| Open Size: |

0.5-400mm |

| Steel Gradet: |

45#, 55#,Spring Steel and 65mn Steel. |

| Edge Type: |

Flat Edge or Hooked Edge |

| Surface Treatmen: |

Anti Rust Oil, Anti Rust Paint |

| Apertue Tolerance: |

±3% |

| Tensile Strength: |

More Than 1000-1800MPa |

| Width: |

0.5m to 6m |

| Length: |

0.5m to 30m |

| Application: |

Cages |

| Hole Shape: |

Square |

| Weave Technique: |

Plain Weave |

| Weave Method: |

Flat-Topped Curved |

| Packing: |

Pallet |

| Certification: |

ISO9001 |

| Material: |

High Carbon Steel and Spring Steel |

| Feature: |

Anti Wear and Anti Earthquake |

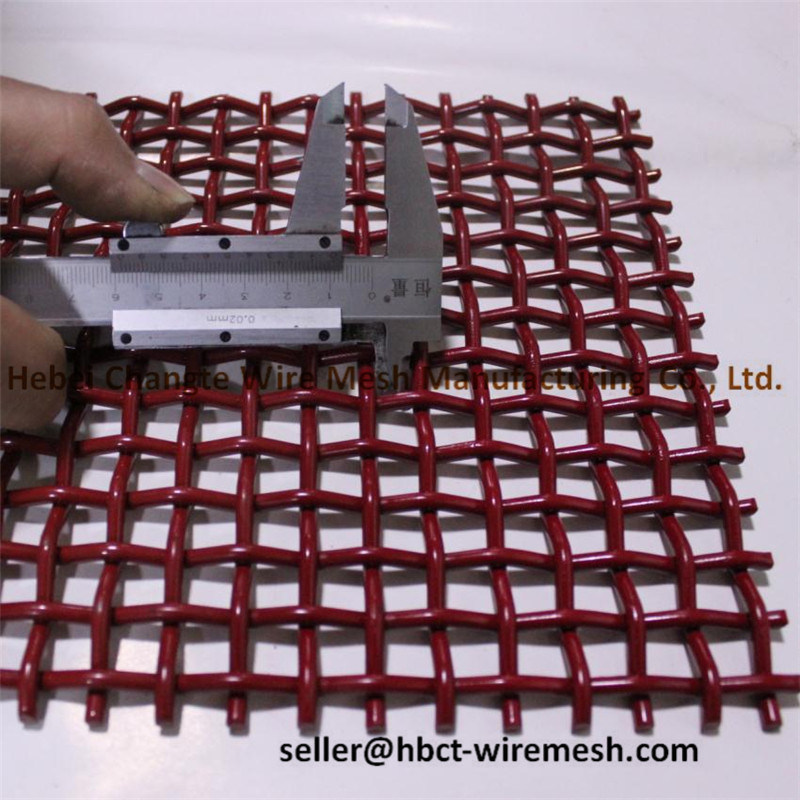

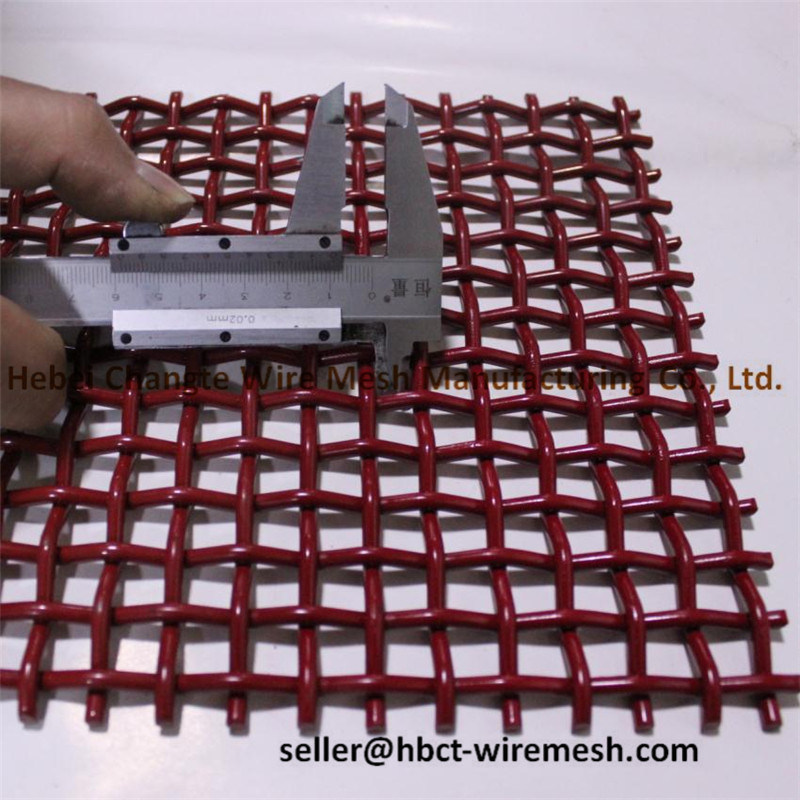

| Wire Diameter: |

0.2mm to 15mm |

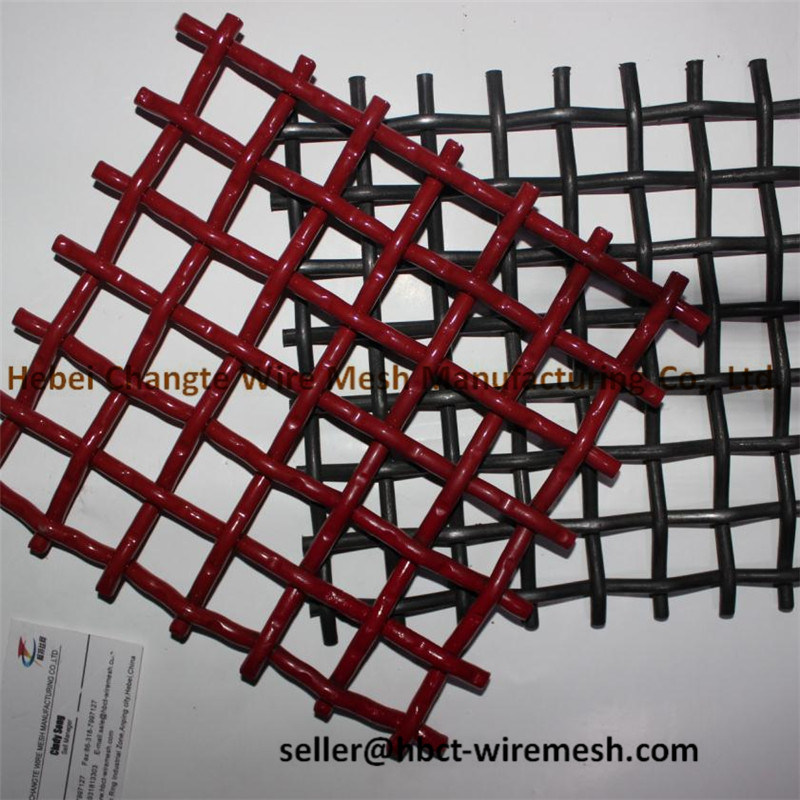

| Color: |

Black, Red, White, etc. |

Product Description

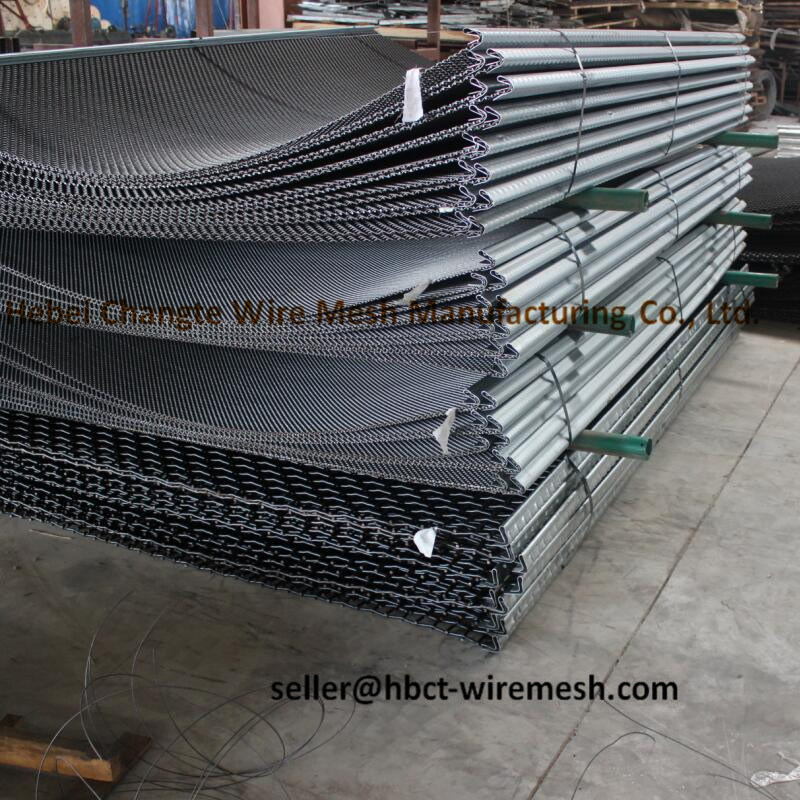

Factory Produces 65mn 45mn Woven Vibrating Crimped Wire Mesh Heavier woven wires must be pre-crimped. The material remains stable and rigid after the crimping process. Our pre-crimped woven wire mesh is available in intercrimp, lock crimp, plain weave and flat top woven styles, and it is ideal for architectural applications.

1. Angle: 30 degrees, 45 degrees

2. crimped wire mesh Shape: v-shaped, u-shaped

3. hook crimped woven wire mesh Hook type: positive check, positive check

4 . woven wire mesh Material: Stainless steel wire,45Mn steel,65Mn steel,high carbon steel, carbon steel, nickel steel and nonferrous wire.

5 . hook crimped woven wire mesh Weaving type: Plain, intermediate, crimped

6 .Process: Made with pre-crimped wire in the method of locked crimp, double plain weave, single wave weave, double plain weave, double crimp, space weave.

7 . hook woven wire mesh Application: Screening in mine, petroleum, chemical, building and food industry. Used in machinery parts, packing, barbecue, hardware products, handicrafts, wire baskets, food machinery, road and railway, etc. Also used in screening and grading of solid materials and filtering of liquid and quarry, etc.

WOVEN WIRE CRIMPS

Conventional Double Crimp Woven Wire

Most common type of woven wire. It is used where the opening is relatively small in comparison to the wire diameter.

Lock Crimp Woven Wire

This woven wire type is used only in coarse specifications to maintain the accuracy of weave throughout screen life, where the opening is large with respect to wire diameter.

Inter Crimp Woven Wire

Used in coarse weaves of lighter gauge woven wire to provide greater stability, tightness of weave and maximum rigidity. Very common in wire mesh openings larger than 1/2" (12.7mm).

Flat Top Woven Wire

Usually starts at 5/8" (15.875 mm) opening and larger. Provides long abrasive resistant life, since there are no projections on top to wear. Flat top woven wire offers the least resistance to flow and is very popular in certain architectural and structural applications where a smooth surface on one side is desirable.

Features ,

- Optimum bending strength

- High abrasion resistance

- Accurate dimensions

- Excellent stability

Applications ,- Mining industry

- Coal factory

- Construction industry

- Food processing and meat industry

Used for ,

- Grid window

- Poultry protection

- Concrete reinforcement

- Building construction

| Aperture mm | Aperture Tolerance mm | Wire mm | Edge Length mm | Weight kg/m2 |

| | Minimum | Maximum | | Minimum | Maximum | |

| 101.60 | 98.55 | 104.65 | 12.70 | 12.70 | 50.80 | 17.92 |

| 88.90 | 86.23 | 91.57 | 12.70 | 12.70 | 44.45 | 20.16 |

| 76.20 | 73.91 | 78.49 | 12.70 | 12.70 | 38.10 | 23.04 |

| 63.50 | 61.60 | 65.41 | 12.70 | 12.70 | 31.75 | 26.88 |

| 63.50 | 61.60 | 65.41 | 9.19 | 9.19 | 31.75 | 14.76 |

| 57.15 | 55.44 | 58.86 | 9.19 | 9.19 | 28.58 | 16.17 |

| 50.80 | 49.28 | 52.32 | 12.70 | 12.70 | 25.40 | 32.26 |

| 50.80 | 49.28 | 52.32 | 11.10 | 11.10 | 25.40 | 25.28 |

| 50.80 | 49.28 | 52.32 | 9.19 | 11.10 | 25.40 | 17.88 |

| 50.80 | 49.28 | 52.32 | 7.92 | 7.92 | 25.40 | 13.57 |

| 44.45 | 43.12 | 45.78 | 9.19 | 9.19 | 22.23 | 20.00 |

| 44.45 | 43.12 | 45.78 | 7.92 | 7.92 | 22.23 | 15.21 |

| 41.28 | 40.04 | 42.51 | 9.19 | 9.19 | 20.64 | 21.25 |

| 41.28 | 40.04 | 42.51 | 7.92 | 7.92 | 20.64 | 16.19 |

| 38.10 | 36.69 | 39.24 | 9.19 | 9.19 | 19.05 | 22.68 |

| 38.10 | 36.69 | 39.24 | 7.92 | 7.92 | 19.05 | 17.31 |

| 38.10 | 36.69 | 39.24 | 7.19 | 7.19 | 19.05 | 14.49 |

| 31.75 | 30.80 | 32.70 | 9.19 | 9.19 | 15.88 | 26.20 |

| 31.75 | 30.80 | 32.70 | 7.92 | 7.92 | 15.88 | 20.08 |

| 31.75 | 30.80 | 32.70 | 7.19 | 7.19 | 15.88 | 16.85 |

| 28.58 | 27.72 | 29.43 | 7.92 | 7.92 | 14.29 | 21.83 |

| 28.58 | 27.72 | 29.43 | 7.19 | 7.19 | 14.29 | 18.35 |

| 25.40 | 24.64 | 26.16 | 7.92 | 7.92 | 12.70 | 23.91 |

| 25.40 | 24.64 | 26.16 | 7.19 | 7.19 | 12.70 | 20.14 |

| 19.05 | 18.48 | 19.62 | 5.72 | 5.72 | 9.53 | 16.78 |

| 15.88 | 15.40 | 16.35 | 4.50 | 4.50 | 7.94 | 12.62 |

| 11.00 | 10.67 | 11.33 | 4.00 | 4.00 | 5.50 | 13.55 |

| 10.00 | 9.70 | 10.03 | 4.00 | 4.00 | 5.00 | 14.51 |

| 8.00 | 7.76 | 8.24 | 4.00 | 4.00 | 4.00 | 16.93 |

| 6.35 | 6.16 | 6.54 | 2.67 | 2.67 | 3.18 | 10.04 |

| 6.30 | 6.11 | 6.49 | 2.50 | 2.50 | 3.15 | 9.93 |

| 4.00 | 3.88 | 4.12 | 2.00 | 2.00 | 2.00 | 9.31 |

| 3.00 | 2.91 | 3.09 | 2.00 | 2.00 | 2.00 | 11.17 |

| 2.00 | 1.94 | 2.06 | 1.50 | 1.50 | 1.50 | 8.99 |

If you want to get price, please tell me below specification size.

1.Material

2.Wire diameter

3.Mesh

4.Width and length

5.Which edge with hook and hook size

6.Quantity

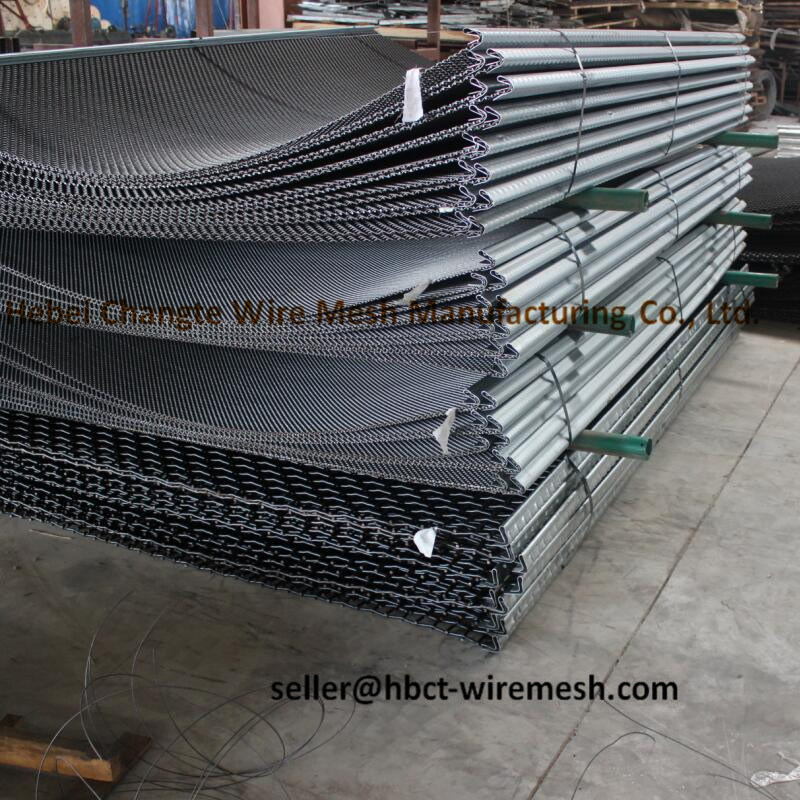

Hebei Changte Wire Mesh Manufacturing Co., Ltd is located in Anping, the famous Wire Mesh Land of China. Established in 2000, today Changte has developed to be a major company who equipped with more than 200 sets wire mesh production machines, and engaged in various of wire mesh products'sale and production.

Our factory has advanced equipments, skilled workers, complete quality management system, strong R&D capability. With choice materials, we are mainly manufacture Crimped wire mesh, Woven wire mesh, Filter screen mesh, Self cleaning screen mesh, Square wire mesh, Gabion wire mesh, Wire mesh fence, Razor barbed wire etc.

As our company is growing day by day, the list of clients is also increasing and today; We have marked a niche in not only domestic but also in international market. With our internationally certified products, we have revolutionized the global market place.

Our clients are spread across the corners of world, recommending our products for their durability, designing accuracy, dimensional tolerance and adaptability to work under adverse conditions.

For export, utmost attention is paid towards packaging of the products in order to protect them from damage, scratches and dents during the transit.

Today, we are exporting our products to some of the major international markets that are as follows:

UAE

Bahrain

Kuwait

USA

Australia

New Zealand

Jordan

Dubai

South

Zambia

Ivory Coast

Japan

Russia

South Africa

Germany

We adopt to the win-win cooperation model and Set up customer-oriented concept.

If there is anything we can do for you, please send your inquiry. We will try our best to help you. Welcome to visit our factory.