| Prod Model: |

Profile |

| Application: |

Dressing |

| Feature: |

High Precision |

| Characteristic: |

Good Profile Consistency |

| Manufacturer: |

E-Grind |

| Material: |

Diamond |

| Abrasive: |

Superabrasive |

| Working Style: |

Surface Grinding |

| Shapes: |

All Kinds of Shape Are Availablel |

| Types: |

Profile Grinding |

| Grain Size: |

D151-D1181 |

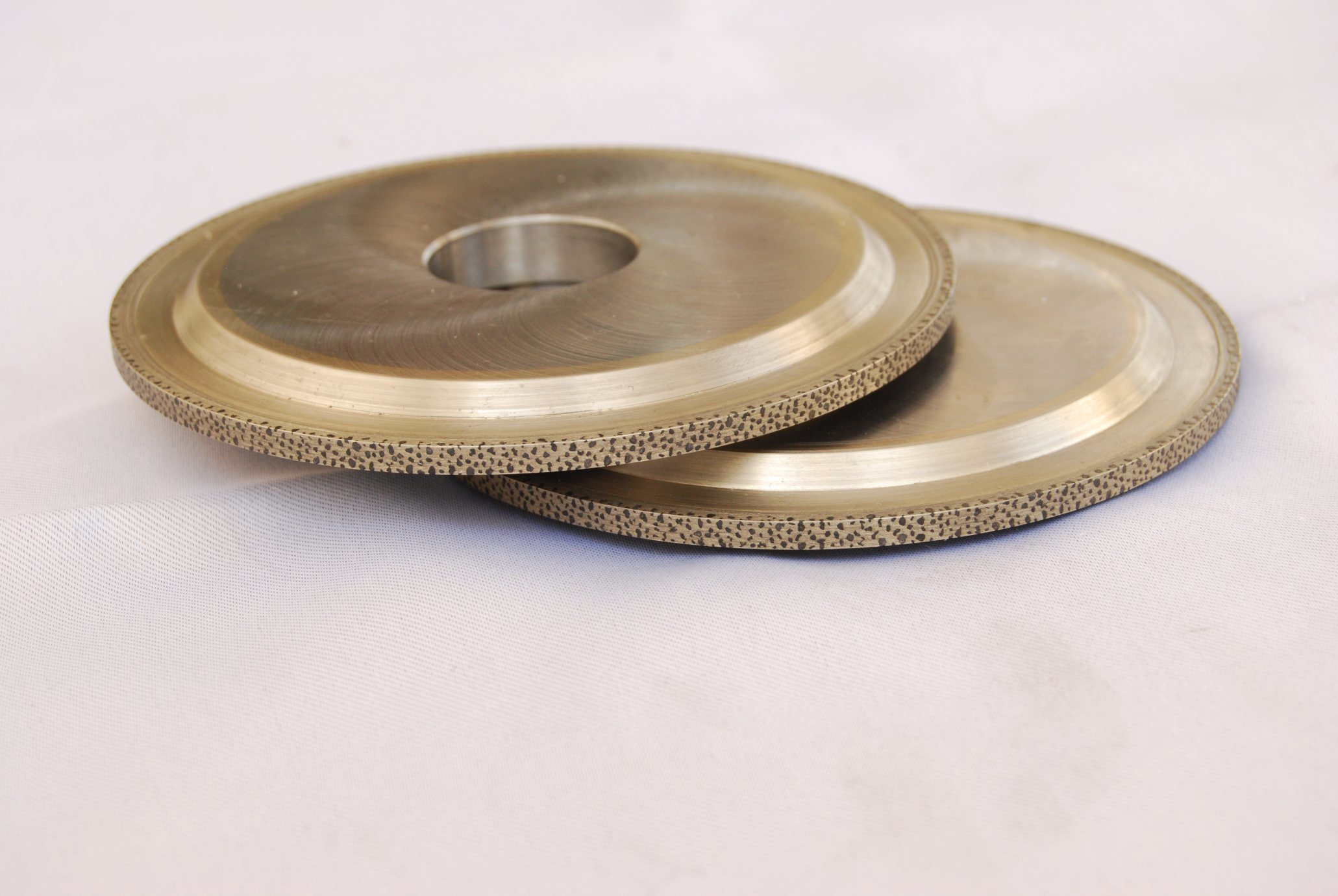

Product Description

Diamond Dressing RollerVitrified grinding wheels with Silicon Carbide, Aluminum Oxide, Diamond or CBN as grinding media loose their profile accuracy and cutting capacity after extended use. In order to restore the same, the grinding wheels have to be subjected to a dressing process.

At present, cylindrical grind wheels or wheels having simple profiles are dressed by means of diamond-single-grit dressers, diamond-multiple-stone-dressers, or by means of diamond-dressing plates, in a tolerance range of +/-0.05 mm.

For higher precision requirements like +/-0.005mm and especially for complicated profile shapes, the dressing of grinding wheels can be accomplished only by highly precise diamond rolls.

Diamond rolls are primarily used for manufacture in large series.

Details of Roller| Feature | Diamond dressing roller is a new generation dressing tool for formed grinding processing grinding wheel. Compared with common diamond dressing pen, it has excellence of high efficiency, good profile consistency and steady processing quality. What we make high precision dressing roller by E-GRIND has characteristic of high precision outline and wide availability. Not only can we make R 0.1mm small round arc but also can make less than 1mm versatile tooth complicated formed dressing roller and as well as large formed dressing roller which the high diameter ratio is more than 1.5, the height is larger than 200mm, this is the best dressing roller of high precision, high efficiency for formed grinding. |

| Application | Dressing roller is widely used for spaceflight aviation, automobile, metallurgy, textile industry, packing machine and tool profession. It involves tenon of motor vane on aviation, screw of car direction machine, universal joint, car air valve, car bearings, bearings of water pump of inside and outside circle, shaft of motor, joint pole, spinning accessories of top and bottom panel, tooth pitch of sewing machine, corrugated roller, roller silk bar, straight line slide rail, hydraulic spare parts and etc., and processing the special spare parts of particular equipments and many other products. |

Factory

With 40 years experience in Superabrasive industry, E-Grind Abrasives is a very reliable partner in supplying full range of Diamond and CBN grinding wheels for many industries: Woodworking, Die&Tooling, Bearing, Paper-Making, Automobile, Aerospace, Semi-Conductor...Our technology and bond systems are from US and Europe. Our producing machines are mainly imported from US, Europe, Japan and Taiwan; Specially we have 6 CNC machines for the machining and grinding our products; And the testing machines are also from Japan and Europe. All of these make our products to be premium grade with high tolerance and to meet US and Europe standard and level. Our capacity is 30, 000PCS of Diamond CBN wheels per month; Meanwhile we have more than 3000 sets of mold available; More than 4000 wheel specs; Thousands of standard wheels in stock; Customs made wheels are always available. All these make us able to supply wheels in fast delivery time: 5 days for urgent items and 14 days for standard items.