| Prod Model: |

CD6241 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Medium Size Gap Bed Lathe Machine: |

Swing Over Bed 410mm, Length 1000, 1500mm. |

| Max.Swing Over Cross Slide: |

255mm |

| Max. Swing Over Gap: |

580mm |

| Center Height: |

205mm |

| Distance Between Centers: |

1000mm(40")/1500mm(60") |

| Width Of Bed: |

250mm(10") |

| Max.Travel Of Cross Slide: |

210mm(8 1/2") |

| Spindle Bore: |

52mm(2") |

| Power Of Main Motor: |

2.2/3.3kw(Optional 3/5.5kw) |

| Power Of Coolant Pump: |

4p,3pH 90W |

| Type: |

Horizontal Lathe |

| Processing Accessory: |

Chuck CNC Lathe |

| Power Source: |

Electric |

| Controlling Mode: |

Artificial |

| Automatic Grade: |

Semiautomatic |

| Setting Mode: |

Floor-type |

| Precision: |

High Precision |

| Tool Holder: |

4-Position Tool Post |

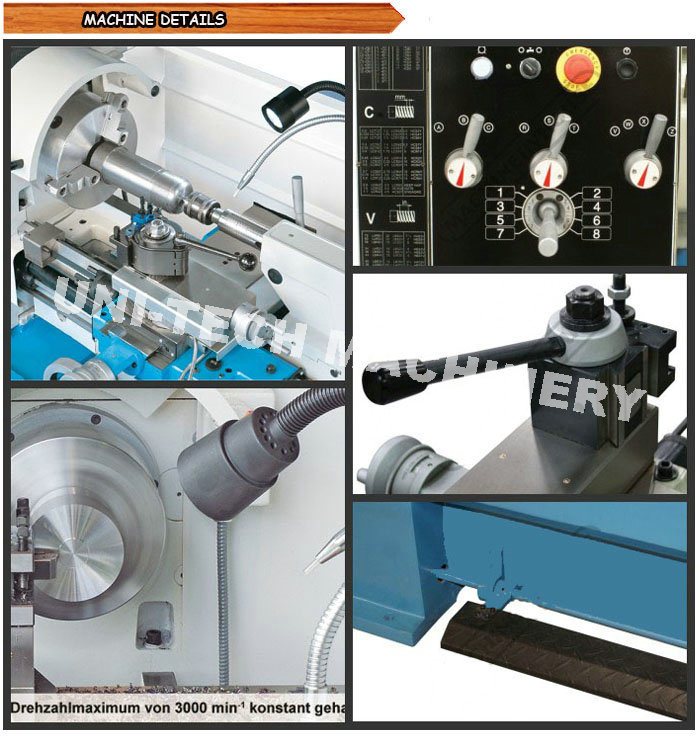

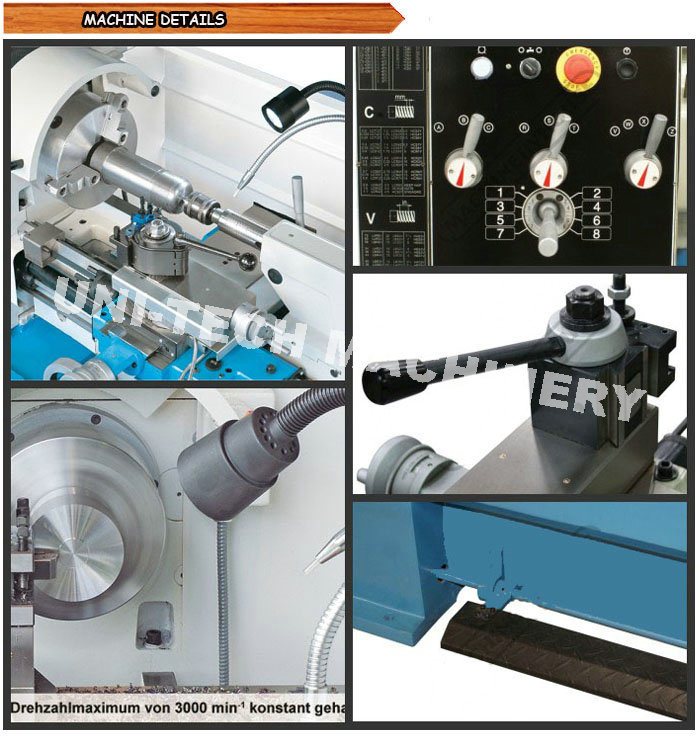

Product Description

The specification of Horizontal Lathe Machine

CAPACITY

Swing over bed 410mm(16")

Swing over cross slide 255mm(10")

Swing in gap 580(23")

Length of gap 250(10")

Distance between centers 1000mm(40")

Center height 20.5"

Width of bed 250(10")

The specification of bench lathe (CD6241)HEADSTOCK

Spindle nose D1-6

Spindle bore 52mm(2")

Taper of spindle bore No. 6Morse

Range of spindle speed 16 changes 45-1800r/min

FEEDS AND THREADS

Max. Travel of compound rest 102mm(4")

Max. Travel of cross slide 210mm(8-1/4")

Leadscrew pitch 4T. P. I.

Max. Section of tool 20× 20mm(13/16")

Longitudinal feeds range 0.05-1.7mm/rev(0.002"-0.067"/rev)

Cross oeeds range 0.025-0.85mm(0.001"-0.0335"/rev)

Metric threads range 39kinds 0.2-14mm

Inch threads range 45kinds 2-72T. P. I

Diametrical pitchesrange 21kinds 44D. P.

Module pitches range 18kinds 0.3-3.5M. P.

TAILSTOCK

Dia. Of tailstock sleeve 50mm(2")

Travel of tailstock sleeve 120mm(4-3/4")

Morse taper of tailstock sleeve No. 4 Morse

Cross adjustock ± 13mm(± 1/2")

MOTOR

Power of main motor 2.8/3.3kw(3.8/4.5HP)3pH

Power of coolant pump 0.1KW(1/8HP), 3pH

DIMENSION AND WEIGHT

Overall dimension(L× W× H) mm 1940× 850× 1300 1940× 850× 1320

Packing size(L× W× H)mm 2060× 900× 1640 2060× 900× 1640

Net weight/Gross weight 1500/1750 1550/1800

The specification of bench lathe (CD6241)

STANDARD ACCESSORIES

200mm Three Jaw Chuck and Adapter

320mm Four Jaw Chuck and Adapter

300mm Face Plates

Steady Rest

Follow Rest

Thread Chasing Dial

Mt/6/4 Sleeve and MT 4 Center

Oil Gun

One set of Wrenches

Operation Manual

The specification of bench lathe (CD6241)

SPECIAL ACCESSORIES

1.200mm Driving plate

2. Quick change Tool Post

3. Taper Turning Attachment

| The specification of bench lathe (CD6241) |

| Model | CD6241× 1000 | CD6241× 1500 |

| Max.swing over bed | Φ410mm(16") |

| Max.swing over cross slide | Φ255mm(10") |

| Max. swing over gap | Φ580mm(23") |

| Center height | 205mm(8") |

| Distance between centers | 1000mm(40")/1500mm(60") |

| Width of bed | 250mm(10") |

| Max.section of tool | 20mm×20mm(3/4"×3/4") |

| Max.travel of cross slide | 210mm(8 1/2") |

| Max.travel of compound rese | 140mm(5 1/2") |

| Spindle bore | Φ52mm(2") |

| Spindle nose | D1-6 |

| Taper of spindle speed | M.T.#6 |

| Range of spindle speed | 16changes25-1800r/min |

| Leadscrew pitch | 4 T.P.I. |

| Range of metric longitudinal feeds range | 0.05-1.7mm/rev(17 Nos) |

| Range of inch longitudinal feeds | 0.002"-0.067"/rev (17 Nos) |

| Range of metric cross feeds | 0.025-0.85mm/rev (17 Nos) |

| Range of inch cross feeds | 0.001"-0.0335"/rev (17 Nos) |

| Range of metric threads | 0.2-14mm(NO. 39) |

| Range of inch threads | 2-72 T.P.I.(NO. 45) |

| Range of Diametrical pitch | 8-44D.P.(21Nos) |

| Range of module pitches | 0.3-3.5 M.P.(18Nos) |

| Dia. of tailstock sleeve | 50mm(2") |

| Travel of tailstock sleeve | 120mm(4 3/4") |

| Morse taper of tailstock sleeve | M.T.#4 |

| Power of main motor | 2.2/3.3kw(optional 3/5.5kw) |

| Power of coolant pump | 4P,3PH 90W |

| Overall diamension(L*W*H) | 1940mm×850mm×1320mm |

| Packing size(L*W*H) | 2070mm×940mm×1600mm |

| N.W/G.W | 1550kg/1760kg |

Tengzhou Uni-tech machinery Co. Ltd, specially in the range of supplying different machines, machine tools, machinery accessories. With long time exporting machines experience, we can not only supplying our customers stable quality products, but also more excellent service.

Supplying source:

1. As an machinery supplier for many years, we are aware whose quality is acceptable, whose quality is poor, we always can meet our customers requests, precisely. With the long time and deep relationship with the factory, as exporter, we can get better prices, which play a key role in the market competition...Ours development coming from customers growing.

2. We also follow the products developing, always can recommend the newly developed products to our customer to meet the changing market.

3. With the experience, we also can meet customers products improvements, for

Some place modifying, in order to meet exactly customer requests.

Quality Control

We have our own engineer who has more than years of working experience and is professionally trained. Our trained engineers can help customers on behalf of company not only inspect goods before shipping but also track all links of production process.

After-sales service

We guarantee that all products could be used with free of defect in one year from the date of purchase. During our guarantee period, all customers enjoy free service of repairing of changing any defective parts. This guarantee does not apply to those defects directly or indirectly due to improperly use and repairs or maintenance.

Customer-service

We can provide customers the fast after-sale service warranty. In order to meet this point,

What your requests, including the spare parts posting requests, quality modifying, price inquiry, delivery time checking, we will try our best to feed back within 24 hours.

CUSTOMER PROFITS IS ALWAYS THE FIRST, AS OWING TO CUSTOMER NEEDING, EXPECTING, INFLUENCE, UNIQUE, WE MUST BE CONSIDERATE, FASTER, FLEXIBLE, THEN WE CAN HAVE BRIGHT FUTURE.

We are engaged in manufacturing and supplying all kinds of metal workings machines, machine tools and accessories, measuring tools… … . With rich experience in exporting and manufacturing, we are always pay more attention to the Fast inquiry replying, Strict quality control, On time delivery time, Quick after-sales-service, also for the best price for our customers, we also have more certificate such as ISO, CE. Hope to take this chance to enter into direct business with you.

*manufacturing and supplying all kinds drlling and milling machine, turret

Milling machine,

*manufacturing all kinds of gap bed lathes and supplying different accessories.

*** manufacturing all kinds of manual metal sheet products