| Prod Model: |

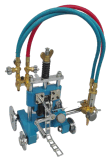

GCD4-100 |

| Power: |

Electricity |

| Cutting Gas: |

Oxygen+Acetylene or Propane |

| Cutting Material: |

Mild Steel Plate, Stainless Steel Sheet |

| Cutting Thickness: |

5-100mm |

Product Description

Product summary of GCD3-100 gas cutting machine

The oxygen cutting is widely used because of its simplicity, low price and easy operation. It is a main method for cutting carbon steel plate and low alloy metal steel plate, especially for middle thick steel plate. The surface cutting roughness could reach to 12.5 and needless to cutting processing further on common occasion. The CG1-30 (single cutting torch) and CG1-100 (double cutting torch) semiautomatic gas-cutting machine produced are multi-use machine with Ethane as its flame gas. It can do linear cutting but also circle, slide cutting as well as V shape beveling. What's more, if more facilities added, it can even be used for quench and plastic welding. Convex type guide rail,economical type

Convex type guide rail,economical type Technical parametersThis product is produced based on JB/T 7436-1994 standard. Its main technical parameters are as following: 1. Technical parameter

Technical parametersThis product is produced based on JB/T 7436-1994 standard. Its main technical parameters are as following: 1. Technical parameter| Type | GCD4-100 |

| torch No | three |

| Voltage | AC220V,50HZ |

| Steel plate thickness | 5-100mm |

| Cutting speed | 50-750mm /min |

| Cutting circle dia. | Ф200-2000 mm |

| Guide rail shape | Convex type rail |

| Machine body dimension | 470×240×240 |

| Weight | 35kg |

cutting pressure and thickness| Spec. No | Thickness | Oxygen pressure | Ethane pressure | Cutting speed |

| | mm | Mpa | Mpa | mm/min |

| 00 | 5-10 | 0.2-0.3 | >0.3 | 600-450 |

| 0 | 10-20 | 0.2-0.3 | >0.3 | 480-380 |

| 1 | 20-30 | 0.25-0.35 | >0.3 | 400-320 |

| 2 | 30-50 | 0.25-0.35 | >0.3 | 350-28. |

| 3 | 50-70 | 0.3-0.4 | >0.4 | 300-240 |

| 4 | 70-90 | 0.3-0.4 | >0.4 | 260-200 |

| 5 | 90-120 | 0.4-0.6 | >0.4 | 210-170 |

| 6 | 120-160 | 0.5-0.8 | >0.5 | 180-140 |

| 7 | 160-200 | 0.6-0.9 | >0.5 | 150-110 |

| 8 | 200-270 | 0.6-1.0 | >0.5 | 120-90 |

| 9 | 270-350 | 0.7-1.1 | >0.5 | 90-60 |

| 10 | 350-400 | 0.7-1.2 | >0.5 | 70-50 |

Advantage1.Adopting SCR technology control speed, traveling steadily2.Body of machine was cast by aluminum alloy with high intensity which is durable in use3.Torch angle could be adjusted freely back and forth, left and right

4.three torch can be cut at the same time.5.Mainly cutting straight-line and I,Y,V beveling.

6.equipped with a quick switch,can control four cutting torches at the same time,featuring convenient operation.

What's included.The gas-cutting machine is consisted of small vehicle,3 torch system, guide rail, radius bar and electric gas control.FAQ1. Q: Are you manufaturer or trading company?A: We are a factory with 28 years manufacturing experience.our main products is IGBT inverter air plasma cutter,CNC cutting machine,welding machine,beveling machine.2. Q: what certificate do you get?A: CE ,ISO,CCC and SGS.3 Q:How many days for mass production? A:15 working days after receipt of remittance.4 Q:what is your garantee period? A:1 year.5. Q:cutting material?cutting range?A:mild steel.carbon steel,stainless steel plate. effective cutting thickness is 5-100mm,circle cutting range is Ф200-2000mm.6 Q:what after-sale service do you offer?A: 24 Hours Online Service, Free spare parts for breakdown machine in warranty service7.Q:cutting speed? A:50-750mm/minute8.Q: working voltage? A:AC220V About CHDFounded in 1989, WenZhou CHD Welding Equipment Factory is China's famous cutting machine, beveling machine, welding machine and accessories manufacturer, with 3 production bases located in Shanghai, Wenzhou and Chengdu and plant area of 53,000 square meters.have passed authoritative certification such as the ISO9001 and Switzerland SGS, France BV.10 kind of products has passed the EU CE certification.Wenzhou CHD have applied for more than 10 patents, have participated in the drafting of three Chinese national standards, been rated as famous brand in Shanghai. With marketing and service agencies covering more than 70 countries.  Exhibition

ExhibitionCHD have participated in all kinds of the welding exhibitions more than 100 times since 1989 when enterprise started to run over the last decade.we attend at least exhibitions annually.

1989-2015 all the Beijing Essen Welding&Cutting Exhibitions

1989-2015 all the China welding expositions.

and exhibitions in Russia,Austrilia,India,Brazil,Vietnam&all over the mainland China.

Founded in 1989, CHD Welding and cutting equipment Co., Ltd is China's famous manufacturer of CNC plasma cutting machine, pipe and steel plate beveling machine, welding machine and accessories, with 3 production bases located in Shanghai, Wenzhou and Chengdu and plant area of 53, 000 square meters. Have passed authoritative certification such as the ISO9001 and Switzerland SGS, France BV. 10 kind of products has passed the EU CE certification. Wenzhou CHD have applied for more than 10 patents, have participated in the drafting of 3 Chinese national standards and own 9 invention patents. CHD has been rated as famous brand in Shanghai. With marketing and service agencies covering more than 70 countries. The sales quantity of cutting machine are more than 10000 every year.

CHD have participated in all kinds of the welding exhibitions more than 100 times since 1989 when enterprise started to run over the last decade. We attend at least 6 exhibitions annually.

1989-2015 all the Beijing Essen Welding&Cutting Exhibitions

1989-2015 all the China welding expositions.

And exhibitions in Russia, Austrilia, India, Brazil, Vietnam&all over the mainland China.