| Prod Model: |

JIS/DIN/OEM/HASCO/MISUMI |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Products Standard: |

Hasco, Dme, JIS, DIN |

| Material: |

SKD61, Skh51, SKD11, 1.2344, 1.2343 |

| Certificate: |

SGS, ISO9001:2008 |

| Stadnard: |

Dme/JIS/Hasco Standard and Customized |

| Shipping Term: |

DHL/UPS/FedEx or by Vessal |

| Payment Term: |

30% Deposit and 70% Before Goods Shipped out |

| Shaping Mode: |

Injection Mould |

| Process Combination Type: |

Progressive Die |

| Application: |

Hardware |

| Installation: |

Semi Fixed |

| Design Software: |

Pdf, CAD, PRO-E, Ug, Other Drawing Formats |

| Certification: |

ISO9001:2008 |

Product Description

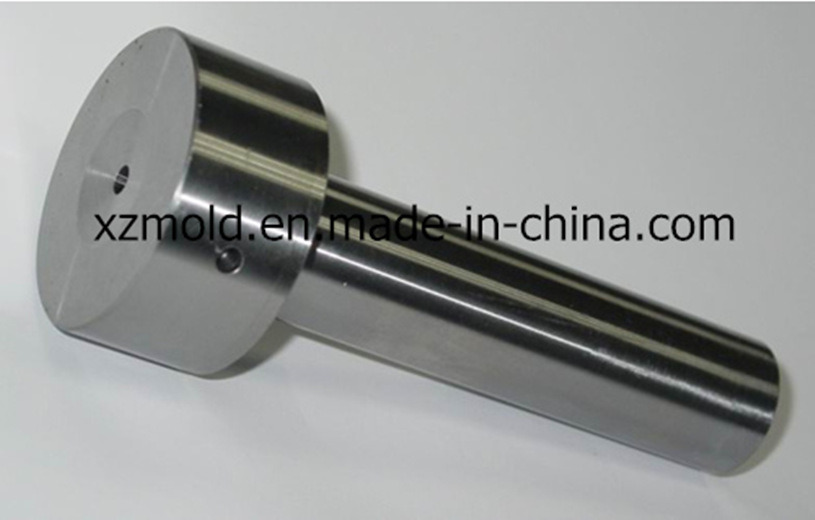

Product's name: Hardened Sprue Bushings(Ground and Polished)

Raw Matarial: SKD61/1.2344/ H13 ,SKH51/HSS,SKD11S.A.E.6145 steel hardened.Heatment: Nitrided

Hardness: Inner HRC60-62

(If it be nitrided,the inner surface hardness will be 36±2,the surface hardness will be HV900-1100)

Packing: 1)Double layers plastic bag package

2)Sponge

3)Thick cartons box

4) In wooden case

1.Factory information:

1.Factory information:| Company:Dong guan city Xiang zhen mold parts Co.,Ltd |

| Website: www.nsmmold.com |

| Location: Dong guan,China (close to Hong Kong,Shen Zhen,Guang Zhou) |

| Software: PDF,Auto-CAD,Pro-E,UG etc are available |

| Employee: 100-200 |

| Manufacture in: High precision mold parts/Hot-runner and related parts/CNC/EDM parts/Grinding parts/Customized mold parts |

| Export Markets: Global |

2. Equipment and Inspection measurement:| Description | Machine type name | Origin from and brand | Quantity | Precision level(mm) |

| Processing equipment | CNC Processing | Taiwan | 3 | ±0.01 |

| CNC Lathe | Japan | 2 | ±0.003 |

| WEDM (Low speed wire cutting) | Japan | 2 | ±0.005

±0.002 |

| WEDM (high-speed wire cutting) | China | 2 | ±0.005

±0.01 |

| Flood grinder | China | 1 | ±0.002 |

| EDM | Taiwan | 2 | ±0.005 |

| ID Grinder | Taiwan | 3 | ±0.001 |

| Depth drill | Taiwan | 3 | ±0.02 |

| Automatic grinder | Taiwan | 2 | ±0.001 |

| Centerless Grinder | Taiwan | 12 | ±0.001 |

| Surface Grinder | Japan | 2 | ±0.001 |

| Surface Grinder | Taiwan | 5 | ±0.001 |

| Vertical hydraulic Heading Machine | China | 2 | |

| Semi-automatic Heading Machine | Taiwan | 3 | |

| Manual Heading Machine | Taiwan | 2 | |

| Automatic forging machine | Taiwan | 1 | |

| Bench grinders | Taiwan | 2 | |

| Punch Grinder | Taiwan | 6 | ±0.002 |

| Lathe | China | 4 | ±0.01 |

| 32 type Lathe | Taiwan | 4 | |

| 25 type Lathe | Taiwan | 3 | ±0.01 |

| 15 type Lathe | Taiwan | 10 | ±0.01 |

| Milling Machine | Taiwan | 6 | ±0.01 |

| Liquid nitriding furnace | China | 1 | |

| Tempering furnace | China | 2 | |

| Oxidation furnace | China | 1 | |

| Inspection equipment | Rockwell hardness | Shanghai | 1 | ±0.5° |

| Height gage | Japan | 2 | 0.001mm |

| Microscope | Shanghai | 2 | 0.0001mm |

| Three-dimensional | Germany(Zeiss) | 1 | ±0.002 |

| 2.5 dimension | Taiwan | 1 | ±0.001 |

| Digital Projector | Taiwan | 1 | ±0.002 |

| Vickers hardness tester | Taiwan | 1 | |

| Concentricity device | Taiwan | 2 | ±0.001 |

| Digital Micrometer calipers | Taiwan | Multiple | Conventional |

| slide calliper rule | Taiwan | Multiple | Conventional |

| Height Gauge | Taiwan | 1 | Conventional |

| Roughometer | Japan | 1 | Conventional |

3.Precision parts information:| Accuracy for EDM | Clearance angle | R0.03mm |

| Surface Roughness | Ra0.05mm |

| Accuracy for Grinding | Clearance angle | R0.02mm |

| Shape tolerence | ±0.001mm |

| Accuracy for surface | Ra0.05mm |

| Minimum thickness | 0.1mm |

| Minimum groove | Wide 0.01mm;Depth 0.25mm |

| Material | Japan:SKD61/SKD11/SKH51/SUJ2 |

| Germany:1.2343/1.2344 or as Customer's request. |

| Size | Standard as DME/Hasco/Punch etc or Customized |

| MOQ | 1Pcs/Type |

| Price | EXW/FOB/CNF/CIF |

| Payment | T/T or %advance-%against shippment |

4.Why choose us:*-Quality: Qualified Raw Material

Reliable Machines

Mature process

Skillful employees

Strict Quality Control

*-Price: Competitive price /Reasonable margin

*-Service: Any inquiries replied within 24 hours

Quick Delivery

Quick Response (7/7)

Warranty: Depend on product type.

Stardand parts:500K---2M cycles

5. How to order: (1) Send us drawing or standard code & size

(2) We quote you within 1 day (except Saturday and Sunday)

(3) Get agreement with price and sign PO or Contract

(4) Make payment in advance

(5)If sample required,we will make sample first

6. FQA:(1) Q:Where is your factory located? How can I vist there? A:Our factory is located in A # Building, Ju Long Industrial Park, Tian Xin Village, Huang Jiang Town,Dong Guan,

China. All our clients from home or abroad are warmly welcomed to visit us at any time.

(2) Q:Are you a factory or a trading company? A:We are factory with 2 plants, and our company have engaged in production and foreign trade sales for so many years.

(3) Q:Before shipment how to make sure the produce quality? A:You can come to our factory or let the third party for inspection, if not we will be as your inspection worker.

We can supply you the inspection reports.

(4) Q:Do you provide free sample? A:Yes,we could offer some samples for free, but freight collect.

(5) Q:How do I know about the delivery? A:We will inform you of the tracking number once we get it from shipping agent. Also we will keep updating the

latest shipping information for you.

(6) Q:What will you do after sales? A:We have after-sales servise, when you received our products,we will follow up and await your feedback.

Any question related to our ejector pins,our experienced engineers are ready to help.

7. Contact Info:Sales Manager: NancyTel: +86 769-83516188 ext 831

Fax: +86 769-83510866/83510966

Dongguan City Xiangzhen Mold Parts Co., Ltd. is a professional manufacturer of standard components and plastic molds.

The ranges of our products include standard (HASCO, DME and JIS) and customized high-precision ejector pins, ejector sleeves, shoulder ejector pins, blade ejector pins, core pins, guide posts, bushings, punching parts, fixtures and other parts.

We not only produce these standard components, but also help solve problems in the production of plastic molds and die casting parts.

Our factory is equipped with Taiwanese CNC working centers, NC gun drilling machines, centerless grinders, cylindrical grinding machines, internal grinding and honing machines, high-speed precision desk-top lathes and surface grinding machines.

We follow the spirit of "teamwork" and establish close and cooperative partnership with our customers. The company has cooperated with many clients both from domestic and overseas, and has obtained consistently high praise from our customers since it was set up. We sincerely welcome you to visit our company or contact us for cooperation!

We have significantly essential support from local customers that are leading mould manufacturers and reputable foreign agents in mould industry.