| Prod Model: |

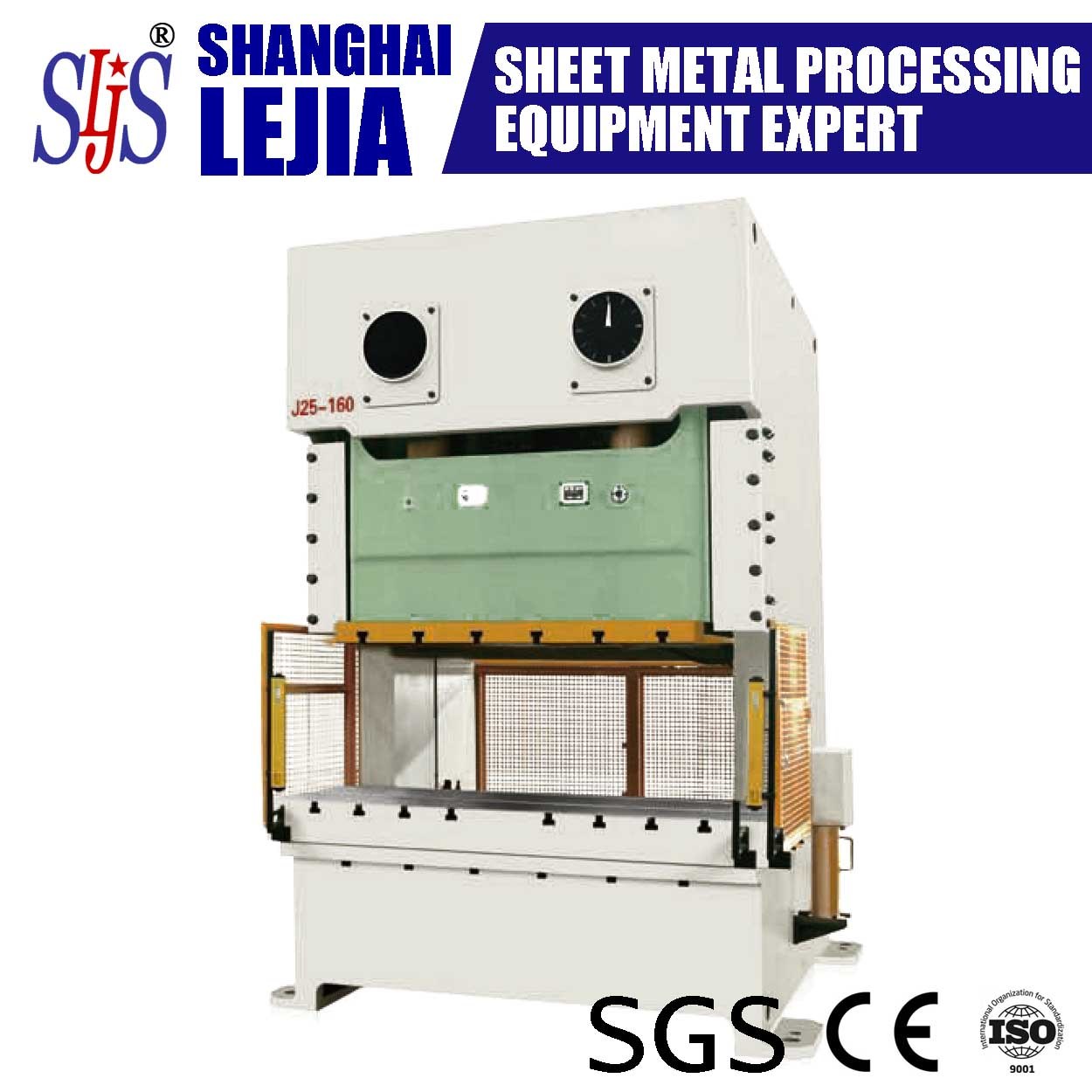

J25 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Machine Type: |

Mechanical Press |

| Shape: |

C-Frame |

| Clutch-Brake: |

Pneumatic Combination Friction Cluth-Brake |

| Slide: |

Six-Side Long Rectangle Guides |

| Imported Hydraulic Overload Protection: |

Motorized Die Height Adjustment |

| Type: |

General Punching Machine |

| Automatic Grade: |

Automatic |

| Power Source: |

Mechanical Drive |

| Precision: |

High Precision |

| Controlling Mode: |

PLC |

Product Description

1) Usage

J25 Series C-Frame Double Crank Press can be applied for punching and shallow drawing of largesized plates. It may also be equipped with multi-stage dies or other transfer dies for processing parts and components of complex structures.

2) Main Structure Features

A. A whole steel welded frame, high rigidity and less deformation, ensuring the capacity for bearing heavy load.

B. Cast structure and six-side long rectangle guides, ensuring high moving precision and high accuracy, extending the service life of die.

C. Pneumatic combination friction clutch-brake, with low noise and long service life, ensure flexible action and reliable safety.

D. Imported hydraulic overload protection device, offering convenient maintenance and high sensitivity in effectively. Effect emergent stop against overload, protecting the dies and preventing damages to the press.

E. The machine adopts automatic grease lubrication system with timing and rations lubricated.

F. The adjustment for die-setting height is motorized and a digital indicator for die-setting height is equipped.

G. Arranged the crankshaft longtitudinally, and submerge the driving.

H. The machine adopts pneumatic balance cylinders to balance the weight of slide and upper die, to ensure thte press moving stably.

I. MITSUBISHI PLC electrical control system allows various auto-equipment reprogrammed according to different requirements and perform various functions, to ensure high reliability and adaptability.

| Model | J25-80 | J25-110 | J25-160 | J25-200 | J25-250 | J25-315 |

| Description | Unit | L | S | L | S | L | S | L | S | L | S | L | S |

| Nominal Pressure | kN | 800 | 1100 | 1600 | 2000 | 2500 | 3150 |

| Nominal Pressure Stroke | mm | 4.5 | 2.5 | 5 | 3 | 6 | 3 | 7 | 4 | 7 | 4 | 8 | 5 |

| Slide Stroke | mm | 160 | 90 | 180 | 110 | 200 | 130 | 230 | 150 | 250 | 180 | 250 | 180 |

| Stroke | S.P.M | 40-75 | 50-90 | 35-65 | 45-80 | 30-50 | 35-65 | 25-45 | 30-55 | 20-40 | 30-50 | 20-35 | 25-45 |

| Max.Die Set Height | mm | 380 | 415 | 400 | 435 | 450 | 485 | 500 | 540 | 550 | 585 | 550 | 585 |

| Die Height Adjustment | mm | 80 | 90 | 100 | 110 | 120 | 120 |

| Throat Depth | mm | 310 | 350 | 390 | 430 | 470 | 470 |

| Distance between Uprights | mm | 1350 | 1470 | 1610 | 1960 | 2100 | 2170 |

| Bottom Size of Slide | L-R | mm | 1200 | 1360 | 1500 | 1850 | 2000 | 2100 |

| F-B | mm | 460 | 520 | 580 | 650 | 700 | 700 |

| Size of Worktable | L-R | mm | 1650 | 1880 | 2040 | 2420 | 2600 | 2700 |

| F-B | mm | 600 | 680 | 760 | 840 | 920 | 920 |

| Overall Dimension | L-R | mm | 1850 | 2000 | 2200 | 2670 | 2900 | 3050 |

| F-B | mm | 1800 | 1860 | 2100 | 2310 | 2650 | 2960 |

| Height | mm | 3000 | 3150 | 3450 | 4200 | 4750 | 4900 |

| Main Motor Power | kW | 11 | 15 | 22 | 22 | 30 | 37 |

| Total Weight | kg | 12500 | 16000 | 22000 | 31000 | 40000 | 46000 |

Shanghai Lejia CNC Machine Co., Ltd. is a national new technological enterprise and national important "Torch Plan" implementation organization with integration of research and development, machinery manufacturing, tools designing and building, sales and import and export authority rigths. We are professional manufacturing company holding many domestic and international certificates.

Manufacture ranges: CNC Press brake Machine, shearing machine, CNC-Punch, and Slotting Machine, Rolling bending machine, Straightening, Unrolling, Shearing Production Line and normal Forging Machinery. And pressbrake tools. Shearing blade. Punch tools, etc. The products are awarded highly by the clients with the fame of those precise, reliable and high qualified products produced by the state -in- art manufacturing techniques, which are of reasonable price and excellent after-sale-service.

Our Company is dedicated to contribution for nation by sustainable promotion and improvement in the field of CNC machinery, CNC Machinery Tools and-Cutter-localization.