Product Description

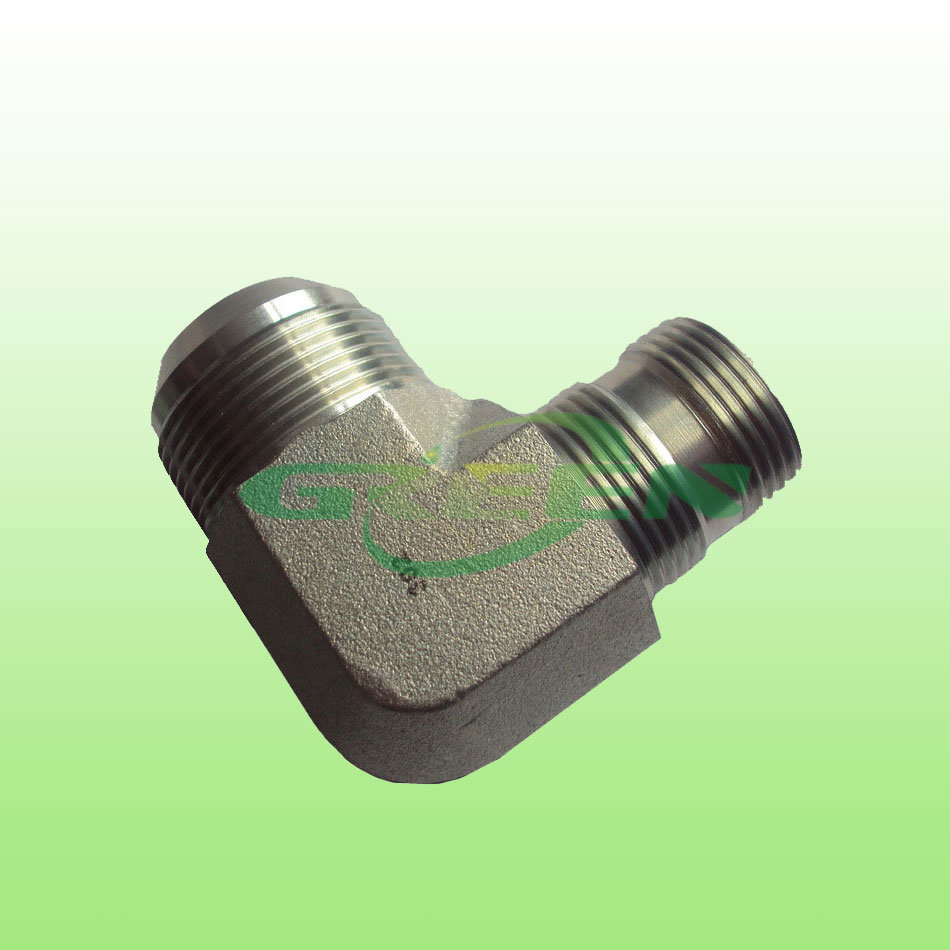

Precision Casting Fire Suppression Hydraulic Pipe Fittings Specification:1. Material: aluminum, steel, stainless steel, brass, copper, bronze

2. Thread model: UNF, JIC, NPT, BSPT as needed

3. Application: machinery, transportation, mines, oil fields, agriculture equipment, vehicle, heavy industry and more

4. OEM & ODM welcome

5. Surface finish: anodized, oxide, plating, brushing, polishing, blackened, powder coating, sandblasting, laser engraving and more

JIC NPT SAE hydraulic fittings

Straights:

1.Male O-Ring Boss to Female Pipe NPTF | 4.Male JIC 37° Flare on Run to Male JIC 37° |

2.Male O-Ring Boss to Female Pipe Swivel NPTF | 5.Male JIC 37° Flare to Female JIC 37° Flare |

3.Male JIC 37° Flare on Run to Female JIC 37° | 6.O-Rings for Straight Thread Boss Fittings |

1.Female JIC 37° Flare Swivel to Male Pipe NPTF - 90° | 4.Male Pipe NPTF to Female Pipe NPTF - Brass - 90° |

2.Male JIC 37° Flare to Male Pipe NPTF - 45° | 5.Male JIC 37° Flare to Female JIC 37° Flare Swivel - 45° |

3.Male O-Ring Boss to Male JIC 37° Flare - 90° | 6.Male SAE 45° Flare to Male Pipe NPTF - Brass - 45° |

Tees,cross,caps and plugs:

1.Female JIC 37° Flare Cap | 4.Male JIC 37° Flare on Run to Male O-Ring Boss - Tee |

2.Male JIC 37° Flare Plug | 5.Male JIC 37° Flare - Tee |

3.Male JIC 37° Flare on Run to Male Pipe NPTF - Tee | 6.Tube Sleeve Nut |

BSP METRIC JIS DIN hydraulic fittings

Straights:

1.Male British Standard Pipe Parallel to Female Pipe | 4.O-Rings for DIN Light Series |

2.Female British Standard Pipe Parallel to Female NPTF | 5.Female British Standard Pipe Parallel Swivel |

3.Male Metric O-Ring Plug | 6.Male Metric with O-Ring to Male JIC 37° Flare |

45°or 90°elbows:

1.Male Metric with O-Ring to Male JIC 37° Flare - 90° |

2.Male British Standard Pipe Parallel with O-Ring to Male Flat-Face O-Ring - 45° |

3.Male British Standard Pipe Tapered Thread toMale JIC 37° Flare - 90° |

Tees,cross,caps and plugs

1.Male Komatsu to Female Komatsu to Male Komatsu - Tee |

2.Female DIN 24° Cone - Light Series Cap |

3Male British Standard Pipe Parallel Plug |

Performance:

1. Hydraulic proof pressure test (1.5 times the maximum permissible working pressure):no leakage

2.Dismantling and reassembly test (dismantle ten times): no leakage.

3.Minimum hydrostatic pressure test (four times the maximum permissible ambient pressure rating): no leakage

4.Vacuum test (1*10-4 mbar or greater):the leak rate less than 1*10-8 mbar 1/s

5.Maximum static gas pressure test (with nitrogen gas to 150% of pressure rating):no visible bubbles.

6.Hydraulic impulse and vibration test (the pressure impulses at between 0.5Hz and 1.7Hz and vibration at between 23Hz and 47Hz): no leakage.

7.Thermal cycle test (ambient to +80°C and then to -25°C with a hydrostatic pressure):no evidence of leakage.

8.Pneumatic pressure vibration test (the frequency of vibration shall be set at 45Hz and complete 20*106cycles): without failure.

9.Fire test (in accordance with BS ISO 19921): no leakage.

10.Corrosion resistance test (the duration of exposure at least 168h): no visible evidence of corrosion)

11.Dee water submersion test (equivalent to 3048m sea water): no helium

Perameter Data : | 1.Material: | Brass ,Carbon Steel ,SS303,SS304 SS316, 316L etc. |

| 2.Size: | 1/2" NPT/BSPT/BSPP, or as your request. |

| 3.Processing | Precision casting ,Forged,CNC machining ,Surface treatment. |

| 4.Surface treatment: | Polishing ,Zinc plated ,Electrolytic , |

| 5.Sample Time/charge: | (1) 3-5days----For customized. (2) 1day----For existing.

as your design |

| 6.OEM ODM Accepted: | Yes |

| 7.Production Capacity: | 30,000pcs Per month. |

| 8.Payment Term: | L/C,T/T,D/P,D/A,PAYPAL,WESTERN UNION,MONEY GRAM |

| 9.Standard: | JIC/BSP/NPT/BSPT/SAE/Metric and etc. |

Samples Free:Contact us from free samples , delivery time will be in 5-7 working days and mass order delivery time wil be 7-15 working days by air ,by sea or be express (Fedex ,DHL ,UPS ,TNT,EMS etc.)

Company information and advantages:1. Full production chain, from opening moulds to CNC machining

Company information and advantages:1. Full production chain, from opening moulds to CNC machining

2. Advanced equipment: CNC center, CNC milling machine, CNC turning machine, CNC drilling machine, CNC lathes, lathe, 4 axis machine and more

3. Professional quality inspection department with completed inspection equipment: CMM, projection, calipers, micro caliper, thread micro caliper, pin gauge, caliper gauge, pass meter, pass meter and more

4. Our promise and target: 100% qualified production customer take, any unqualified products would be kept in our factory

5. We not only want to be a supplier, but be an honest partner, we are willing to assist any customer solve kinds of difficulties, supply high quality products with reasonable prices at the same our excellent servicesContact us now :Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "Quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

Founded in 2008, Green Spray Technology Co., Ltd. is a manufacturer and exporter specialized in kinds of hardware products 7years long, located in Changan town, Dongguan city which famous for hardware electronics industry city with convenient transportation access.

Green Spray is a comprehensive group integrated R&D, production and sales together, not only have a well-equipped facilities casting factory with advanced CNC machine lines, but also have strict efficient TQM system, from the material to the finished products must be 100% quality control and inspection, both OEM &ODM are available. The products have been already exported to more than thirty overseas countries.

Green Spray supplies wide ranges hardware products for various fields in different material, such as: Spray nozzles for washing, cleaning, cooling, humidifying and environmental protection, casting fittings, machining fittings, fire application fittings, kinds of CNC machine parts, casting accessories and so on.

Not only selling, Green Spray also provides professional technology support for the customers, according to customers's actual application, company's strong technology team will give professional suggestion and detailed design, Except supplying high quality products and on-time delivery, highly-efficient excellent services is provided all the time...

Honesty, stabilizing and development is life of Green Spray people, sincerely welcome worldwide clients guide and supervise the work, looking forward to establishing long-term win-win business relationship. Choosing Green Spray Company, not only you will have a credible supplier but also you will have a reliable friendly partner.