard export package, carton, wood pallet or as requirement |

| (9) After-sales service: |

| We guarantee the quality of all of our products. We have teams in Taiwan and Hong Kong ready to provide after-sales services. With 22 years of experience, we know that keeping our buyers happy is the key to our long-term success. That' s why we always offer professional service, superior quality, fast deliveries and responsible after-sales service. |

| (10) Customized designs and specifications are accepted |

| (11) OEM services are provided |

| (12) Compliant with SGS, ISO9001 certificate |

| (13) Payment Terms: T/T or L/C |

| (14) Delivery Details: FOB Zhongshan |

| (15) Country of Origin: China ( mainland ) |

| (16) Main Export Markets: Eastern Europe, North America, MID East, Central/South America, Asia etc |

Dongguan S-Bright Hardwares Manufacturing, , established in 2006, located in Dongguan city of Guangdong, China. We specializes in manufacturing all kinds of precision plastic injection and press die mold components (ejector pin, ejector sleeves, blade pin, core pins, support pillar, guide pin, guide bushing, interlocks, straight block set, wear plate, oilless components, self-lubricating bushings, date stamp, sprue bushing, locating ring, cavity part, hold plates, mold insert, punch, blanks, die, tools, mold spring, etc. ); And CNC machining parts (turning parts, milling parts, grinding parts, wire EDM parts, metal fabrication, forming tools).

These spare parts are widely used in optoelectronic, digital electronics, medical packaging instrument, pen, cosmetic packages, appliance, automobile and other manufacturing fields. We are familiar with DME, HASCO, STRACK, PCS, CUMSA, PUNCN, MISUMI, PROGRESSIVE, RABOURDIN, standard, etc.

We used main materials: Tool steel (such as 1.2344/H13/SKD61; 1.2379/D2/SKD11; 1.2210, A2, P20 etc. ); High speed steel (1.3343/M2/SKH51/S600; K390/ASP23/Vanadis 23 etc. ); Tungsten carbide, Stainless steel, Copper, brass, Alumium alloys, Bronze, Mild steel, POM. etc.

Dongguan S-Bright Hardwares Manufacturing has already obtained the approval ISO9001: 2008 International Quality Management System. At present,

Our mold components and CNC machining parts products are sold to European, America, Middle-East and Australia etc. Above 40 countries in the whole world.

We can process strictly all the mold components and CNC machining parts according to customer's CAD and 3D drawings. Customers can get competitive price, good quality, fast delivery time, perfect after-sales service from our company. Welcome to contact us for business cooperations.